There are numerous rotating mechanisms around us. The more you search, the more you can find them everywhere like door handles, laptop hinges, bicycles, and PET bottle caps. Force is required to rotate or stop these rotational movements. This force is torque (or moment of force), and it is a device for measuring force in the direction of rotational motion.

Torque & Static Torque

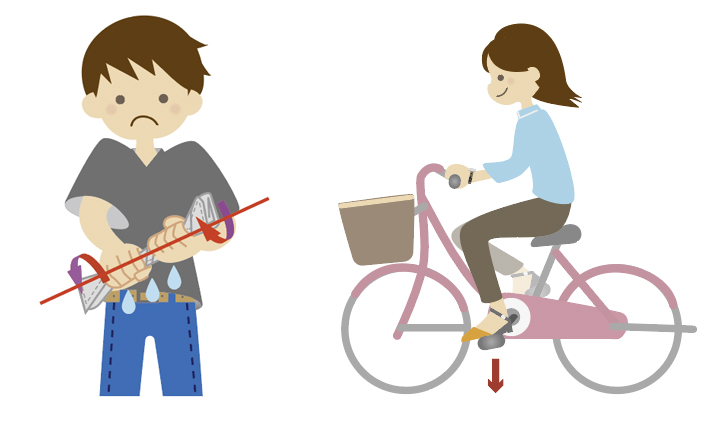

In the figures below, both forces act in the direction of rotation relative to the axis and both are torques. At some point, the piece of fabric becomes stiff and no longer rotates when balanced with the force of the hand.

Even as you continue pedaling, the pedal shaft will continue to rotate. Both have the same torque, but the values will vary slightly when measuring these forces. Specifically, creativity is needed to measure torque in these cases.

|

|

| The force acting on the fabric is Static Torque (non-rotating) | The pedal of the bicycle continues to rotate, hence the force of pedaling is Torque. |

An important aspect when measuring torque without affecting its actual value

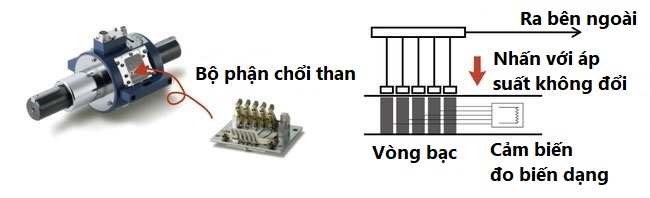

With conventional torque measuring devices, the torque wrench typically extracts torque data from itself via a slip ring. The slip ring is a power transmission mechanism that also transmits electrical signals through a commutator and carbon brush assembly arranged concentrically with the rotating body.

Typically, the shaft is fitted with 2 or 3 slip rings, which are contacted with a constant force to maintain contact and extract electrical signals. The contacts of the slip rings are made of carbon and wear due to friction with the bearing rings. Due to internal dust accumulation, the carbon brush components need replacement and the torque wrench body requires cleaning.

Moreover, pressing the carbon brush component significantly impedes the rotational movement of the shaft, thereby introducing inherent errors in the torque measuring device itself, making it unable to accurately measure torque.

