Why is it necessary to engrave identification on medical devices?

The UDI (Unique Device Identification) standard is a standard for identifying medical devices in healthcare settings by assigning, tracking, and managing information about the devices throughout the supply chain and use. UDI typically includes information such as the code, series number, production date, and quantity of the products. The UDI standard ensures consistency and accurate tracking of information about medical devices. Medical devices and surgical instruments manufactured for the US market need to be uniquely identified according to this standard.

The EU has also issued a similar standard called the MDR (Medical Device Regulation). The EU also requires all medical devices and surgical instruments to be identified and have information specified before manufacturers export them to any EU member countries.

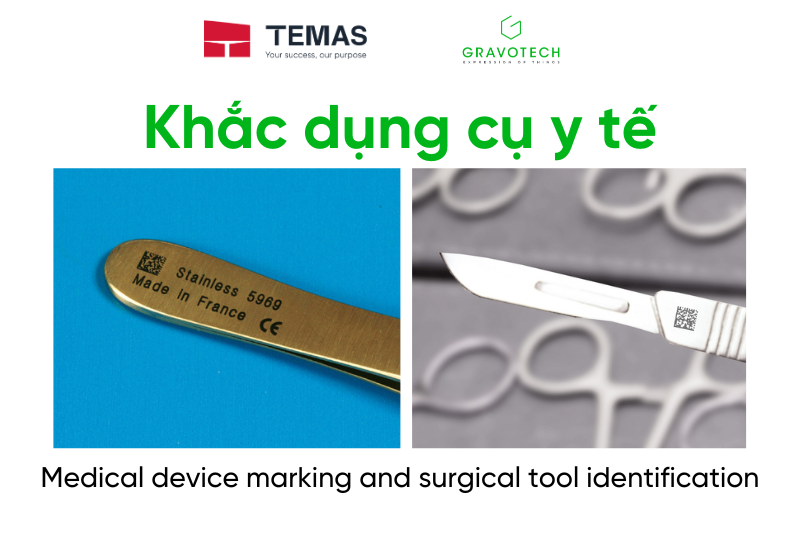

As an expert in traceability marking solutions for over 30 years, Gravotech provides laser marking solutions on medical devices to assist you in complying with UDI and MDR standards for your products. Our laser marking machines are ideal for medical devices, prostheses, and other surgical instruments (surgical knives, clamps, forceps, scissors, etc.).

Traceability of steel surgical instruments

You can marking logos, datamatrix codes, serial numbers, or any other necessary information to identify a medical device. Manufacturers of medical equipment and healthcare institutions are increasingly regulated by strict guidelines, including standards such as UDI and MDR, as well as other regulations related to identification and traceability of origin and device information. Therefore, the demand for marking on medical instruments is constantly increasing.

Datamatrix engraving on surgical instrument

Marking prosthetic parts, such as titanium and stainless steel replacements for body parts

Prosthetic parts (such as prosthetic legs, arms, bones, etc.) are mainly used to replace a part or entire bone in the human body, hence they need to be very durable. Commonly used materials are metals, ceramics, or high cross-linked polyethylene. Gravotech marking machines can perfectly engrave on these materials without affecting the integrity of the material, resulting in high contrast and durable markings that meet laboratory standards.

Benefits of identifying medical devices and instruments with our laser engraving machine:

1. Better security

- The Gravotech marking machine is perfect for marking on medical devices and surgical instruments because this solution ensures that the marking process does not introduce bacteria into the engraved tool (compared to directly marking on the tool). We provide you with a safe and efficient identification marking process.

- Compliance with UDI and MDR standards

- The engraved markings can withstand sterilization processes, disinfectants, and exposure to acids and heat without corroding or damaging the engraved tool.

- The marking does not penetrate the material nor alter it (such as stainless steel, polymers, titanium, etc.).

- The marking mes not affect the cleanliness of the medical device, ensuring that the instrument remains undamaged and free from contamination.

Traceability of steel surgical instruments

2. Better identification

- Laser marking is an effective solution to record complete origin information of tools, easily accessing information.

- Effectively combating counterfeit goods.

- Consistent marking on all types of tools, regardless of their complexity

Medical equipment traceability

3. Higher quality

- There's no longer a need to use expensive and environmentally polluting labels because laser marking can meet labeling requirements better and more durable. Laser markings are very clear, detailed, precise, and resilient on any medical tool and equipment.

- It can be engraved on various medical materials, different materials, and can meet the diverse applications and market demands.

Different medical equipment marking

4. Intelligent software

- The operating mode allows the marking machine to adjust marking parameters based on the material and shape of the object without the intervention of the operator.

- The integrated operating software is highly flexible, allowing users to customize according to the customer's marking needs.

- Once properly set up, the software will automatically run in the correct sequence, reducing the chances of errors caused by human operation.

- The operator only needs to enter the measurements and material type of the part to be engraved, and all remaining steps will be automatically performed by the marking machine with just one press of a button. The measurements and material of the part can be manually entered or scanned using a barcode scanner.

- Easy inspection, repair, and error correction of markings are facilitated.

Intelligent marking software

Our laser marking solutions

Fiber, Green, and Hybrid laser marking are the most suitable for medical tool engraving applications. You can choose a compact marking station or an integrated marking machine on your production line, depending on the type of manufacturing you have.

If you want to mark your products in small to medium quantities (such as a clinic, hospital, or medical equipment store), a laser marking station is a suitable solution for your needs.

If you produce medical equipment in large quantities and require batch marking, a directly integrated marking machine on the production line will be more effective.

Discover Gravotech laser marking machines here

More images about medical device traceability by our Gravotech marking machines:

Read more

Read more