Technical Information

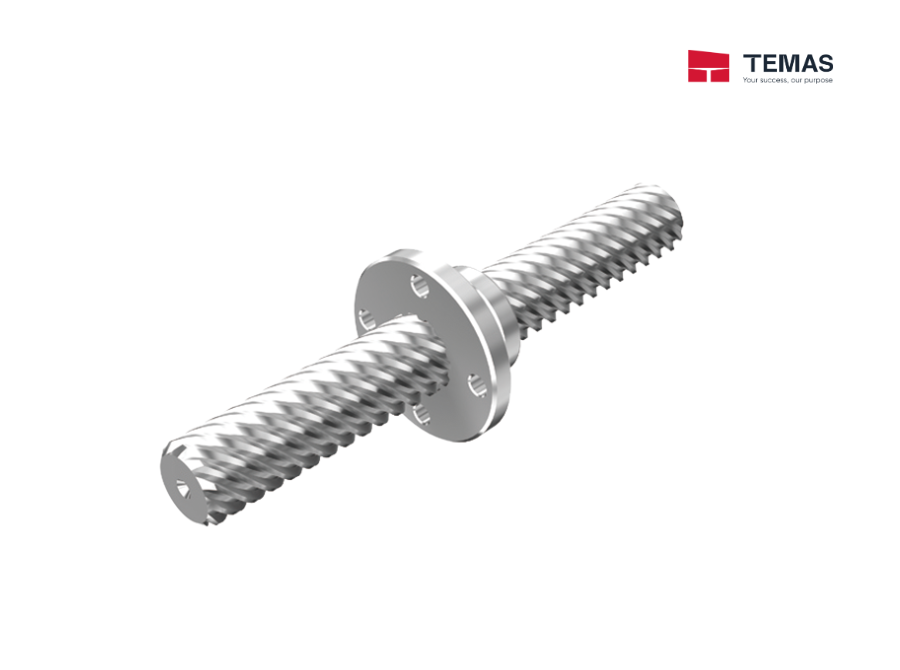

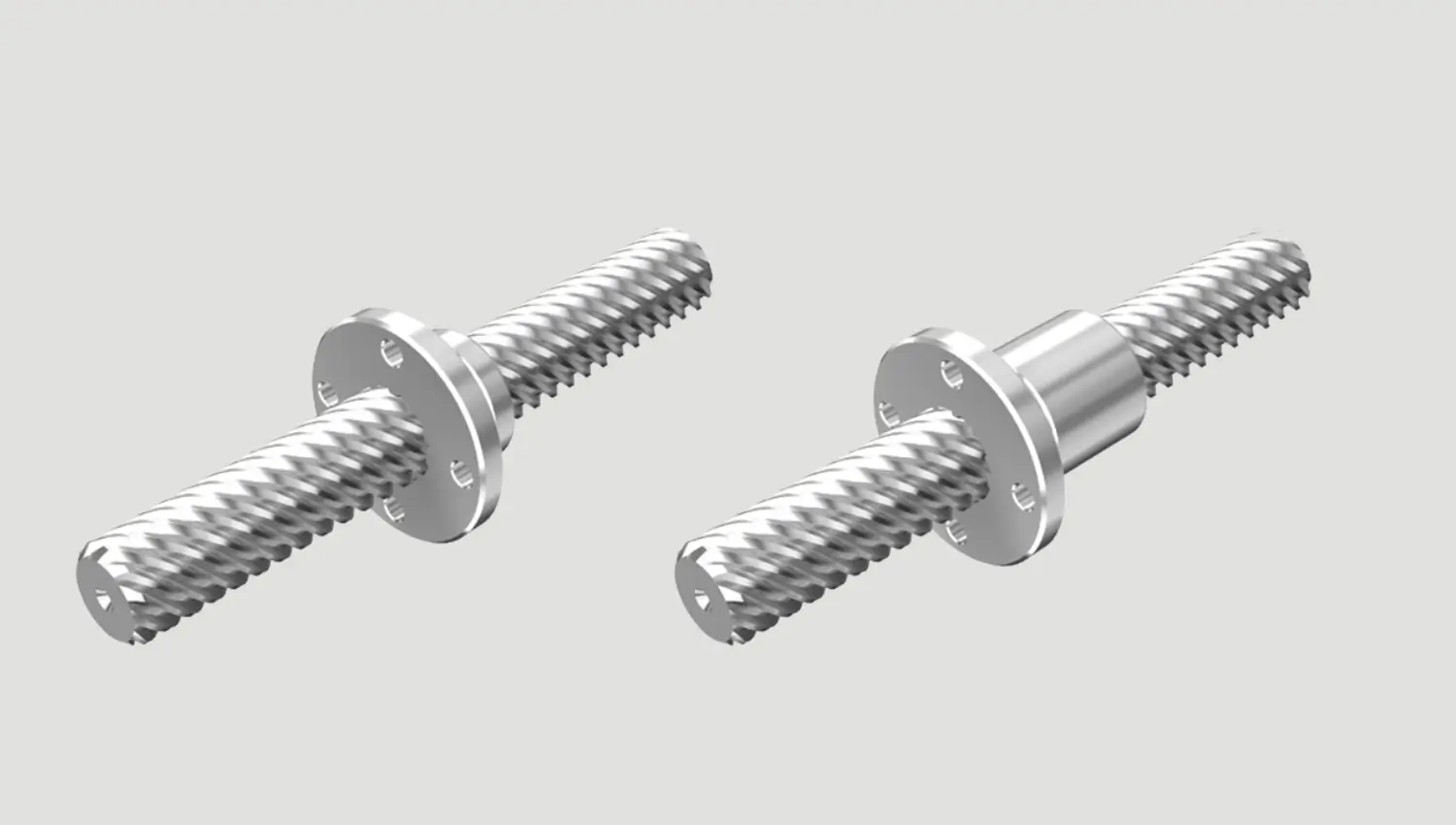

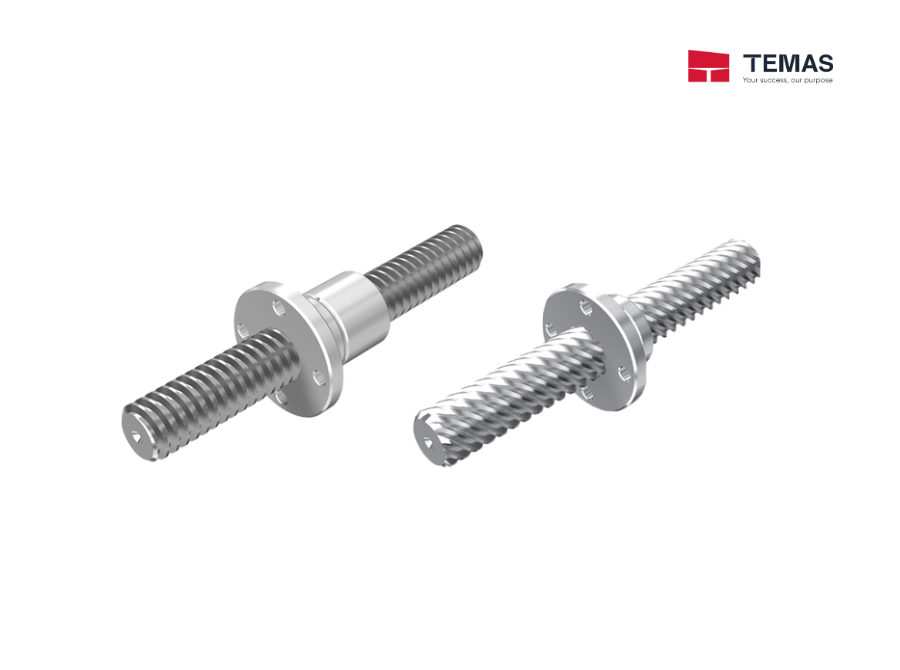

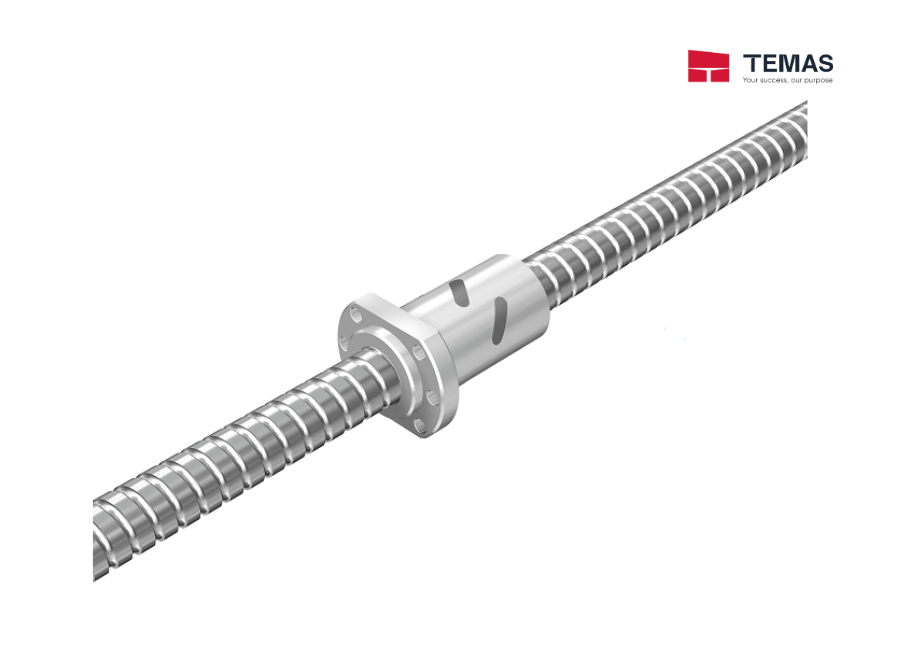

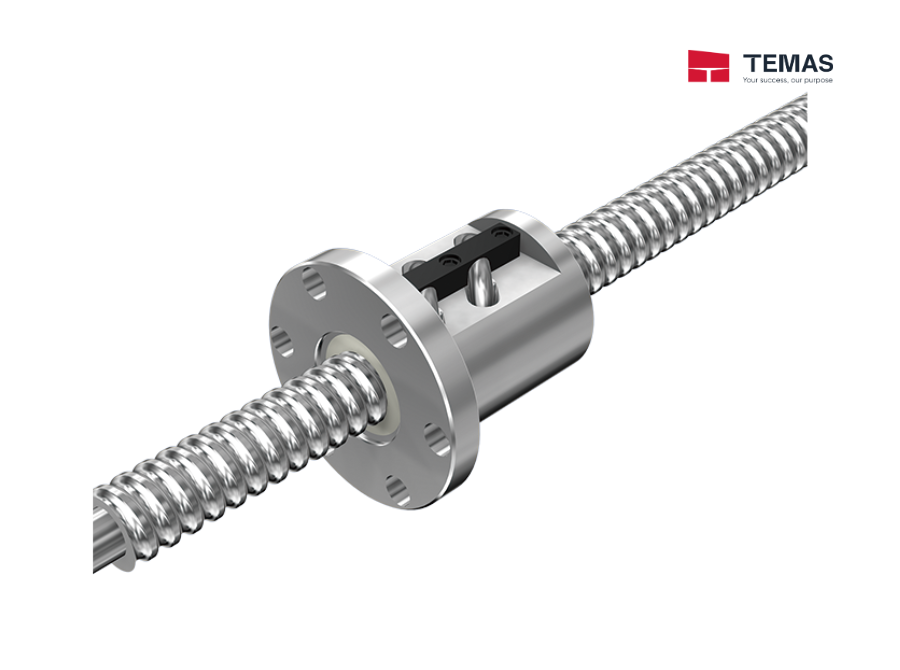

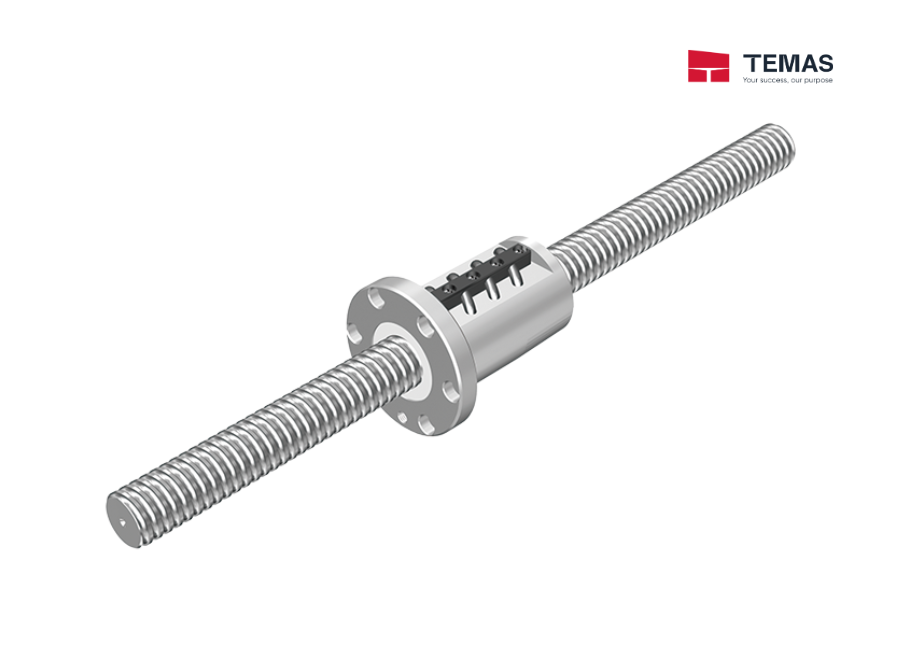

Types

Structure and Features

The Change Nut models DCMA and DCMB have a lead angle of 45°, which is diffi cult to achieve through machining. Each model is capable of converting a straight motion to a rotary motion, or a vise versa, at high efficiency. Because of the large leads, they are optimal for providing a fast feed mechanism at a lowspeed rotation. The multi-thread screw shafts to be combined with these change nuts are formed through cold gear rolling. The surface of the teeth is hardened to over 250 HV and mirror-finished. As a result, the shafts are highly wear resistant and achieve significantly smooth motion when used in combination with these change nuts.

