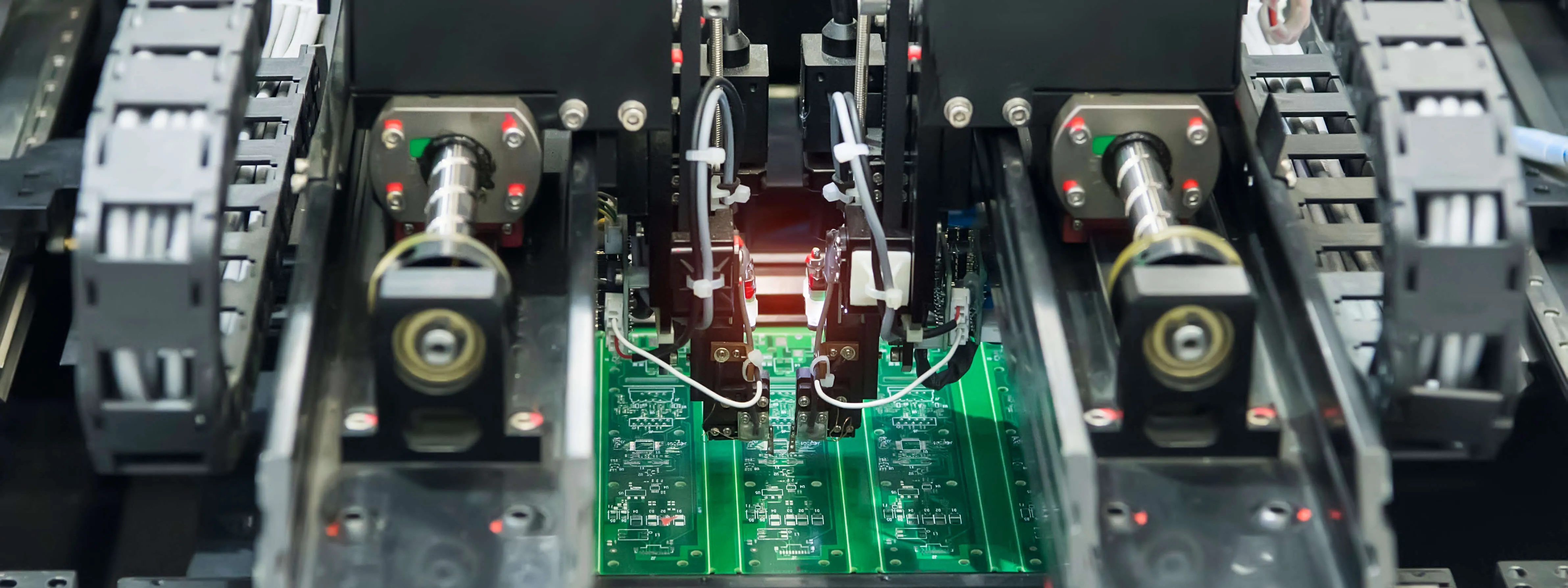

In the industry of PCB (Printed Circuit Board), most of the processes are automated with SMT technology, through this production technology PCB can be Soldering by many types like wave soldering, ultrasonic soldering, Iron tips soldering, or laser soldering... however not all of the process can be integrated into SMT line, there are some of the processes require to be done out of the line!

Technology is evolving quickly. The laser makes the possible ultrafine area and other types of soldering that are difficult using tip soldering, which drives enormous advantages. Before the adoption of new technology, read the laser soldering method to understand differences from the contact soldering method.

- High accuracy, easy to connect so as possible to integrate into the production line.

- With Diode laser technology can power up in short intervals for boost up, the soldering process now can be faster with Laser soldering than traditional Iron tips way.

- No more wasted in material or burn a lot of money on spare parts like iron tips, thanks to the contactless heat up by the laser.

- Save time and cost in maintenance.

- CCD camera included for checking process

Our technical team is capable, adaptive, experience, and well trained by our partners. We Temas are confident in integration, and always find out the ideal solution with the perfect price for your requirements.

Don't miss our latest blog posts and updates by registering to become a new member, or can connect directly with us via email and phone, we can help you to find out the solution for your need.