1. Cobot - the trending robot technology of the future

Cobots, or collaborative robots, are the key to automated production lines, in line with the trend of developing smart factories. Today's collaborative robots are increasingly empowering people because they will assist in performing heavy and time-consuming tasks and they are much smarter than traditional robots. As a result, workers and engineers can spend time doing high-value tasks such as R&D or jobs that require problem solving or decision making.

Not only does it help eliminate boring and monotonous jobs, Cobot also helps raise safety standards in the factory. Among workplace injuries, the most common injuries are caused by contact or collision with work equipment such as robots. The birth of cobot technology can meet and improve safety standards for workers, for example Techman's Cobot is integrated with smart technologies such as impact limit function that can help these cobots stop immediately when they collide with any object, preventing injury to both man and machine. In addition, you can also set a speed limit for the robot arm when it is running in the collaborative workspace, setting the safety level according to the human body parts that can be harmed by the robot in communication. TMflow's user interface. Thus, Techman Cobot fully meets the trend towards smart and safe factories and this is also an optimal choice for technical training institutions applying robotic technology in smart production, helping future engineers have access to the latest robotics technologies.

In addition, TM robot allows non-experienced users (such as students, interns or engineers, ordinary workers) to quickly learn and use immediately. Techman's cobot has replaced traditional programming with an intuitive interface and graphics with simple click-and-drag movements, backing up workflows for reuse over and over in different robotic tasks. , which makes programming and using the cobot extremely simple even for beginners. Technical training institutions can also easily apply training to their students without having to worry about inviting robotics experts to train as TM robots are easy to use!

2. Built-in camera - make the robot more flexible and intelligent

When it comes to robots, we often immediately think of heavy, bulky machines that can only perform one task such as picking up products or transporting. With the trend of building smart factories, engineers are aiming for a more efficient approach: combining the robotic arm with other utilities such as vision to make the robot operate more flexibly.

Techman cobot is equipped with an intelligent machine vision system that integrates seamlessly into both hardware and software. In other words, you already have a perfect machine vision system that is integrated directly in the TM robot without having to equip another additional vision system, minimizing time and cost for integration and production.

TM robot's machine vision system has included many programs, allowing TM robot to work flexibly with many requirements. Some outstanding modules of TM robot can be mentioned such as: object detection module (supporting pattern matching based on the image of objects, alignment and anomaly detection), advanced image processing module (supports contrast enhancement, image smoothing and thresholding, morphometry, color plane extraction and image flipping), barcode reading module (supports DataMatrix barcode/QR code/QR code reading, color grading and string matching) etc. Vision is the key to helping cobots do more, be more flexible and intelligent for complex applications.

