Technical Information

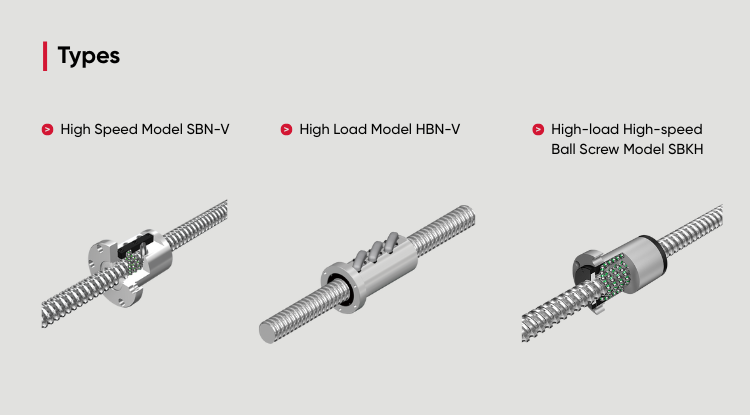

Types

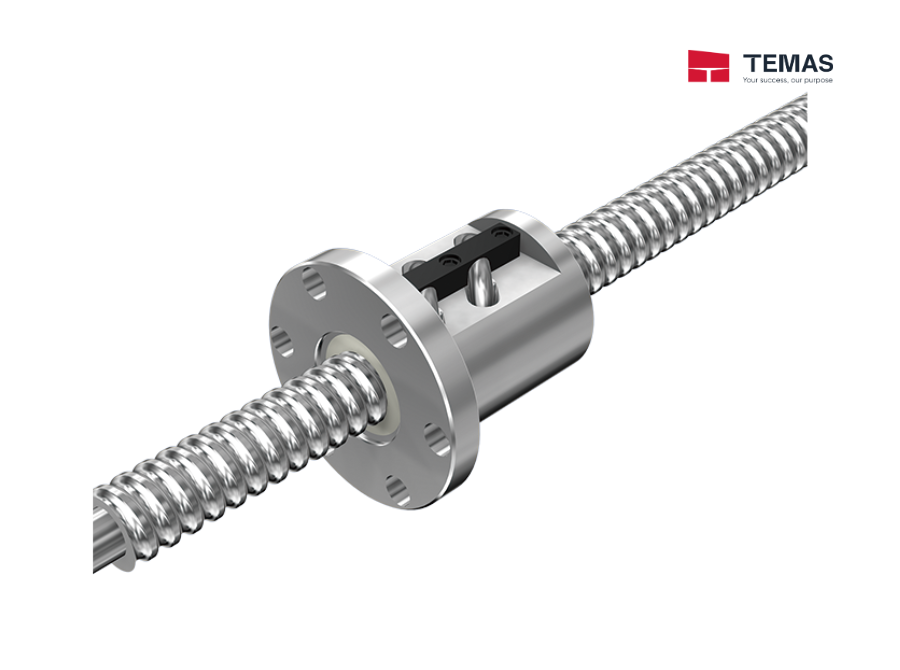

- High Speed Model SBN-V

- Model SBK

- High Speed Model SBKN

- High Load Model HBN-V

- High Load Model HBN-K/Model HBN-KA

- High Load Model HBN

- High-Load Ball Screw for Presses Model HBN-KP

- High-load High-speed Ball Screw Model SBKH

Features

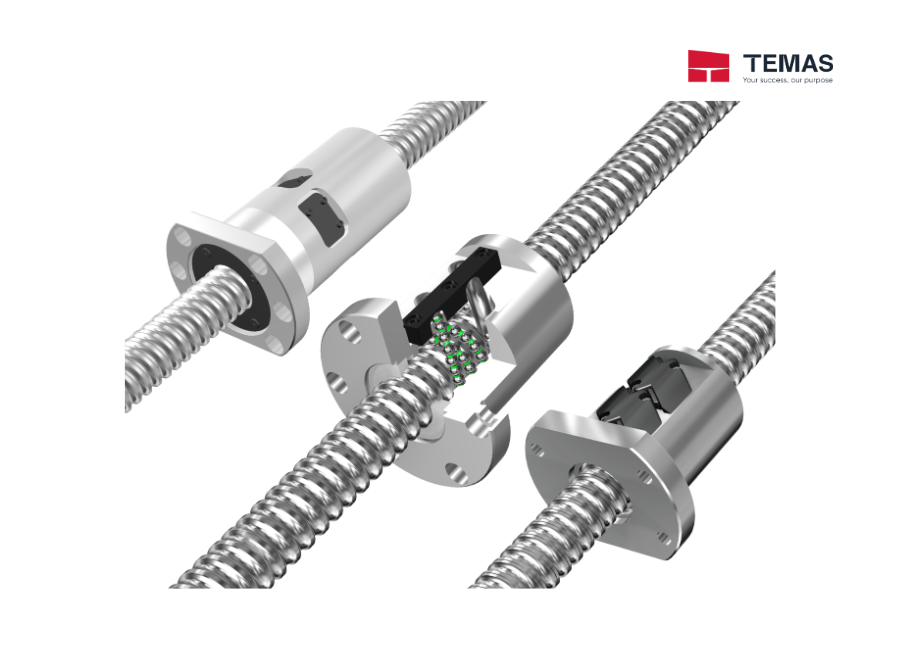

