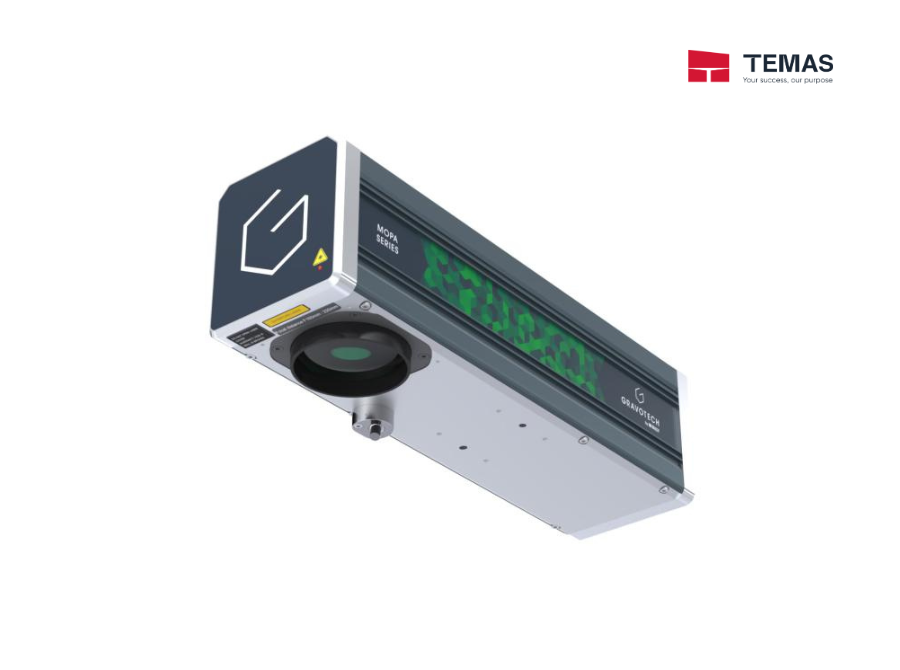

Unmatched Contrast, Precision, and Speed

Deliver exceptional marking performance with superior contrast, accuracy, and speed—even on the most challenging materials. The MOPA Laser engraver is the ultimate choice for fast, flexible, and high-quality marking in industrial applications.

PERFORMANCE

With available power outputs of 30W and 60W, the MOPA Laser ensures shorter cycle times than conventional laser technologies while achieving greater contrast on non-precious metals.

VERSATILITY

The MOPA Laser offers complete control over marking parameters with its adjustable pulse duration (2–500 ns), tunable power, and frequency settings. Whether engraving delicate plastics or tough metallic parts, it consistently delivers optimal marking results suited to each material type.