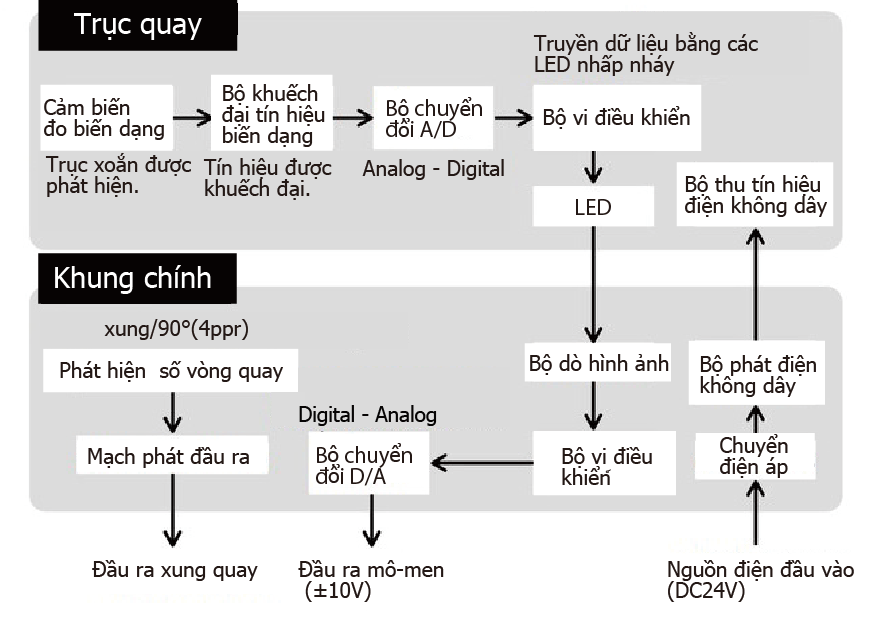

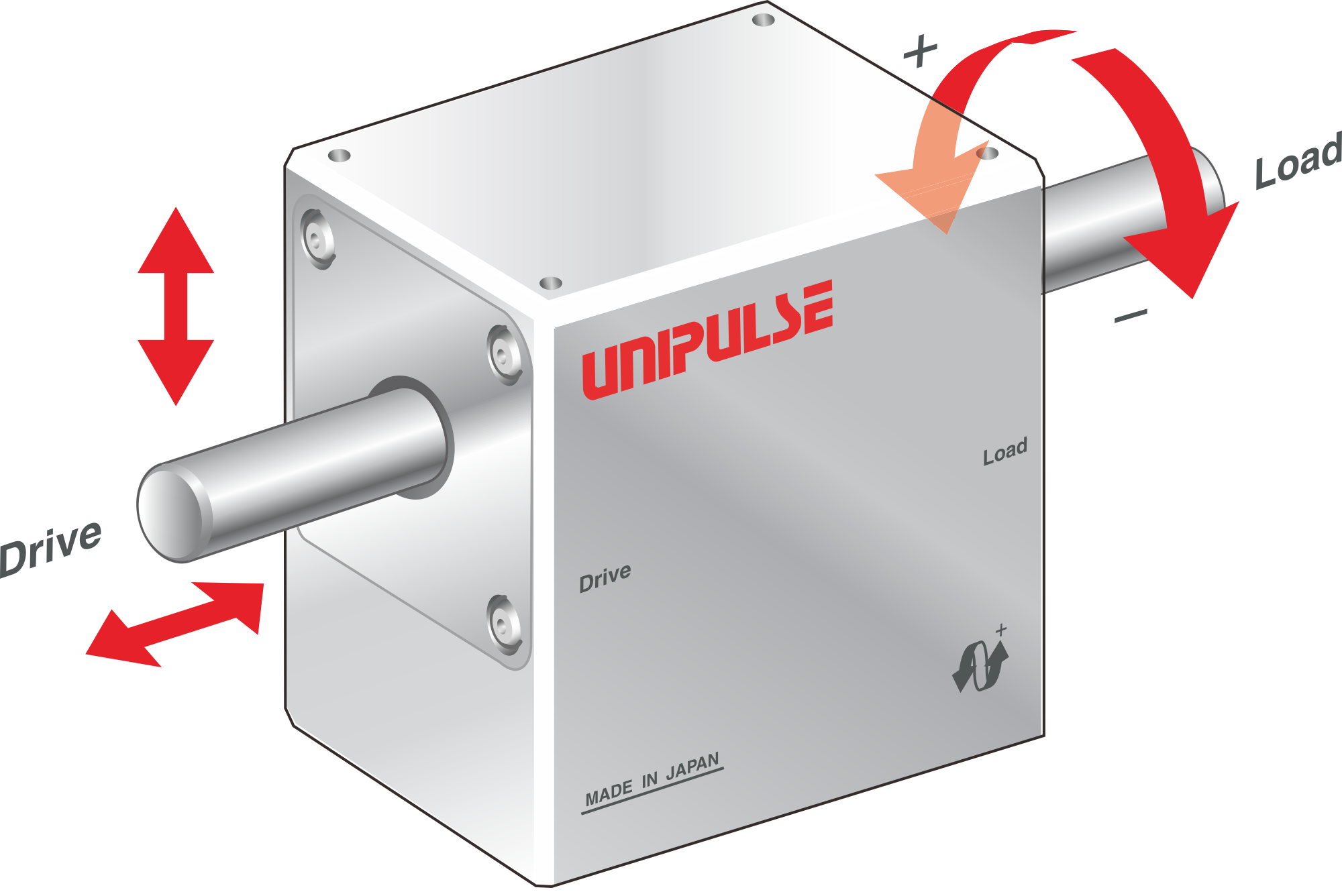

The Unipulse UTM series operates without contact, thus it does not impede rotational force

In the Unipulse UTM torque measuring device, the rotating shaft with the detection component and the fixed part transmit data without contact. This design does not hinder the rotational movement of the shaft and requires no maintenance.

Furthermore, employing digital transmission methods allows it to measure torque steadily across any rotational range. A strain gauge sensor is used for detection, achieving significantly higher accuracy compared to other detection methods.

