Challenges in Processing Paper Documents

Manufacturing and trading companies handle many paper documents daily, including purchase orders, invoices, and production inspection records. Manual data entry is time-consuming and prone to errors, directly impacting production efficiency and product quality.

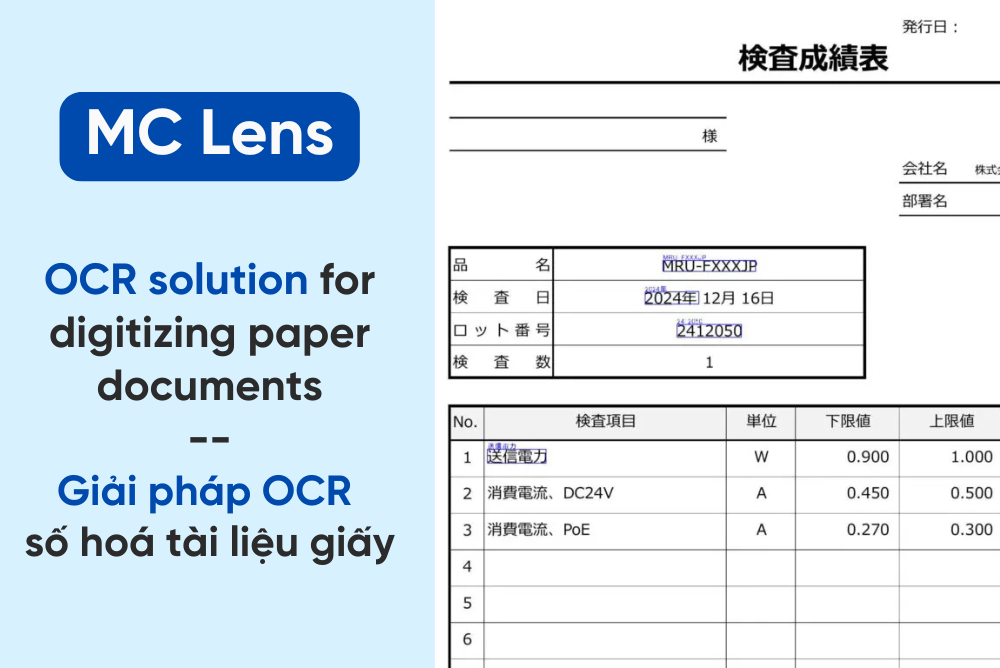

To address these challenges, the OCR solution "MC Lens" was developed to automate document digitization, reduce labor costs, and optimize management expenses.

Common Issues with Manual Data Entry

For most manufacturing and trading businesses, paper documents such as purchase orders, invoices, and quality inspection reports remain essential sources of information that must be accurately recorded and managed. However, manual processing presents several challenges:

- Time-consuming data entry: Employees must manually input data such as order numbers, shipping addresses, and unit prices into management systems, followed by visual verification, leading to inefficiencies.

- Human errors: Manual data verification increases the risk of mistakes, especially with large data volumes, resulting in rework and production delays.

- High management costs: Traditional data management systems and large-scale OCR solutions can be prohibitively expensive for businesses with limited resources

- Lack of EDI system integration: Many businesses struggle to implement Electronic Data Interchange (EDI) systems, leading to inconsistent and complex document digitization processes.

These challenges have accelerated the adoption of automated document processing solutions, including Optical Character Recognition (OCR) technology.

Understanding OCR Technology

What is OCR?

OCR (Optical Character Recognition) is a technology that converts printed or handwritten text from images, scanned documents, or PDFs into editable and searchable digital text.

How OCR works

- Image Acquisition: Documents are scanned or captured using a camera.

- Preprocessing: Image quality is enhanced, noise is removed, and text is aligned.

- Character Recognition: AI and machine learning algorithms identify letters, numbers, and symbols.

- Text Conversion: The extracted text is saved in editable formats (e.g., .doc, .txt).

Common OCR Applications

- Document digitization: Converting physical documents into searchable digital files.

- Automated data entry: Extracting information from barcodes, invoices, and purchase orders.

- Production tracking: Recognizing batch numbers, production dates, and expiration dates.

- Quality control: Verifying printed information on components to ensure assembly accuracy.

By automating these processes, OCR technology saves time, reduces errors, and enhances data management efficiency.

Introduction to "MC Lens" OCR Solution

What is MC Lens?

MC Lens is a high-performance OCR system that enables businesses to automatically digitize paper documents with exceptional accuracy and cost efficiency. Simply upload an image, and MC Lens will recognize and export the data as a CSV file.

A key advantage of MC Lens is its seamless integration into existing business workflows without requiring system modifications, enabling full automation while minimizing costs.