Structure and Features

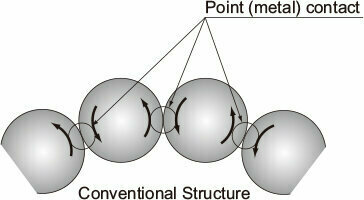

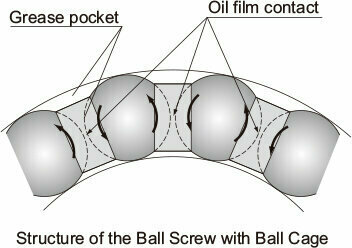

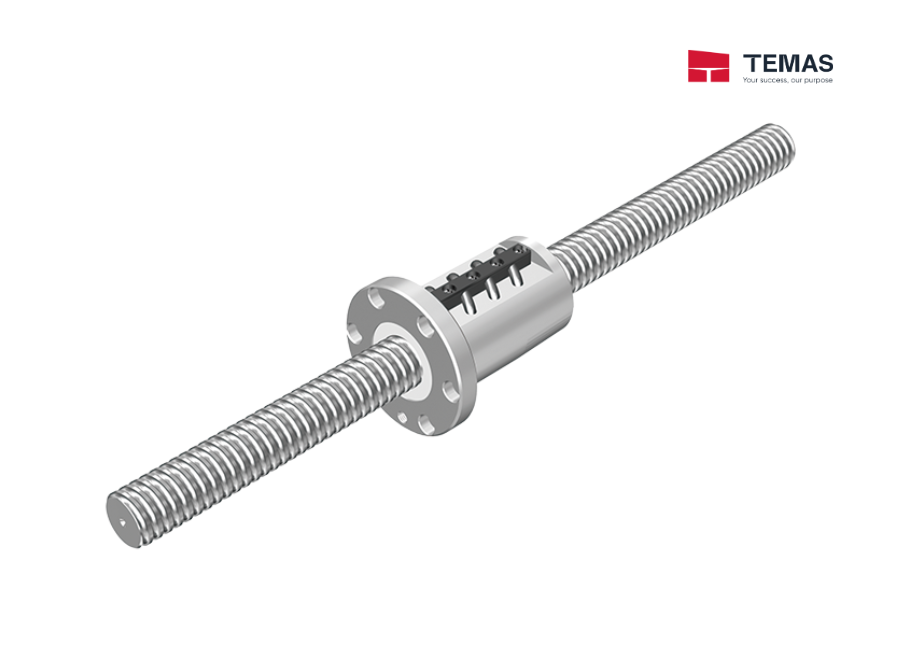

The use of a ball cage in the caged ball screw eliminates collision and friction between balls and increases grease retention. This makes it possible to achieve low noise, low torque fluctuation, and long-term maintenance-free operation.