3. AI is the technology trend and Techman cobot has it!

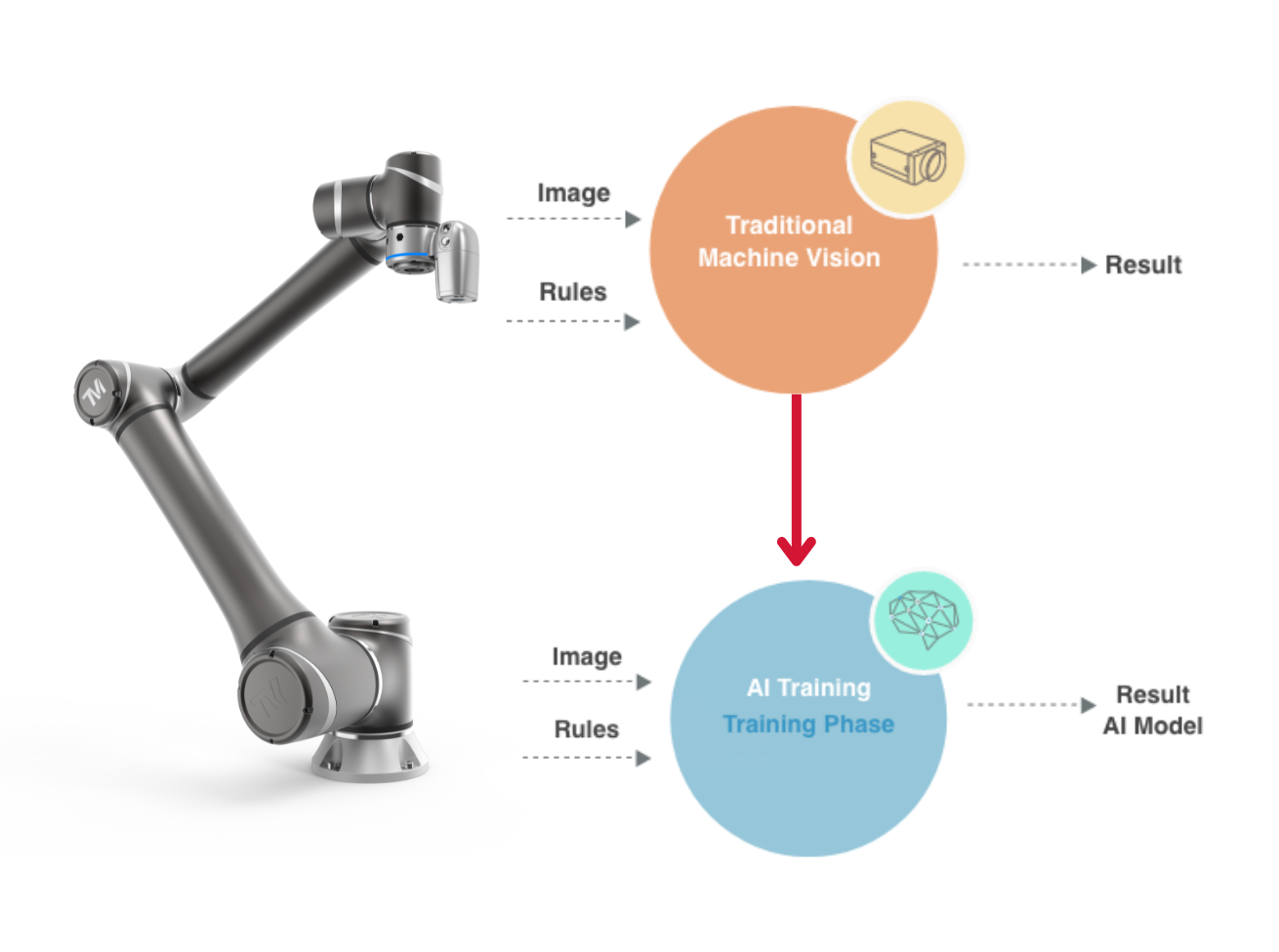

Most people often think of a robot as a passive role that can only respond to specific commands or instructions. That is true for traditional machine vision because this robotic system relies on engineers to create a set of rules to perform the tasks of recognition, detection, and classification using codes and algorithms. However, algorithms cannot cover 100% of real-world objects or situations. As a result, the accuracy of machine vision is limited.

With AI technologies introduced, cobots can create their own rules by analyzing tons of image data, creating an AI model. With more and more data being analyzed by cobots, the accuracy of this AI model can be continuously improved. AI technology is also applied to Techman's cobot lines with the TM AI+ Solution. With this solution, robots can freely learn and adapt to more complex tasks. By processing huge image data of objects through AI technology, TM robot can learn and conclude principles for self-classification or object detection. They can help differentiate ripe and unripe fruit on a farm, or visually inspect PCBs from an SMT production line to see if any components are missing. This is the outstanding technology trend of the future.

4. Combo All-in-one

With the above advantages, if you only use one robot for each application and look for external software to integrate separately, the time and cost to spend will be much greater than equipping a smart and efficient cobot like Techman Cobot.

Thus, when equipping the Techman cobot for practicing, students at technical training institutions will experience not only practical robotics practice but also access to vision techniques and artificial intelligence,.... help bring a holistic approach to using robots as well as experience the most advanced technologies for building smart factories. Technical training centers also do not have to worry too much about costs because the All-in-one integration helps to reduce the cost of purchasing materials, installation, operation and maintenance.

Read more: Why Techman robot is leading the trend of collaborative robots?

Specification: Techman Robot TM5, Techman Robot TM12-TM14

With a team of engineers with expertise, experience and long-term relationships with major partners in the field (Techman, Janome), Temas is always confident to bring the best solutions at reasonable prices to customers. specific application. Temas helps your business succeed in the industrial manufacturing industry. Visit our blogs to know more about manufacturing automation and Industry 4.0.

Read more

Read more

.jpg)