RELIABLITY

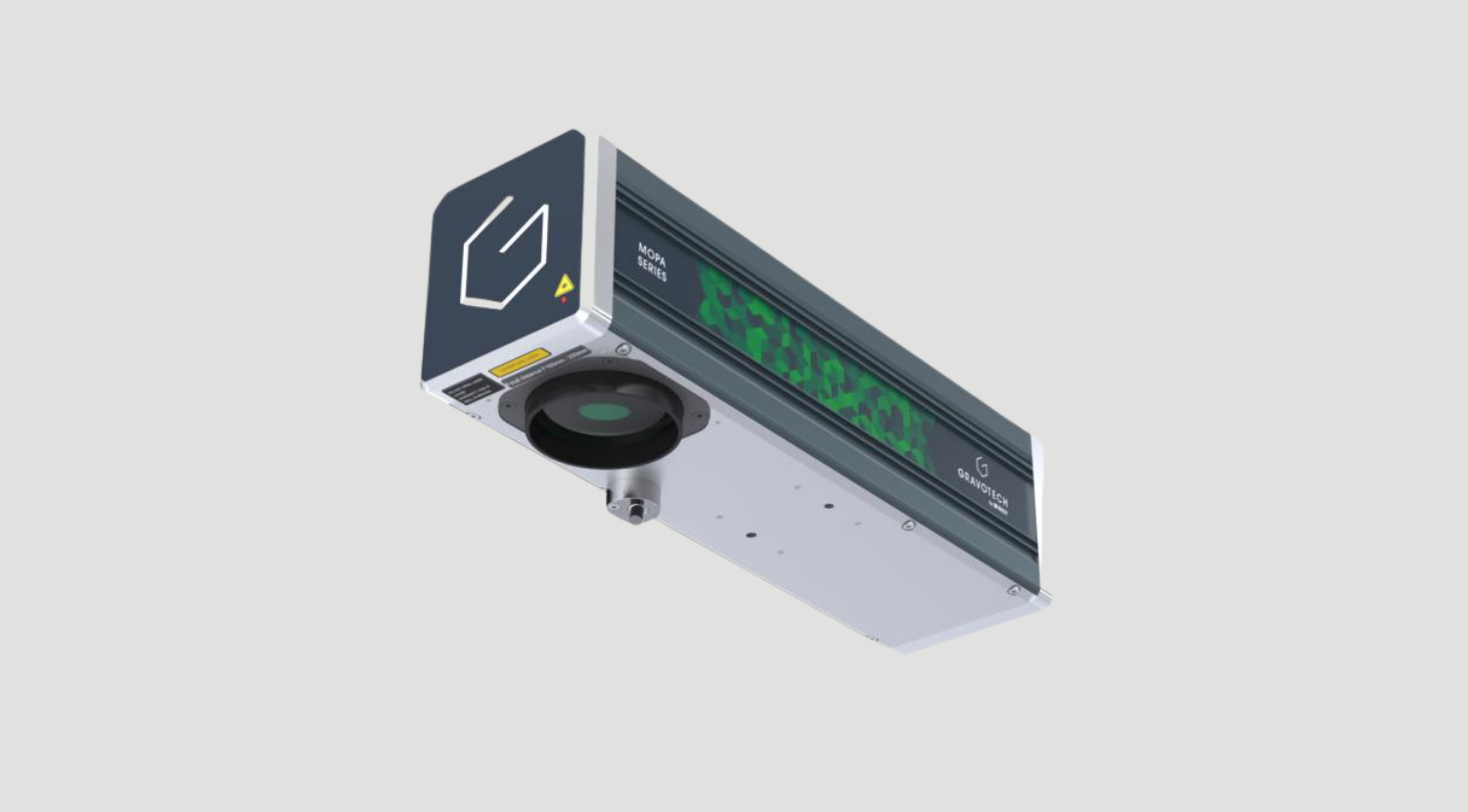

Designed for demanding environments, the MOPA Laser integrates a robust marking head and durable aluminum housing that minimizes vibration and absorbs shock. Its IP54-rated head ensures protection against dust and splashes, reducing maintenance needs and extending service life for stable, long-term operation.

