What is the VISCO Vision System?

VISCO is an advanced industrial vision system that utilizes image processing technology to analyze and determine the position of products on conveyors or within the robot’s working space. This system can identify shape, color, size, and even detect the smallest defects on products, providing accurate data for robotic picking.

VISCO machine vision system demo

Challenges in Robotic Picking Applications

- Identifying products with varying orientations: Products on a conveyor may not always be aligned in the same direction.

- Detecting situations where robots cannot pick products: Identifying overlapping or stuck products that may prevent successful picking.

- Distinguishing front and back sides: Ensuring that the robot picks up the correct side for optimized assembly or inspection processes.

VISCO Technologies’ Solution

1. Precision Alignment and Robotic Picking Support

To enable robots to pick products accurately, the VISCO system employs Robot Finder, combined with its proprietary GradFinder® algorithm. This combination ensures precise coordinated delivery, allowing robots to execute tasks flawlessly.

Advantage 1: Identifying Top and Bottom Surfaces of Products

Rather than requiring all products to be uniformly oriented, the system can be "taught" to differentiate between the top and bottom surfaces of individual items. To ensure high accuracy, the system employs a two-step search process:

- It identifies unique product features, such as characters or distinctive markings.

- Based on these features, the system determines which side is facing up and whether the product is suitable for picking.

The robot is scanning to recognize the product

This process minimizes errors and ensures that the robot picks only processable products.

Advantage 2: Detecting Overlapping Products

The system enables simultaneous detection of multiple overlapping products, significantly reducing alignment time compared to traditional methods. With just a single scan, the system can determine the position of multiple products and output their coordinates via a network or serial communication port.

Advantage 3: Robot-Compatible Coordinate Output

The VTV-9000 system is designed to be compatible with various robot types. In image processing, the top-left corner of an image is typically used as the coordinate origin.

Machine Vision Inspection System VISCO VTV-9000

However, different robots may adopt different coordinate systems. The VTV-9000 offers flexible coordinate output customization, ensuring seamless integration with different robotic platforms.

2. Simple Configuration

Configuring the system is easier than ever with just a few marking operations. Users can:

- Easily define the coordinate system.

- Set the number of detection points.

- Select the axis direction or rotation angle for transmitting coordinate information from detection points to the robot.

Detecting overlapping products

Training search models for both top and bottom surfaces is also highly convenient, allowing for fast adaptation to various product types.