In addition, this ball screw excels in high-speed applications because of an ideal ball recirculation structure, a strengthened circulation path, and the use of a ball cage.

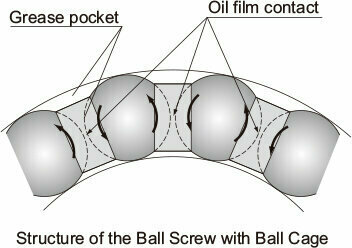

Ball Cage Effect

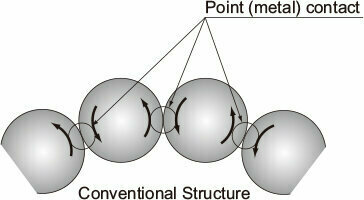

A. Low noise/reduced running sound

The use of the ball cage eliminates the collision noise between the balls. Additionally, as balls are picked up in the tangential direction, the collision noise from the ball circulation has also been eliminated.

|

|

B. Long-term maintenance-free operation

The friction between balls has been eliminated, and grease retention has been improved through the provision of grease pockets. As a result, long-term maintenance-free operation (i.e. long term operation without lubrication) is achieved.

|

C. Smooth Motion

The use of a ball cage eliminates the friction between balls and minimizes the torque fluctuation, thus allowing smooth motion to be achieved.

|

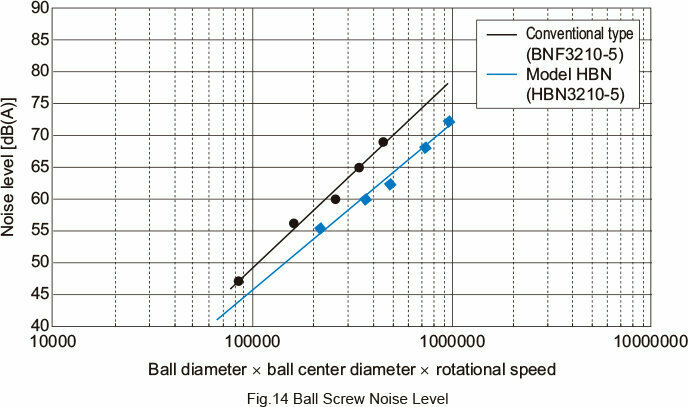

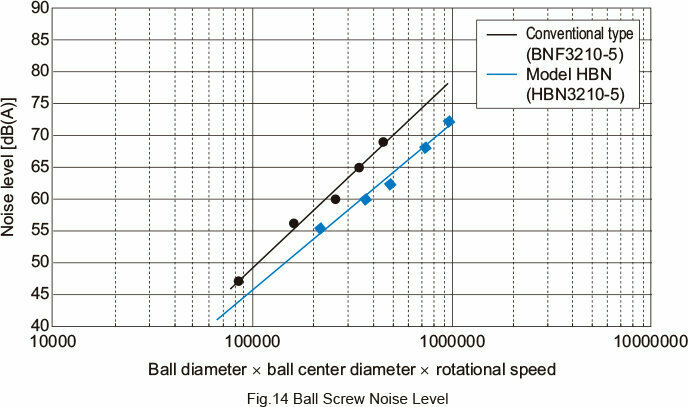

D. Low noise

● Noise Level Data

Since the balls in the caged ball screw do not collide with each other, they do not produce a metallic sound, and a low noise level is achieved.

