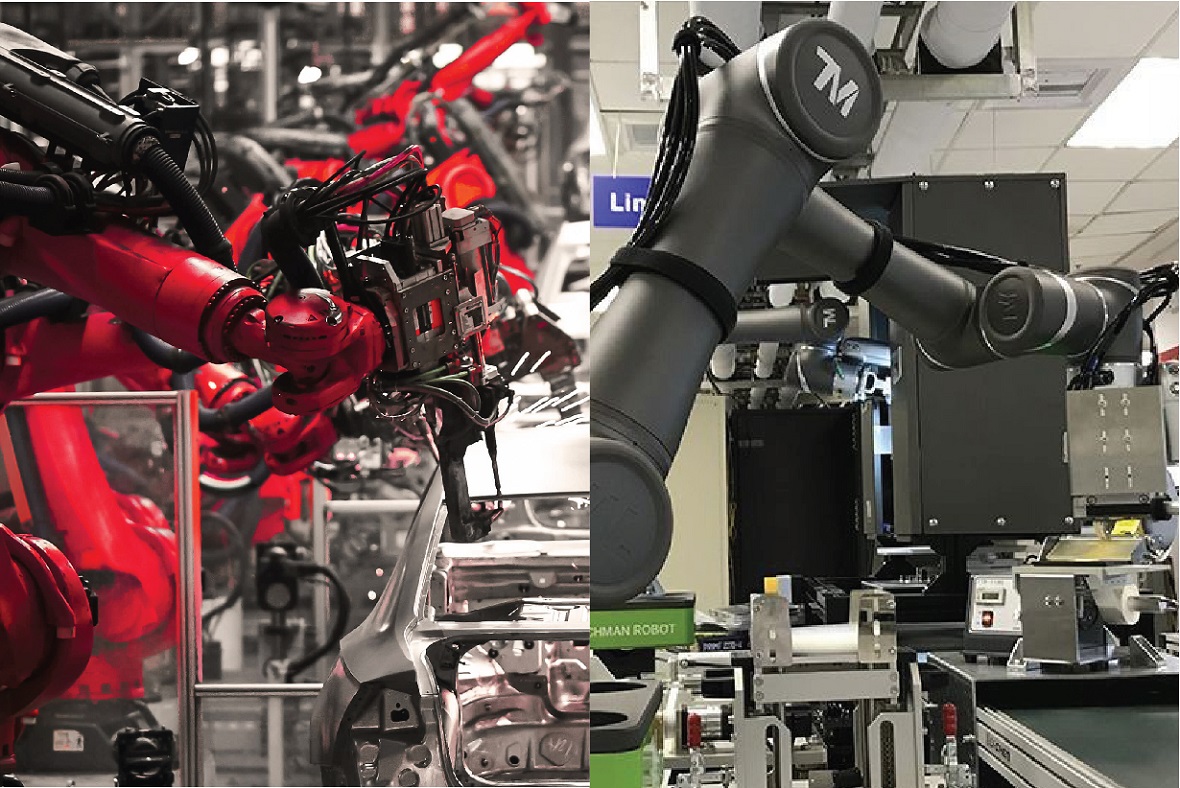

Robots and humans have been colleagues for many years, but rarely do we actually work together. This is slowly changing with the rise of collaborative robots (or cobots). Unlike traditional industrial robots, collaborative robots do not need fences or protective nets. Instead, they are designed to operate safely around humans.

Let's have a look at some key differences between Robot and Cobot:

Easy to set up

The TM robot is an example of a Collaborative Robot with very simple programming capabilities. While traditional industrial robots require advanced programming skills, TM Collaborative Robots offer TMflow drag-and-drop setup without complicated programming, making implementation very easy.

Teaching Cobots is also easy. Just putting them into servo-assisted teaching mode and instructing the arm to perform tasks, then playing back the results. We like to use the term "Cobot training" to highlight the contrast to "robot programming".

Machine vision is standard equipment

Most of the Cobot series are very simple combinations or are pre-equipped with optimal support functions for use with the vision system. In particular, Techman's Cobot series is equipped with standard hand sight.

Although vision systems for Robots have been around for a while, their integration is often more complex and less intuitive than cobots. The vision system built-in of cobots greatly increases the capabilities and range of applications.

The integrated vision function of the Collaborative Robot TM has many features such as shape matching, barcode & QR code reading, color recognition, OCR, etc - all easily configurable from the device toolbox built-in robot programming.

Safe (Because they're smart)

Industrial robots do the task "rigidly" according to what it is programmed to do, stopping only when asked to, which is why they must be equipped with protective barriers.

Cobots can have pre-set speeds and torques, which can allow them to stop if they detect something in their way. This reduces accidents and means that Cobots can be deployed, to some extent, in co-working spaces with humans.

Extremely flexible

Because Cobots are so easy to set up and use, they can be deployed wherever you need them and repurposed quickly and cost-effectively, unlike traditional industrial robots that are built with the purpose of a particular task, which is a waste of time and expense whenever robots taking a new task.

As a result, Cobots, in some ways like your flesh-and-blood workforce, are easy to retrain and reassign to new tasks.

Anywhere Applications

Cobots with outstanding advantages such as lightweight, high mobility, and ease of setup can be used in places where traditional industrial robots are too cumbersome and unsafe to easily handle such as:

- Assemble sophisticated electronic components

- Food packaging

- Place on AGVs to pick up components or handle complex assembly jobs that require high precision.

We hope the above sharing will be useful for you!

Read more about: How cobots empower humans in the manufacturing industry

Techman cobots: TM5 series and TM12/TM14 series

Read more

Read more