Models DCMA40, DCMB40 or higher are designed for use in combination with the cut screw shafts. The Miniature Change Nuts are made of an oil-impregnated plastic, and have a wear resistance and excel in lubrication especially in an oil-less operation. In addition, since the high level of their performances can be maintained for a long period, they allow long-term maintenance-free operation.

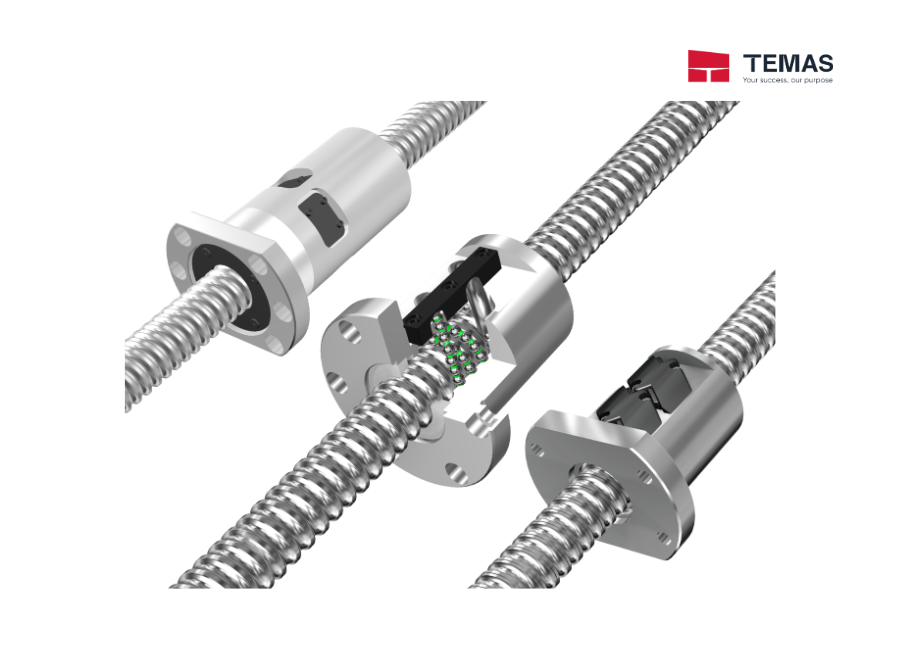

Features of the Special Rolled Shafts

Dedicated rolled shafts with the standardized lengths are available for the Change Nut.

Increased Wear Resistance

The shaft teeth are formed by cold gear rolling, and the tooth surface is hardened to over 250 HV and mirror-finished. As a result, the shafts are highly wear resistant and achieve significantly smooth motion when used in combination with the nuts.

Improved Mechanical Properties

Inside the teeth of the rolled shaft, a fi ber fl ow occurs along the contour of the tooth surface of the shaft, making the structure around the teeth roots dense. As a result, the fatigue strength is increased.

Additional Machining of the Shaft End Support

Since each shaft is rolled, additional machining of the support bearing of the shaft end can easily be performed by lathing or milling.

High Strength Zinc Alloy

The high strength zinc alloy used in the change nuts is a material that is highly resistant to seizure and the wear and has a high load carrying capacity. Information on mechanical properties, physical properties, and wear resistance is presented below.

*The figures shown are target values—these figures are not guaranteed.

Mechanical Properties

|

Item

|

Description

|

| Tensile strength |

275 N/mm2 to 314 N/mm2 |

| Tensile yield strength (0.2%) |

216 N/mm2 to 245 N/mm2 |

| Compressive strength |

539 N/mm2 to 686 N/mm2 |

| Compressive yield strength (0.2%) |

294 N/mm2 to 343 N/mm2 |

| Fatigue strength |

132 N/mm2×107(Schenk bending test) |

| Charpy impact |

0.098 N・m/mm2 to 0.49 N・m/mm2 |

| Elongation |

1 % to 5 % |

| Hardness |

120 HV to 145 HV |

Physical Properties

|

Item

|

Description

|

| Specific gravity |

6.8 |

| Specific heat |

460 J/(kg・K) |

| Melting point |

390 ℃ |

| Thermal expansion coefficient |

24×10-6 |

Wear Resistance

Table 3 [Test conditions: Amsler wear-tester]

|

Item

|

Description

|

| Test piece rotational speed |

185 min-1 |

| Load |

392 N |

| Lubricant |

Dynamo oil |