Seamless integration, fully automated

How Does MC Lens Server Operate?

MC Lens Server follows a simple yet highly efficient workflow:

- Step 1: Paper documents are scanned and saved in the "Request" folder

- Step 2: The system continuously monitors the folder and processes incoming documents.

- Step 3: Recognized data is extracted and saved as a CSV file in the "Result" folder.

- Step 4: Original images and processed files are stored in the "Storage" folder for tracking and comparison.

- Step 5: The CSV file integrates seamlessly with internal management systems, enabling automatic data updates and minimizing manual entry errors.

5 Key Features of MC Lens

1. Automated Data Recognition and Conversion

When an image file is placed in the "Request" folder, the system automatically scans and extracts data based on predefined rules.

2. CSV File Export

Recognized data is exported as a CSV file and stored in the "Result" folder, facilitating easy integration into internal management systems or data processing software like Excel.

3. Image Storage and Management

MC Lens Server saves both original and processed images in JPG format within the "Storage" folder, allowing users to track and verify data

4. Frame Setting

Users can define recognition zones for different document types using a simple mouse operation, enhancing extraction accuracy:

- Define Recognition Zones: Customize scan areas for various document formats.

- Extract Multiple Data Points: Capture multiple details (order numbers, shipping addresses, unit values) from a single document.

- Enhanced Accuracy: Once set, the system consistently extracts accurate data from documents of the same format, reducing manual entry errors.

5. Integration with Internal Management and EDI Systems

One of MC Lens Server’s greatest strengths is its seamless integration with existing management systems.

Digitized data exported in CSV format can be automatically imported into ERP, EDI, or Excel systems for reconciliation and data updates. This ensures data consistency across systems and enables real-time data monitoring and control.

Why Implement MC Lens in Production?

Optimizing Inspection Processes

MC Lens enhances manufacturing inspection processes by:

- Increasing efficiency: Reducing time spent on manual data verification.

- Improving accuracy: Automatically cross-referencing digitized data with original records.

- Enhancing product compliance: Minimizing inspection errors to improve quality and compliance rates.

MC Lens can read various types of information in the production environment.

Boosting Workplace Efficiency

By eliminating manual data entry, employees can focus on high-value tasks such as data analysis, process optimization, and quality improvement. Continuous data recognition and conversion enable real-time updates, ensuring businesses remain agile and responsive.

Reducing Labor and Management Costs

Reducing management and operational costs is a key factor that helps businesses create a competitive advantage.

Minimizing manual data entry processes saves time and reduces the need for manpower. Businesses can optimize resources and invest in other areas with greater strategic value.

Minimizing Errors and Enhancing Accuracy

With advanced OCR technology, MC Lens ensures high accuracy in character recognition. As a result, the risk of human errors in data entry is minimized.

The integrated Poka-Yoke function helps prevent errors arising from the data entry process, thereby ensuring that digitized data is always accurate and reliable.

Digitized Data is Easy to Use and Integrate

CSV files exported from MC Lens Server can be easily imported into Excel or integrated with existing management systems.

Digital transformation is not merely about changing the format of data storage but also a breakthrough in how businesses operate. The application of MC Lens OCR is a strategic step in the digital transformation process, helping businesses:

- Access Advanced Technology: Apply modern OCR technology to process information, thereby improving data quality and decision-making capabilities..

- Enhance Security and Control: Digitized data can be easily encrypted and securely stored, minimizing the risk of information loss.

- Improve Scalability: The system can seamlessly integrate with new technologies, meeting future business growth and expansion needs.

- Comply with Management Standards: Support businesses in achieving ISO standards for data traceability and storage.

Low Cost, Easy Deployment

One of the standout advantages of MC Lens Server is its low investment cost compared to traditional OCR systems. Businesses do not need to overhaul their existing systems but only integrate the solution into their workflow, thereby saving on initial investment costs and deployment time.

MC Lens can be used with your existing devices and systems

Application of MC Lens in Various Industries

Automotive and Automotive Parts Industry

In the automotive industry, manufacturers and distributors of automotive parts often face large volumes of orders, invoices, and quality inspection documents. MC Lens helps:

- Recognize Order and Quality Inspection Information: The system identifies specific details such as order numbers, product codes, serial numbers, technical specifications, and inspection results.

- Ensure Quality Control: Digitizing inspection sheets enables automatic data reconciliation, improving accuracy and reducing errors.

- Seamless Integration: Data converted from paper sheets to ERP/EDI systems optimizes production and distribution processes.