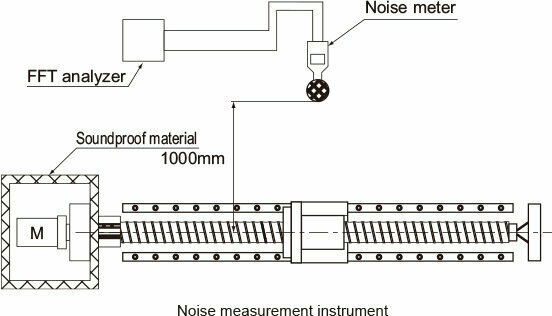

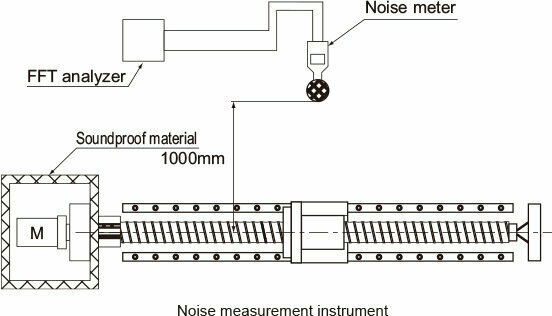

■ Noise Measurement

[Conditions]

| Item |

Description |

| Sample |

Caged ball screw HBN3210-5

Conventional Type: Model BNF3210-5

|

| Stroke |

600mm |

| Lubrication |

Grease lubrication (lithium-based grease containing extreme pressure agent) |

E. Long-term Maintenance-free Operation

● High speed and high load-bearing capacity

Thanks to the ball circulating method supporting high speed and the ball cage effect, the caged ball screw excels in high speed and load-bearing capacity.

■ High Speed Durability Test

[Test Conditions]

| Item |

Description |

| Sample |

High-Speed Caged Ball Screw

SDA3110V-5

|

| Speed |

5000 (min-1)(DN value*: 160,000) |

| Stroke |

500mm |

| Lubricant |

THK AFJ Grease |

| Quantity |

4 cm³ (lubricated every 500 km) |

| Applied Load |

1.27 kN |

| Acceleration |

0.5G |

*DN value: Ball center-to-center diameter x revolutions per minute

=> Test Results: Shows no deviation after running for 6000 km.

■ Load Bearing Test

[Test Conditions]

| Item |

Description |

| Sample |

High Speed Ball Screw with Ball Cage

SBN5016V-5

|

| Speed |

1500 (min-1)(DN value*: 79,000) |

| Stroke |

400mm |

| Lubricant |

THK AFG Grease |

| Quantity |

57.7 cm³ (lubricated every 100 km) |

| Applied load |

36.1 kN (0.38Ca) |

| Acceleration |

0.5G |

=> Test result: Shows no deviation after running for the calculated service life.

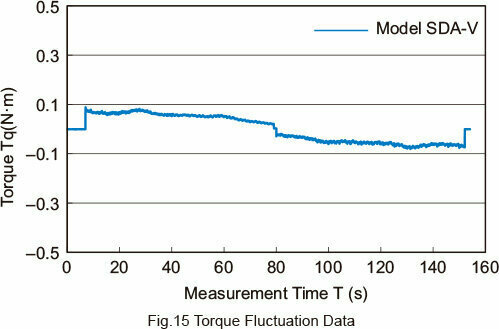

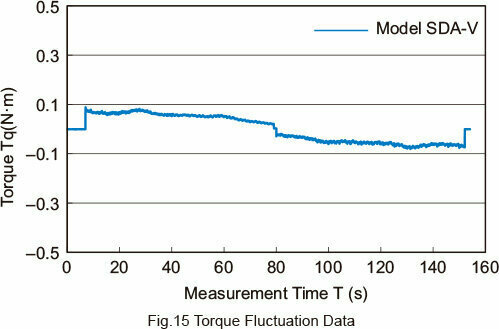

F. Smooth Motion

● Low Torque Fluctuation

The caged ball effect allows smoother motion than the conventional type to be achieved, thus reducing torque fluctuation.

