As the world of technology advances, more and more jobs are being replaced by machines or robots through improvements such as automated assembly lines.

Take manufacturing companies, for instance. For a long time, they have been using various forms of automation to streamline the production process and reduce costs. Automation can encompass anything from robots performing welding and painting tasks to assembling components.

Advantages and Disadvantages of Automated and Manual Assembly Lines

Automation brings many advantages to businesses. However, some businesses still choose manual labor in their production processes. Let's explore the pros and cons of these two choices:

- Manual assembly lines are slower and less accurate than automated ones. They require more labor, which can be costly.

- Automated assembly lines are faster and more precise than manual ones. They require less labor, which can lead to long-term cost savings.

In general, each company will decide which type of assembly line is best for their production model. However, most experts agree that automation is the future path, and companies should consider and implement it for their assembly lines.

Automation Applied in Assembly Lines

Automation has become an integral part of assembly lines, accelerating processes and producing high-quality products. There are various types of automation, each with its own advantages, whether it's fixed automation or programmable automation.

- Robots are widely used in assembly lines for their efficient and precise operation. They can work for extended hours without errors.

- Automated Guided Vehicles (AGVs) are used to transport materials and products from one place to another. These are small vehicles that move along a pre-programmed path and can transport anything from boxes to pallets.

- Industrial Internet of Things (IIoT) refers to all machines, computers, sensors, and other devices connected via the internet.

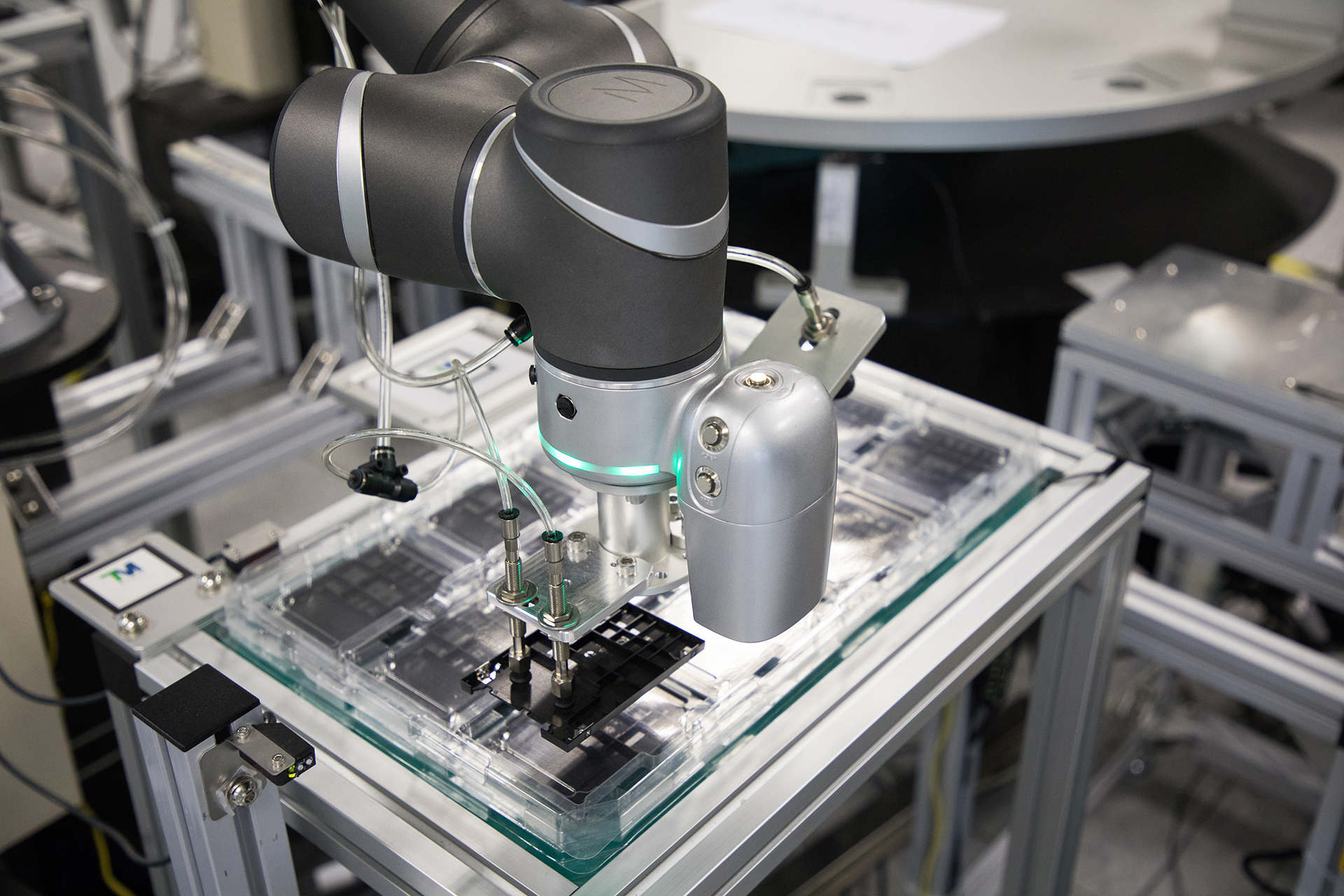

- Collaborative robots, or cobots, work alongside humans. They are safe to operate around and can be used for various tasks.

Advantages of Automated Manufacturing Assembly Lines

Speed

Automated assembly lines are significantly faster than manual ones. This means products can be produced at a faster pace with fewer labor requirements.

High Precision

This results in fewer errors and more efficient production of products.

Reduced Labor Requirements

Robots, not susceptible to fatigue, can work longer hours without errors. They can also perform specific tasks that would otherwise require manual labor.

Safety

Automated assembly lines are safer to operate, eliminating the need for manual labor in hazardous applications.

Cost saving

Automation helps save costs in the long term due to its efficiency and accuracy.

Applications of Collaborative Robots in Assembly Lines

- One of the advantages of cobots is their ability to handle both manual and automated tasks, making them versatile tools for assembly lines. They can assist humans in performing difficult or dangerous tasks that they would otherwise do manually.

- As a business owner, adopting automated assembly lines can transform how tasks are executed and contribute to reduced labor requirements, thus cutting costs.

- Machines and automated robots can also perform tasks more accurately than humans, reducing the likelihood of defective products.

- Automated assembly lines are faster than manual ones, enabling increased production within shorter time frames.

Overall, there are numerous benefits to implementing automated assembly lines in your company. If you're looking to enhance your production processes, this could be the solution for you.

With Techman Robot, a pioneering technology company specializing in robots and collaborative vision, your business can harness the potential of the future and integrate it into today's workflows.

Please explore our related articles on manufacturing automation, cobots, and Industry 4.0 for more insights.

Read more

Read more

.jpg)