3. Applications (Specialized Inspections)

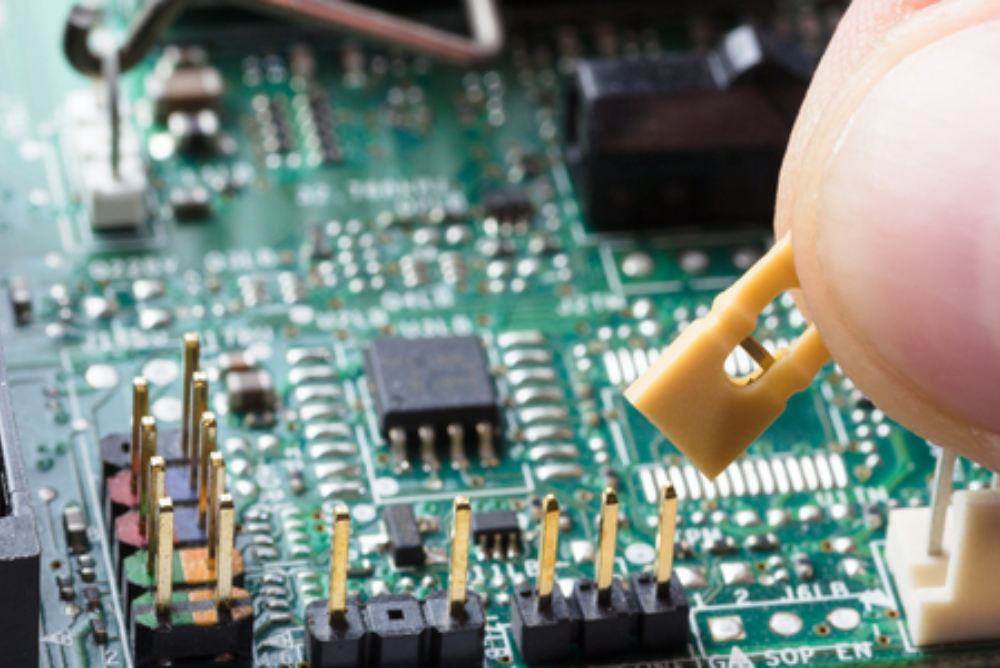

Connector Inspection

The system precisely measures the spacing between similar connectors, ensuring uniform assembly. Additionally, it can measure the distance between adjacent electronic component pins, preventing overlapping or excessive gaps. Moreover, it detects misalignment in connectors within electronic devices, identifying assembly errors or production defects.

BGA Inspection

The system analyzes the alignment of solder ball arrays, calculating intersection points to determine exact solder ball positions. This enables detection of defects such as misalignment, missing balls, or solder bridging.

The VTV-9000 system is not limited to BGA inspection, it offers versatile customization for a wide range of inspections, from electronic components to small mechanical parts.

3D Inspection

The VISCO system integrates Super-Focus Cameras, Telecentric Lenses, and VISCO Optical Technology with traditional stereoscopic measurement, enabling high-accuracy and high-speed height inspection.

VISCO offers optical solutions in the form of 3D_OIM modules, simplifying deployment with pre-configured optical systems. These modules cater to specific applications, including:

- Dual-camera 3D_OIM: For card connectors and other flat-lead products.

- Single-camera 3D_OIM: For automotive connectors and pin-lead products.

Character Inspection and OCV (Optical Character Verification)

The VTV-9000 system goes beyond merely detecting character presence, it evaluates character quality and accuracy. It supports diverse inspection tasks, identifying a wide range of defects, from minor misprints to major errors.

Efficient and Flexible Character Learning:

- For precise inspection, the system must "learn" character patterns. The VTV-9000 supports training up to 10,000 characters, with intuitive tools for easy and rapid setup.

- The Blob Character Recognition feature allows the system to automatically detect and extract characters from images, reducing operator workload.

Enhanced Inspection with Integrated Tools:

The system’s flexibility is further enhanced by its ability to integrate with other inspection tools, such as packaging or adhesive inspections, enabling the creation of comprehensive inspection workflows.

High-Accuracy OCV:

Optical Character Verification (OCV) is a powerful feature of the VTV-9000, ensuring character accuracy by comparing detected characters with learned templates. The system supports multiple font training and provides efficient font management tools.

Robot Finder

High-Accuracy Detection with GradFinder®:

To ensure robots pick products accurately, precise coordinate guidance is required. Robot Finder utilizes VISCO’s proprietary GradFinder® algorithm for alignment, ensuring high detection accuracy.

Distinguishing Top/Bottom Surfaces:

Unlike conventional methods requiring uniform product orientation, Robot Finder can be trained to differentiate top and bottom surfaces, making it highly adaptable for various applications.

Judge top/bottom sides

Multi-Product Scanning:

The system significantly reduces alignment time by detecting multiple products in a single scan, exporting coordinates via network or serial ports.

Robot-Compatible Coordinate Output:

The VTV-9000 supports multiple robot platforms by providing flexible coordinate output settings, ensuring seamless integration.

Coordinate output suitable for the robot

Numerical Inspection

Handling Various Conditions:

- Accurate Product Counting: The system counts only designated products, filtering out unnecessary items, even in overlapping conditions.

- Processing Complex Products: It effectively handles rotated, overlapping, or varying-sized products.

Efficient Applications Across Industries:

- Electronic component counting: Ensures correct component quantities in PCBs and production lines.

- Wire core counting: Verifies the number of cores in cables and electrical wires.

- Pill counting: Ensures accurate pill quantities in blister packs or bottles.

O-ring Inspection

The TrackingEdge tool allows fast and accurate detection of deformations and missing sections, making it ideal for applications requiring high precision and efficiency.

O-ring

With outstanding precision, speed, and flexible customization, the VISCO vision system is the optimal solution for robotic precision picking applications across various industries. From recognition, classification, and positioning to quality and quantity inspection, VISCO provides a comprehensive solution that enhances production efficiency, minimizes errors, and optimizes automation processes.

More Information: VISCO Image Processing & Inspection Systems

Read more

Read more