Key Features

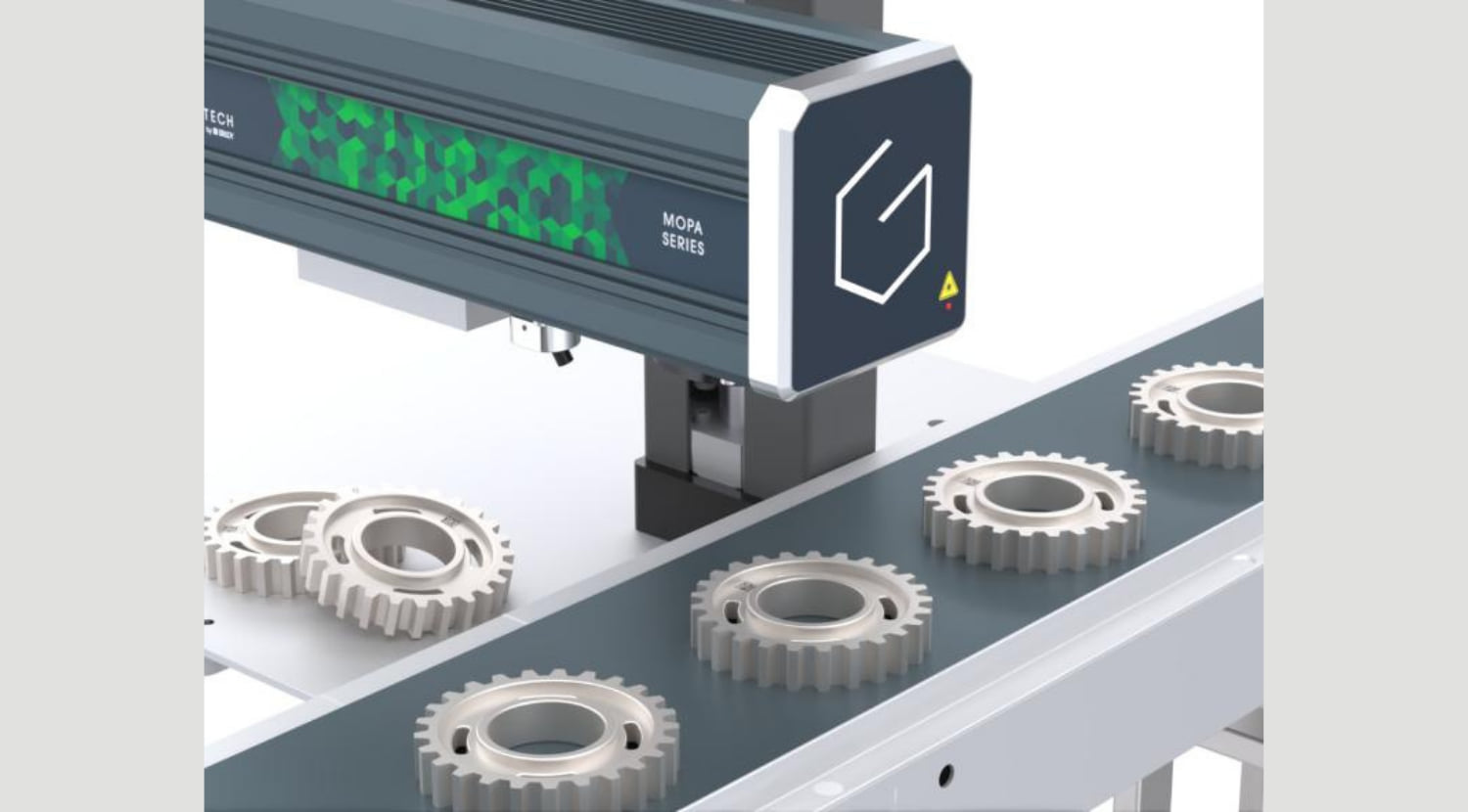

Integrable Design for Production Lines

The MOPA Laser is fully integrable into automated production lines, composed of two connected components: a marking head and a control unit (CU) linked by an optical fiber.

Thanks to its compact and streamlined structure, the marking head can be installed in tight or complex industrial spaces and at any orientation, while the CU remains safely housed inside a cabinet—up to 5 meters away from the marking zone.

A metal mesh dust filter on the CU protects electronics and the laser source from particles produced during marking processes on metal or plastic components..

Advanced Communication Capabilities

With multiple connectivity options, the MOPA Laser integrates seamlessly into smart factories. It easily interfaces with PLCs, robotic arms, and automation systems, supporting PROFINET, Ethernet/IP, Ethernet TCP/IP, RS232, as well as dedicated I/O and USB ports.

These interfaces enable real-time control and automation—no PC required.

Marking Validation Tools

Gravotech provides dedicated support for setting up marking verification and reading systems directly within production lines.

This service ensures that all markings meet required standards and guarantees product traceability.

Compatible with most industrial camera systems, these setups often include integrated lighting, autofocus, and protective lenses. When combined with the laser software, the system can:

- Detect marking presence

- Verify code content

- Trigger alerts when marking quality drops below threshold

- Allow operators to identify and remove defective parts

Note: Availability of specific functions may depend on the selected camera supplier.

