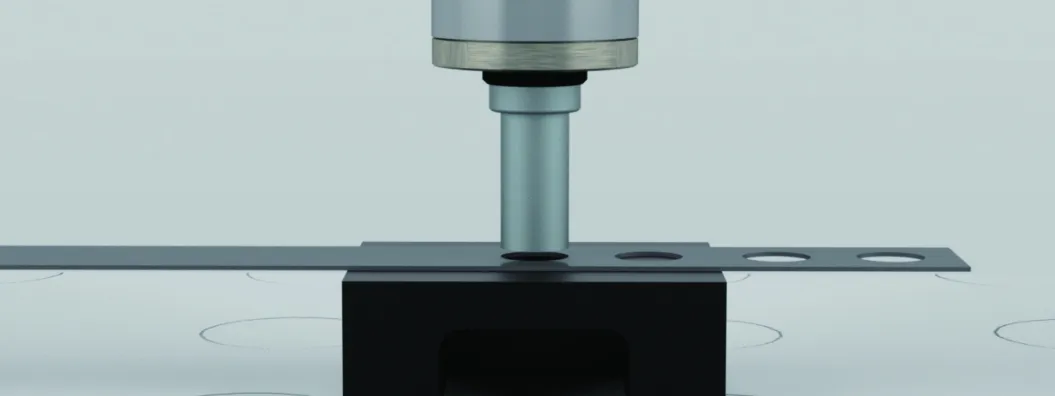

Punching is the most popular process in metal processing to give workpieces the required shape. There are many types of punching machines in the production line and most of them are using the traditional way with crankshaft which is working with a large range of force from kg to thousands of tons. Besides that Laser technology has become popular and is being used for this process also known as Laser cutting. These are the most popular way of shape cutting processes. But today we are going to mention Servo press, the best way to control the quality of the punching process. With advantages as:

- The high responsiveness of Loadcell and faster-sampling speed are the keys, the advent of peak force is in short intervals.

- Force and Distance are being monitored simultaneously and figure out NG cases such as old tools, wrong position, wrong material,... so as help to increase precision and stability of production.

- Data are being monitored in real-time, with adaptive industrial communication ports make Servo press can be easily connected to your automation system.

- Save energy up to 85% compare to Punching by the crankshaft, pneumatic or hydraulic machine...

- Compact, light, save time and cost by easy in maintenance and programming task.

- Faster in switch over between production line, change program, and checking error.

Our technical team are capable, adaptive, experience and well trained by our partners Janome - one of the top maker in Servopress technology, We Temas are confident in integration, and always find out the ideal solution with the perfect price for your requirements.

Make sure that you won't miss our latest updates by registering to become a member, or can connect directly with us via email and phone, we can help you to find out the solution for your need.