Factories are always in pursuit of better productivity and quality. However, while managers strive for higher goals, they cannot overlook the risk and extra workloads that might be imposed on their workers. How can factories increase their performance while not sacrificing the quality of life and health of their workers? Techman robot provides a solution.

Tung Pei Industrial Co. is a Taiwanese manufacturer that produces industrial precision roller bearings, that are sold under the brand name TPI. In the packaging stage of production, the factory used to have human workers load the packed bearings into the cardboard box. Since the packed bearings are very heavy, the packaging process creates great loading that will accumulate and do harm to workers’ forearms. Fortunately, Techman robot provided a solution that not only reduced physical loading but also enhanced productivity and utility rate.

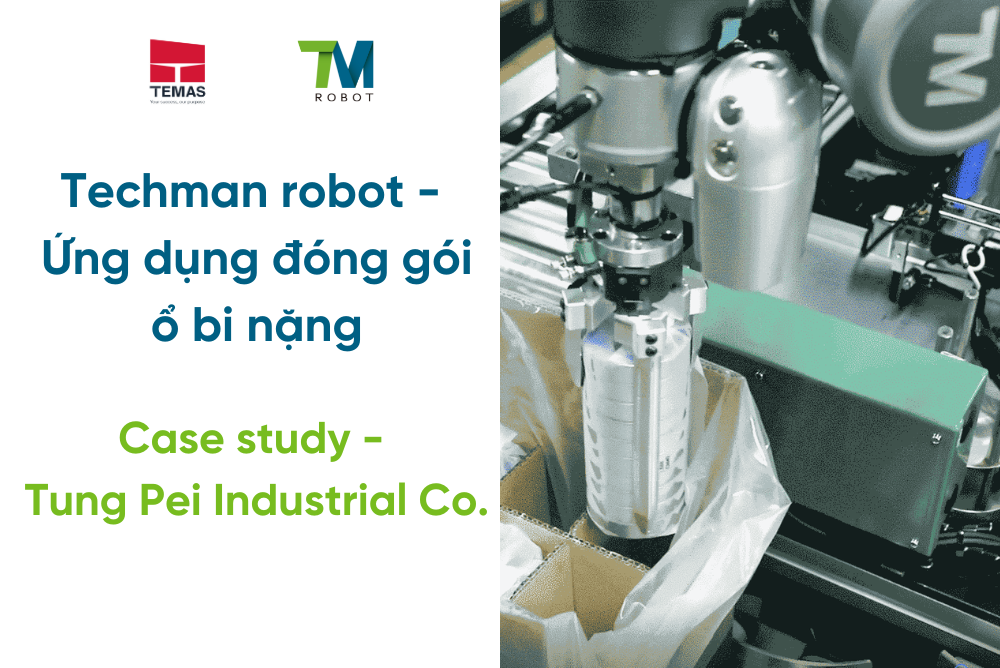

Leave the Heavy Parts to Cobot Arm

The section manager of Automatizing Scheme Department, Chia-Chin Chen, stated that the most significant benefit of introducing Techman robot was the reduction of workers' physical loading. The dividers inside the cardboard boxes have tolerance issues and are also placed somewhat tilted. If using a 4-axis arm to place bearings inside the box, it can only perform straight up and down movements. But with Techman’s 6-axis robotic arm, it can imitate human movement and tilt its arm in order to place the bearings in to each divider. This feature not only reduced physical loading but also saved time and improved efficiency.

TM Robot determining the correct angle to insert the bearings into the box

With the help of the cobot arm, workers no longer need to carry heavy parts, which greatly reduces the risk of injury. The Techman robot was designed with the consideration of imitating the movement of human arms, allowing it to hold and move heavy parts with ease. The robot can continue to work for hours without getting tired or asking for a break. This not only reduces the physical loading of the workers but also ensures the consistency and accuracy of the work.

Using Embedded Vision to Enhance Utilization Rate

Besides reducing physical loading, Techman robot is also assigned the task of reading the barcode on each box, which enhances the utility rate of the production line. "We have multiple kinds of cardboard boxes on one production line. Each box have a different barcode. When we designed the automation process, we want to use TM Robot’s built-in vision system. It can easily identify whether the box is the correct one for packing.” says Zhong-Xiang Yang, TPI production line engineer. This feature not only reduces potential human errors but also frees up workers to focus on other tasks, thereby improving the productivity of the entire line.

TM Robot scanning the barcode on the box with its embedded vision

The embedded vision technology of Techman robot greatly improves the accuracy and efficiency of the production line. With the ability to read barcodes, the robot can determine the packaging way of the boxes on its own, greatly reducing the chances of human errors. This ensures that the production line runs smoothly and efficiently, without any delays or mistakes. The workers can focus on other tasks, which not only improves the productivity of the entire line but also allows them to develop and apply their skills in more areas.

Overall Benefits

The implementation of Techman robot provides both workers and the enterprise a win-win result. Workers can now stay in a healthier condition and extend their potential career since their physical workload is reduced. The enterprise also benefits from happier workers and a better productivity production line. Techman robot's design and features allow it to increase productivity and efficiency while reducing physical strain on workers, making it an ideal solution for factories aiming for higher goals.

The implementation of Techman robot has brought significant benefits to Tung Pei Industrial Co. The physical workload of workers is greatly reduced, which not only protects their health but also allows them to develop more skills and apply them to other areas. The productivity and efficiency of the production line are improved, which ensures the consistency and accuracy of the work. The enterprise benefits from happier workers and a better production line, which greatly improves the overall performance of the company.

Techman robot's success story in Tung Pei Industrial Co. is an excellent example of how technology can benefit both workers and enterprises. The robot's ability to reduce physical loading, improve efficiency, and enhance utility rate makes it an ideal solution for factories. As more and more factories adopt Techman robot, we can expect to see more success stories like Tung Pei Industrial Co. With the help of technology, we can achieve higher performance while ensuring the quality of life and health of workers.

![MOON LIFTER - SUCCESS STORY OF ONCHI SHOKUHIN CO., LTD. [KYOTO]](https://temas.vn/filemanage/Case Stories/Unipulse/Moon Lifter/cau_chuyen_thanh_cong_moon_lifter_3.jpg)

Read more

Read more