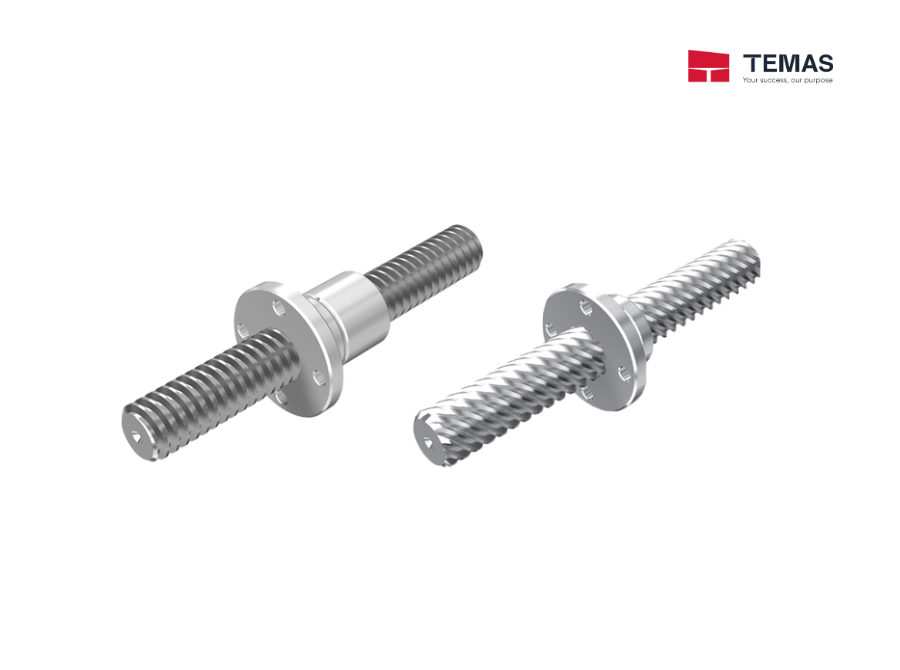

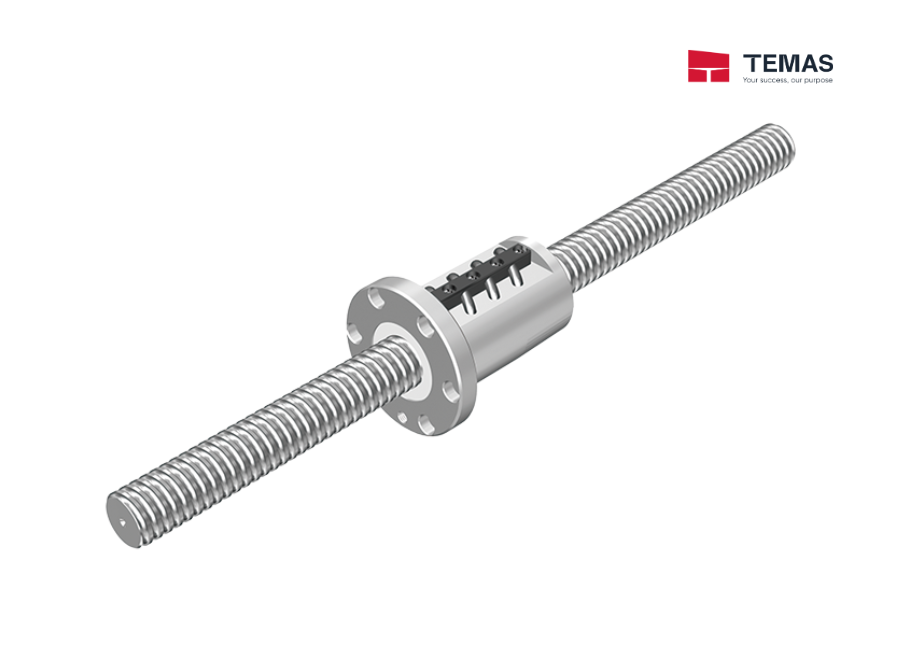

It is a high-precision, low-cost product die-cast from a special alloy for bearings with excellent wear resistance.

Schedule a maintenance appointment

SUBSCRIBE TO RECEIVE MONTHLY NEWSLETTER

We're committed to your privacy. Temas uses the information you provide to us to contact you about our relevant content, products, and services. You may unsubscribe from these communications at any time. For more information, check out our privacy policy.