Electronics, Semiconductor, and High-Tech Industries

Businesses in the electronics and semiconductor industries often require strict quality control and production monitoring processes. Applying MC Lens helps:

- Quality Monitoring: Digitizing production inspection sheets ensures timely and accurate information updates.

- Integration with Automated Systems: Data from CSV files is automatically converted and reconciled with existing quality control systems.

- Cost Optimization: Reducing manual data entry steps saves manpower and operational costs.

Transportation, Logistics, and Warehousing

In the transportation and logistics sector, managing documents such as delivery notes, orders, and invoices is crucial. OCR solutions like MC Lens help businesses:

- Automate Document Digitization: Recognize information such as shipment numbers, item codes, quantities, and delivery times, converting them into CSV files.

- Support Warehouse and Delivery Management: Data exported to CSV files allows warehouse management systems (WMS) and transportation tracking systems to automatically update inventory and order status. This helps monitor the flow of goods, optimize delivery processes, and minimize data reconciliation errors.

- Optimize Logistics Operations: When information is processed quickly and accurately, managers can forecast demand, arrange, and distribute goods scientifically, thereby reducing storage time and operational costs..

Food and Beverage Industry

For businesses in the food and beverage industry, managing quality inspection documents and orders is crucial. MC Lens offers the following benefits:

- Digitizing Quality Inspection and Warehouse Registration Forms: Information such as production dates, batch numbers, inspection results, and safety parameters are accurately digitized, enabling businesses to easily track and store data.

- Product Traceability: Digitized data storage allows businesses to trace the origin of each batch, ensuring quality control from production to distribution. This is a critical factor in addressing food safety incidents.

Healthcare and Medical Industry

In hospitals, medical facilities, and nursing homes, managing medical records, prescriptions, and medical test forms requires high accuracy. Manual data entry from blurry forms or medical documents can lead to serious errors. MC Lens automates the digitization of medical documents, thereby:

- Digitizing Medical Records and Test Forms: Automatically converting medical documents such as patient records, test forms, diagnostic reports, and medical forms into digital data, ensuring accurate and quick storage of patient information.

- Saving Time: Allowing healthcare staff to focus on patient care instead of manual data entry. Additionally, this solution reduces the time spent retrieving medical records and minimizes the risk of prescription errors.

- System Integration: Digitized data can be imported into Hospital Information Systems (HIS) or Electronic Medical Records (EMR) to create a comprehensive and continuously updated medical database. This not only supports patient care but also enables doctors to quickly retrieve information in emergencies.

Retail and Distribution Industry

In the retail and distribution sector, managing invoices, order documents, and inventory control is extremely important. MC Lens helps:

- Automating Invoice and Sales Slip Conversion: MC Lens recognizes information from invoices, sales slips, and warehouse receipts, converting them into digital data in CSV format. This data is directly updated into retail management systems, enabling accurate tracking of sales, inventory, and transaction history.

- Enhancing Inventory Management Efficiency: Timely data updates ensure accurate and transparent inventory management

- Supporting Business Analysis and Forecasting: When sales data is digitized, businesses can easily perform analysis, forecast consumption trends, and develop appropriate business strategies. This helps optimize inventory, improve customer service, and enhance market competitiveness.

Key Considerations for Implementing and Applying MC Lens in Production

Assessing Needs and Work Environment

Before deploying MC Lens, businesses should thoroughly evaluate the volume and nature of existing paper documents. Clearly identifying document templates, formats, and the information to be extracted will help optimize system configuration, ensuring accurate recognition from the first attempt.

Configuring and Customizing OCR Rules

The MC Lens system allows customization of character recognition rules tailored to each document type. Businesses need to:

- Define Recognition Zones: Set up recognition frames on each document template (easily done through mouse operations).

- Configure Data Conversion Rules: Ensure critical information such as order numbers, addresses, unit values, etc., is accurately recognized and converted.

- Test and Adjust: Conduct periodic testing and adjust configurations as needed to achieve optimal performance.

System Integration and Staff Training

Once the system is deployed, integrating exported CSV files into internal management systems is a crucial step to ensure workflow continuity. Additionally, businesses should:

- Train Staff on System Usage: Help employees understand operational processes and how to handle issues when they arise.

- Monitor and Evaluate Performance: Regularly track system performance and compare it with manual data entry processes to identify areas for improvement.

More Information: MC Lens Specifications.

If your business is struggling with managing data from paper documents or concerned about errors in manual data entry, MC Lens is the optimal solution to start your production automation journey with low costs and high efficiency.

Temas is the official distributor of Mars Tohken (Japan), providing genuine and comprehensive MC Lens solutions, including consulting, trial services, and post-purchase support. Contact us to try the MC Lens solution!

Read more

Read more

.jpg)