Mini-inline: Compact, Safe, and Modular Marking Solution

The Mini-inline is a compact Class 1 laser module that provides operator safety without requiring a separate Class 1 enclosure. Its modular and flexible design allows mounting in any orientation and is fully compatible with robotic arms or linear actuators.

This makes it ideal for marking large or irregular parts, such as engine housings, shafts, panels, turbine blades, and other oversized components.

Paired with the MOPA Laser, it forms a compact, safe, and highly adaptive solution for precise and permanent industrial marking.

Software

Embedded on the Laser

The MOPA Laser can operate independently within a production line, generating all identification data without a computer.

This powerful embedded electronic can communicate and centralize information coming from your PLCs and database in real-time, saving you time while increasing your productivity.

Lasertrace

Lasertrace is a unique software specially designed to create marking files to be loaded in the laser system. It includes a graphic composition to add text, logos and codes like Datamatrix in your marking templates.

You can describe your marking process according to specified rules: the actions (marking blocks) to be carried out, the sequence of execution and the possibility to implement a large choice of transitions (output activations, camera blocks, variables, etc).

Accessories

Exhaust system

Laser fume extractors ensure a clean, safe, and efficient workspace by removing dust, gases, and odors generated during engraving. Without proper extraction, debris may settle between the laser and the workpiece, negatively impacting beam quality and engraving accuracy.

eZ Laser axis

The eZ Laser motorized Z-axis enables vertical movement of the marking head, accommodating parts of varying heights or shapes.

With a maximum travel of 295 mm, it ensures the ideal focal distance for precise identification. Directly connected to the CU, the eZ Laser receives marking commands and executes height adjustments automatically for consistent performance.

Specifications

| Model |

MOPA 30 / MOPA 60 |

| Laser classification |

Class 4 industrial laser marking system, possibility to switch to Class 1 by integrating it in a station or equipping with Mini-inline laser protection nose. |

| Laser Source |

MOPA 1064 nm |

| Power |

30W / 60W |

| Power Peak |

30W: 16 kW

60W: 22 kW |

| Frequency |

1 - 4000 kHz |

| Pulse duration |

from 2 to 500 ns |

| Scan speed |

Up to 3000 mm/s (118.11 in/s) |

| Beam diameter |

from 30 µm |

| Focal lenses |

F100, F160, F254, F330

|

| Marking area |

F100 (on request): 65 x 65 mm (2.6'' x 2.6'')

F160: 110 x 110 mm (4.3'' x 4.3'')

F254: 175 x 175 mm (6.9'' x 6.9'')

F330 (on request): 205 x 205 mm (8.1'' x 8.1'')

|

| Marking head cable length |

3 m – 9.8 ft

5 m – 16.4 ft

|

| IP rating |

IP54 for marking head |

| Fieldbus |

PROFINET or ETHERNET IP |

| Display |

Integrated screen with control panel for: REAL-TIME SUPERVISION, EASY DIAGNOSIS, SOFTWARE UPDATES, MEMORY BACK-UP, etc. |

| Embedded fonts type |

60+ Gravotech fonts |

| Types of codes |

All formats of barcode and 2D codes |

| Marking head weight |

8.5 kg (18.74 lbs) |

| Marking speed |

Up to 3000 mm/s (118.11 in/s) |

| Machine dimensions (L x W x H) |

458 x 130 x 135 mm

(18.031'' x 5.118'' x 5.315'') |

| Marking head installation direction |

All positions |

| Power consumption rate |

MOPA 30 : 200W

MOPA 60 : 330W |

| Rated voltage |

100 - 240 V AC |

| Operating Temperature |

10 to 40°C

(50 to 104°F) |

| Humidity level |

10-85% |

| Safety performance level |

PL=e |

| Communication |

Ethernet TCP / IP; Profinet; Ethernet IP; Dedicated I / O (SUB D37); 8I / 8O; RS232; USB (x3) |

| Control unit |

11.7 kg (25.79 lbs) |

| Robust conception |

Profiled Aluminum head

Glass lens protection

No need for cooling fan and no openings in the marking head - Dust filter for the control unit |

| Firmware update via USB port |

Restore a complete backup |