[Conditions]

| Item |

Description |

| Shaft diameter/lead |

25/5mm |

| Shaft rotational speed |

100min-1 |

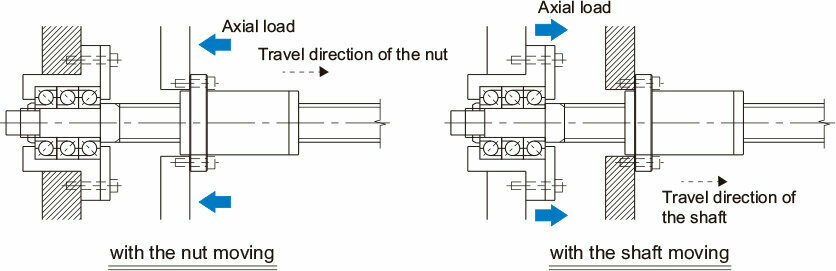

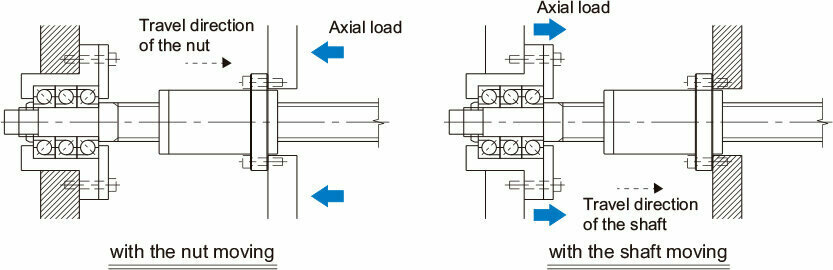

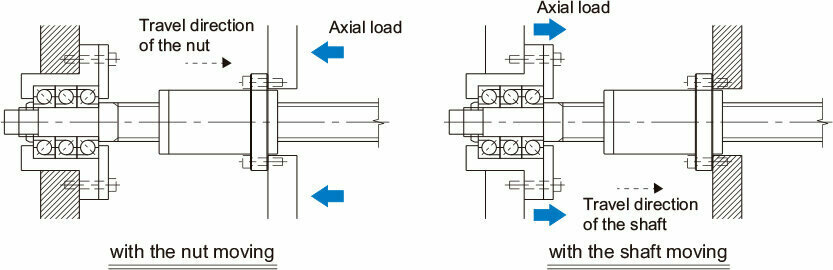

Examples of Assembling Models HBN-V, HBN-K, HBN-KA, HBN, and SBKH

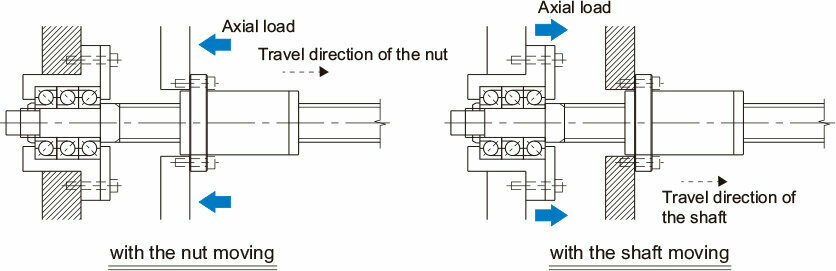

If using models HBN-V, HBN-K, HBN-KA, HBN, or SBKH under a large load, arrange the nut flange and the fixed-side support unit in relation to the loading direction as indicated in the figures below, while taking into account the load balance of the balls. In addition, be sure not to apply a tensile load to the bolts while the unit is operating. If you intend to use this product in configurations other than those below, contact Temas.

Example Assembly of Models HBN-V, HBN-K, HBN-KA, HBN, and SBKH (Recommended)

Example Assembly of Models HBN-V, HBN-K, HBN-KA, HBN, and SBKH (Not Recommended)