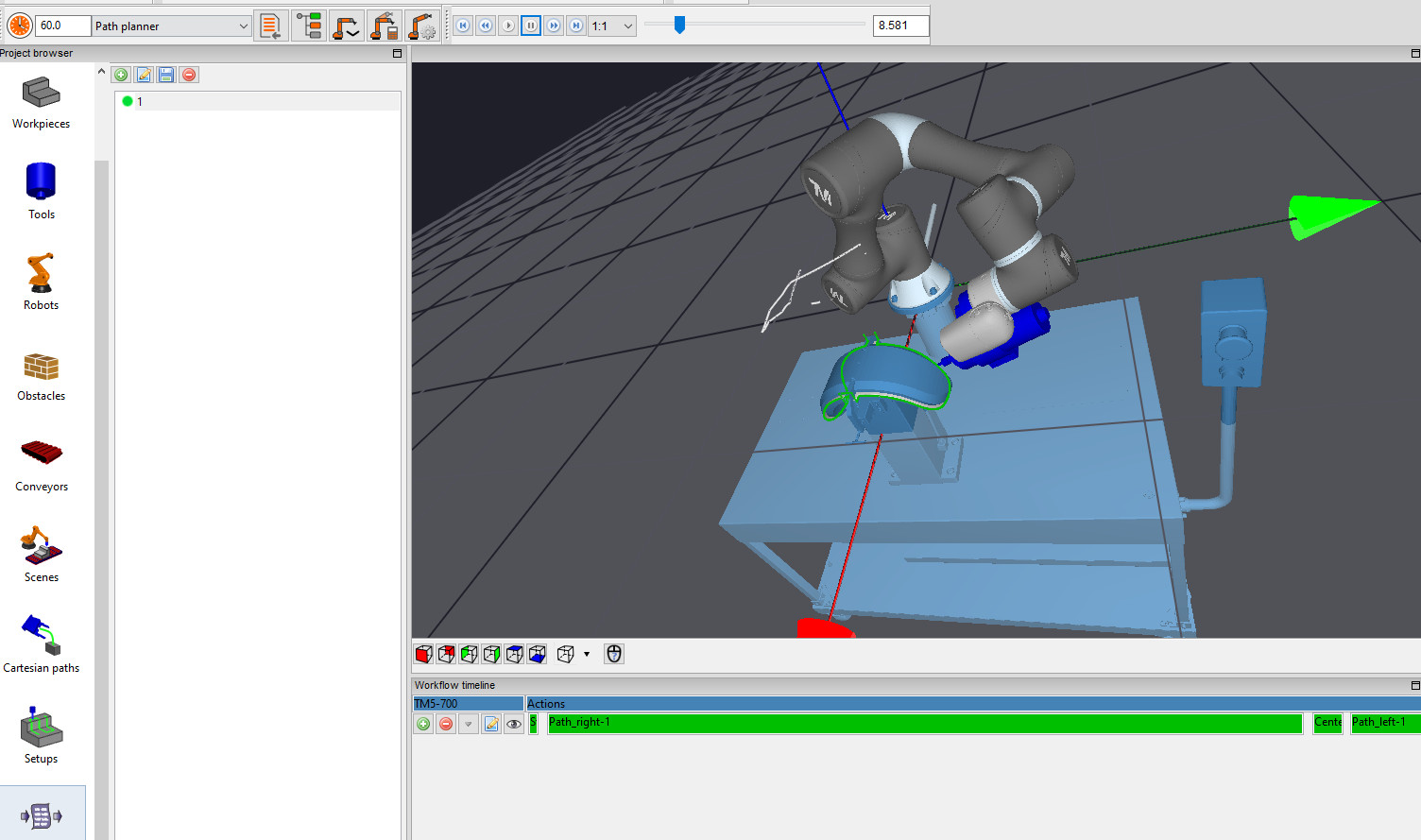

Generate robot programs automatically in real-time within seconds - up to 1000 times faster than traditionally.

.jpg)

| Approach | Supported processes |

|

|