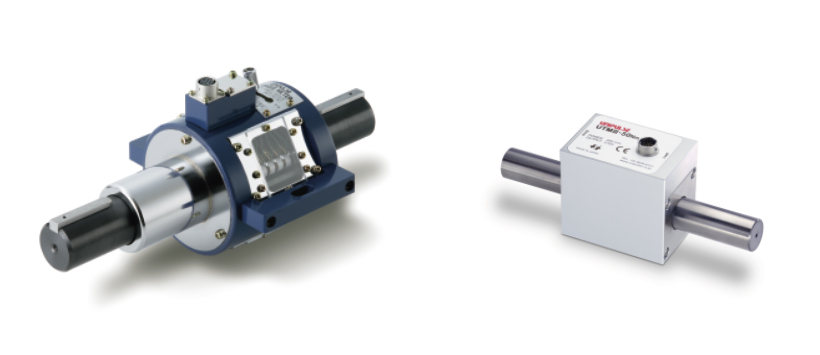

Non-contact and more compact

Non-contact transmission is technically complex but structurally simple. The body can be designed smaller, revolutionizing the typical image of 'large-sized torque wrenches.

|

|

| Contact torque wrenches (traditional) are larger. | Non-contact torque wrenches (Unipulse UTM series) are compact. |

No maintenance required

Torque wrenches with slip rings have contact points. Therefore, attention must be paid to the rotation speed and durability over time. The carbon contact points wear down and eventually disappear, which can lead to bearing failure. If this occurs, repair is impossible, and the torque wrench will need replacement. Additionally, worn carbon can scatter inside the casing and turn black. The UTM series lacks slip rings, so you can use it without worrying about maintenance.

No external amplifier needed

Traditional torque wrenches require a separate dedicated amplifier. However, as shown in the block diagram above, the UTMIII integrates the amplifier. You can measure torque during rotation simply by connecting this compact device to the shaft via couplings. The output can be adjusted to ±10V within the rated torque range.

Sample applications

There are many different features of the UTM, but here we will introduce applications that leverage the advantages of non-contact signal transmission. The advantages of non-contact transmission include:

- Very light shaft start-up

- Since there is nothing to impede shaft rotation, torque can be detected at very low values.

- Can measure over long periods without maintenance

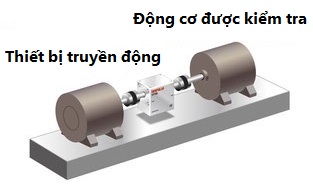

| Testing engine start-up torque | |

| To measure the start-up torque of an engine, the torque wrench itself must not add load. The UTM can accurately measure start-up torque. |  |

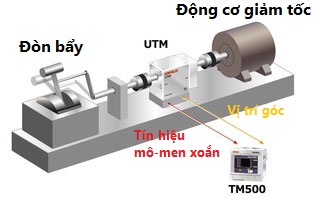

| Testing the impact force of levers or hinges | |

| Testing the torque of components related to human operations such as hinges and levers. You can quantify and manage the necessary impact force. |  |

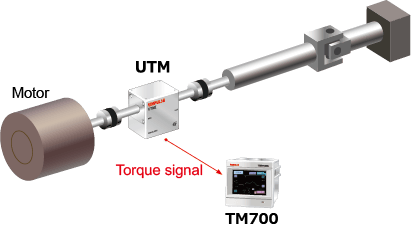

| Durability testing | |

| Durability tests are sometimes conducted over extended periods. The UTMIII requires no maintenance, making it perfect for long-term testing. |  |

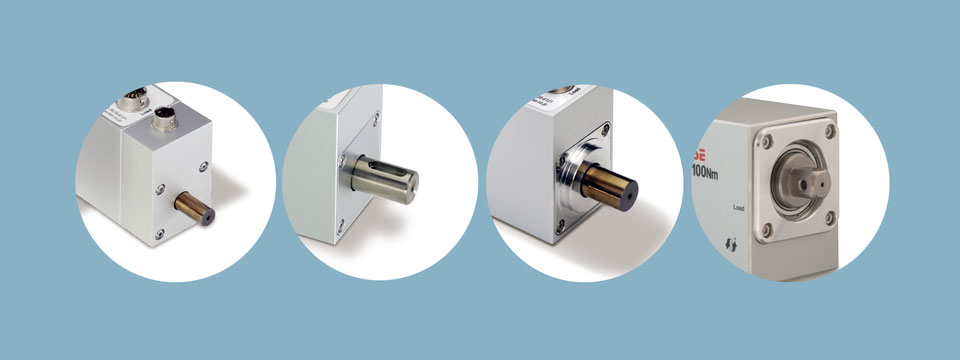

Wide Product Range and Numerous Options

Torque wrenches are essential for various needs depending on purpose and installation method. The UTM series offers a comprehensive range of capacities and customizable options to meet specific requirements. We provide a total of 13 models and 4 options ranging from small torque moments of 0.05Nm to 500Nm.

|

|||

| Angle measurement | Keyway shaft | Centering | Square shaft |

Reference

Unipulse Corporation

Read more

Read more