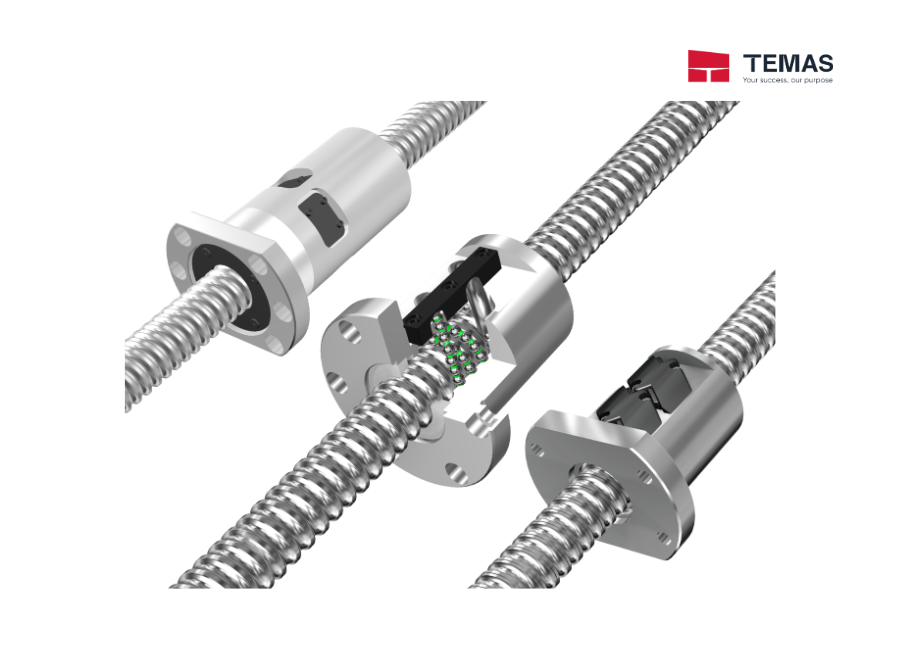

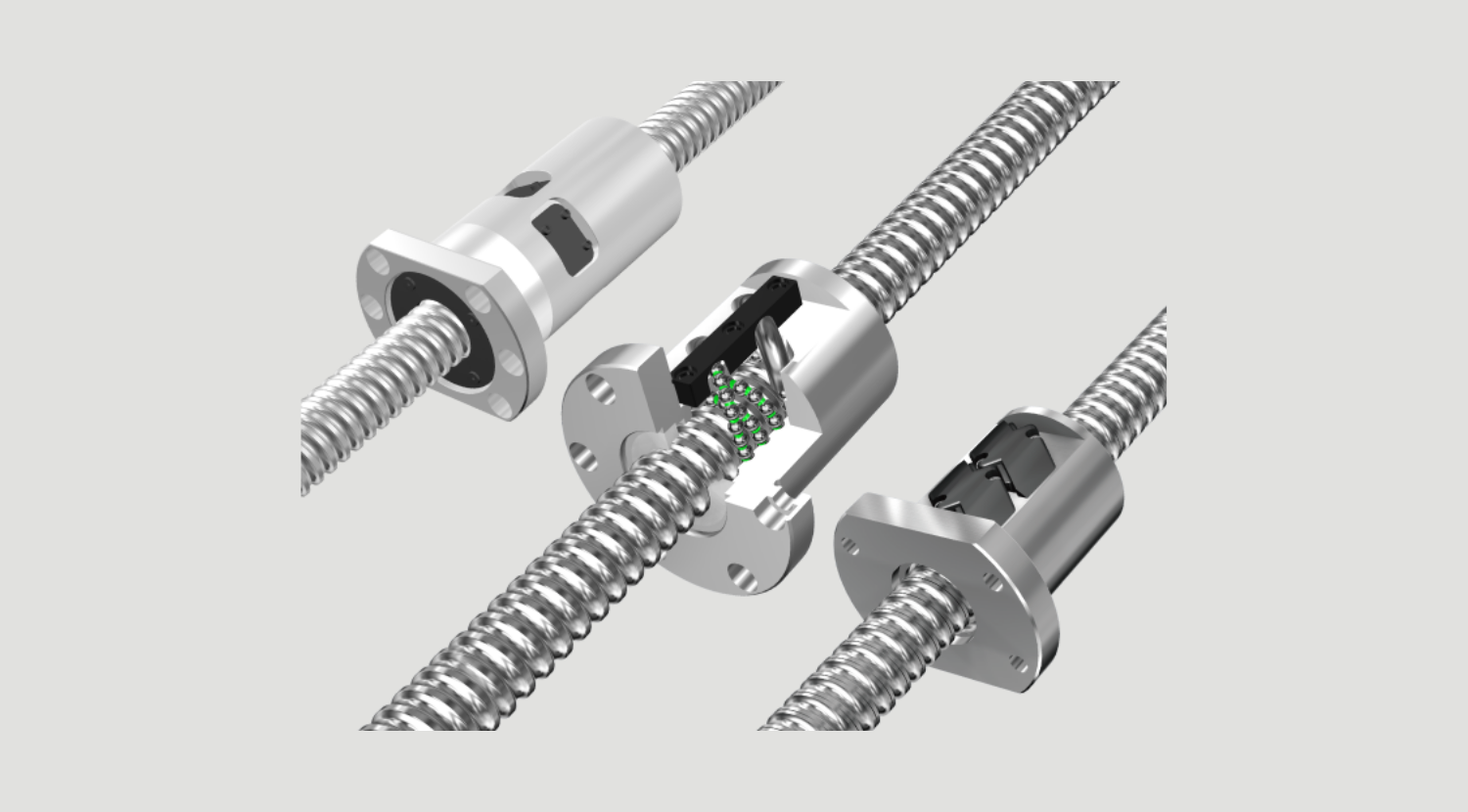

