Since their introduction into various business sectors and industrial processes, cobots have significantly boosted productivity and efficiency in the logistics and warehouse industry. This enhancement enables service providers to meet the rising demands effectively.

As cobot technology continues to evolve, coupled with the advent of Industry 4.0, supply chain efficiency and the warehouse industry can continue to reap substantial benefits.

The Role of Cobots in Warehousing

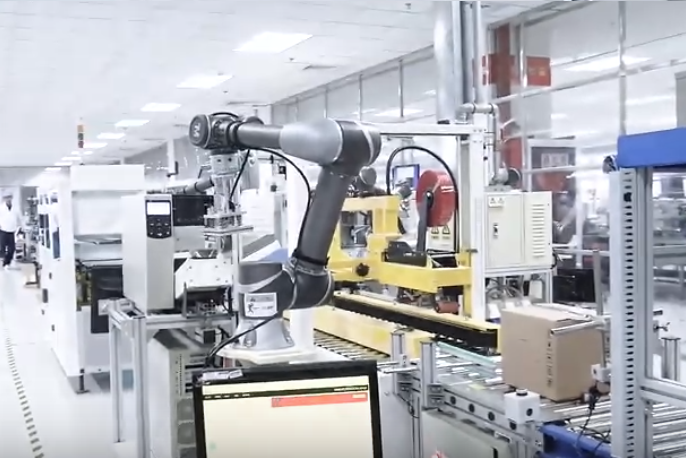

Cobots are designed to collaborate with humans in any workspace, such as warehouses and distribution centers.

They perform various tasks to minimize risks during operations efficiently, leveraging artificial intelligence (AI) programming.

In the logistics and warehouse industry, cobots provide long-term value through reliable operation in automatable tasks.

With cobots in warehouses, logistics companies can achieve higher rates of loading and unloading while reducing workplace injuries.

5 Benefits of Cobots in the Logistics and Warehouse Industry

1. Safer Work Environment and Risk Mitigation.

Warehouses are no strangers to safety hazards that can pose risks to employees and reduce business profitability. Integrating cobots into warehouse operations significantly reduces hazards and associated costs, leading to superior efficiency.

2. Reduced Error Occurrence

Errors are natural in any work process and can be addressed in various ways. Cobots with integrated precision and accuracy features add an additional layer of quality control, eliminating errors typically caused by human operators.

3. Increased Productivity

As mentioned earlier, logistics and warehouse companies can reap numerous benefits from deploying cobots, including improved throughput, faster turnaround times, and optimized processes for better efficiency.

This allows human workers to prioritize more complex tasks that directly impact revenue. With high reliability and continuous operation capability, cobots contribute to significant profit gains for businesses in the long term.

4. Lower Operating Costs

By minimizing rework due to human errors and enhancing efficiency while reducing workplace hazards, companies can significantly cut down on operational costs.

5. Flexibility in Production

Another feature of cobots advantageous in warehouse applications is their ability to collaborate on various tasks throughout the supply chain. This enables logistics and post-production companies to maximize the use of multiple collaborative robot types in operations without additional resource expenditure as demand peaks.

Automation is an undeniable factor reshaping the workplace — creating opportunities for specialized jobs and delivering high-value efficiency.

Read more

Read more

.jpg)