About the Customer

Our customer in this case is a well-known automotive manufacturer specializing in high-end vehicle production.

Due to the nature of high-end automobiles, the Automotive Assembly Verification process is an extremely critical stage, requiring stringent precision and exceptional aesthetics.

The Challenge

The automotive manufacturer faced two major challenges in their production process.

First, they needed to inspect over five items, each with meticulous precision in assembly correctness and appearance. Each inspection task demands high accuracy and must be performed simultaneously and quickly to ensure uninterrupted production flow.

Another major challenge is determining between qualified and defective products. In a production environment, changing lighting conditions and the presence of small details can cause ambiguity, leading to inaccurate evaluations—sometimes even rejecting a good product or approving a faulty one (false positive).

With multiple inspection tasks and the need for completion within minutes, maintaining efficiency and accuracy in the Automotive Assembly Verification process is undeniably challenging.

The Solution

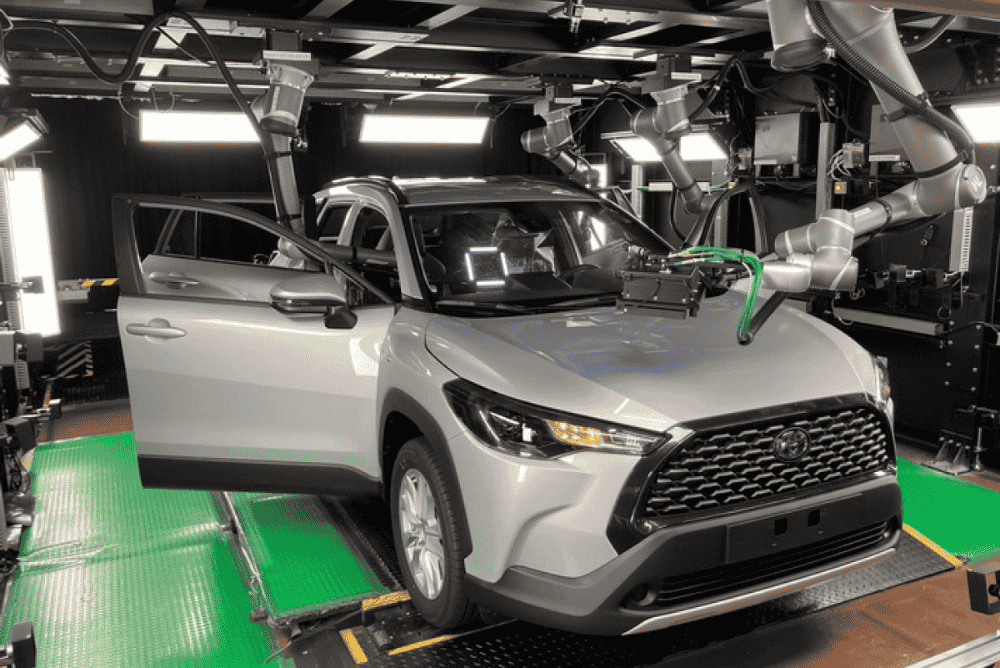

Techman Robot has designed an integrated solution based on collaborative robots (cobots) and a vision system. This solution not only automates the Automotive Assembly Verification process but also ensures unmatched speed and precision to overcome these challenges.

The solution includes::

- 4 Techman cobots (TM cobots): Programmed to perform precise inspection tasks on the production line.

- 30 external cameras (vision system): Strategically positioned, these cameras capture and analyze images of each assembled component.

This system enables over 120 tasks to be completed within 80 seconds, ensuring a fast and accurate verification process.

Detailed Inspection Process:

1. Window Decoration Style Check

- Appearance consistency: The vision system compares appearance details with the standard reference model.

- Color analysis: Cameras capture and evaluate color and surface material to ensure uniformity.

2. Lighting Cover Style Check

- Beam angle analysis: Cobots and the vision system verify the beam angle, ensuring uniform light distribution.

- Position accuracy: The system checks whether the lighting cover is installed according to design standards.

3. Anti-dust Film Check

- Presence detection: Cobots are programmed to confirm whether the anti-dust film is applied in the correct position.

- Finish evaluation: The system compares real-time images with the reference model to detect even the slightest deviations.

The Techman cobots and vision system are fully integrated with the manufacturer’s existing production and data management system, ensuring that inspection results are directly stored in the customer’s database.

Achieved Results

Implementing the Techman Cobot solution brings significant advantages to the automotive assembly verification process:

- Reduced inspection time: Previously, manual inspection was time-consuming and error-prone. With Techman cobots and the vision system, the entire verification process is now completed in just 80 seconds, significantly boosting production efficiency.

- Enhanced accuracy: The combination of cobots and a vision system minimizes human error, eliminating false positives through advanced image processing algorithms.

- Efficient system integration: A key advantage of Techman cobots is their seamless integration with existing production and data management systems. Inspection data is synchronized with the factory’s management system, allowing engineers to monitor and report results in real-time.

- Increased overall productivity and product quality: The use of collaborative robots and vision systems helps manufacturers maintain high production standards while reducing factory costs (lower operational expenses due to faster processes, reduced manual inspection labour, and minimized losses from incorrectly rejected products).

For automotive manufacturers, investing in cobots and vision systems not only optimizes the Automotive Assembly Verification process but also enhances various production stages, paving the way for sustainable development in the future.

Our team of highly experienced automation engineers is ready to support you in consulting, designing, and deploying turnkey automation solutions that are both effective and sustainable. Contact us to enhance your production process today!

Read more

Read more

![MOON LIFTER - SUCCESS STORY OF ONCHI SHOKUHIN CO., LTD. [KYOTO]](https://temas.vn/filemanage/Case Stories/Unipulse/Moon Lifter/cau_chuyen_thanh_cong_moon_lifter_3.jpg)