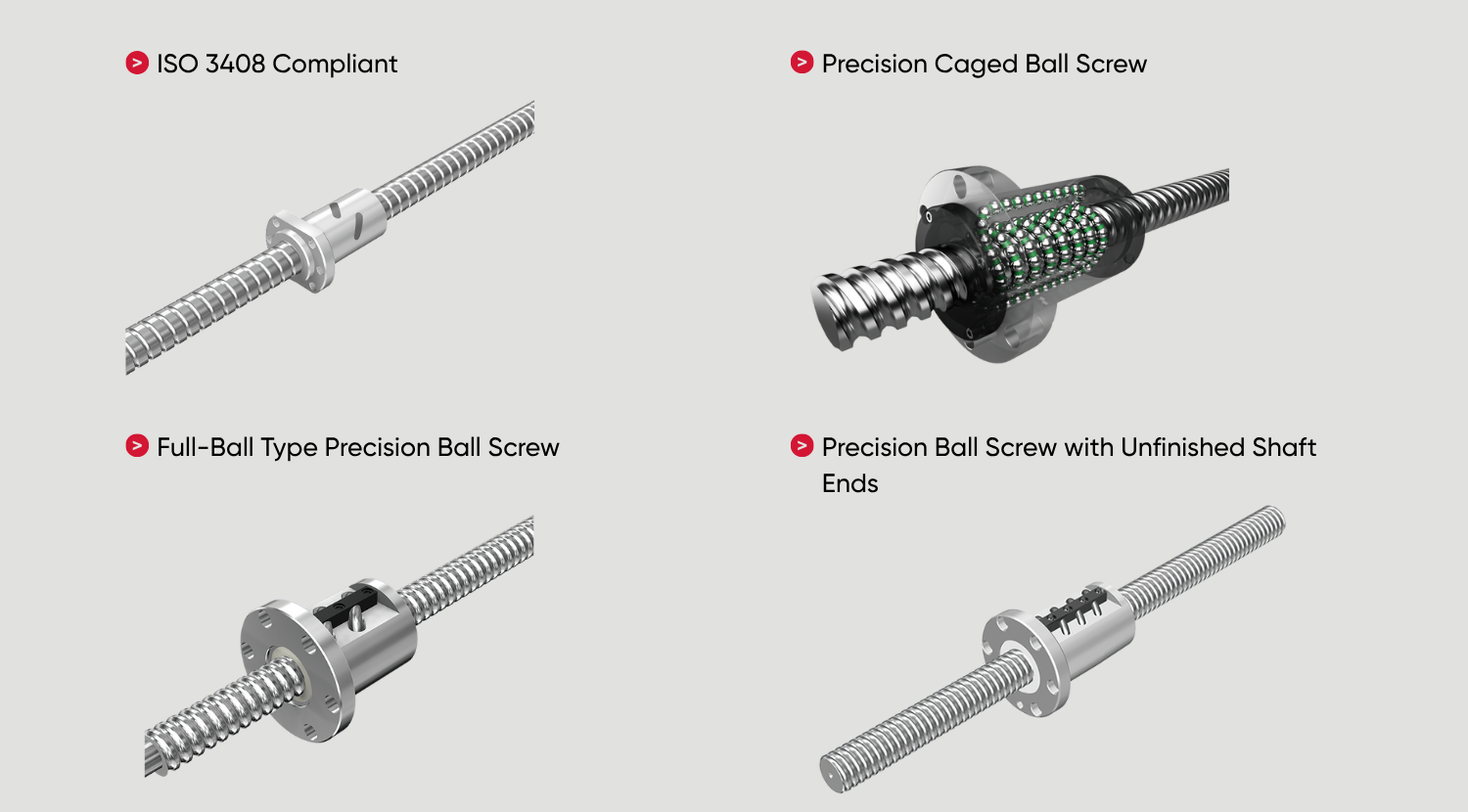

| ISO 3408 Compliant |

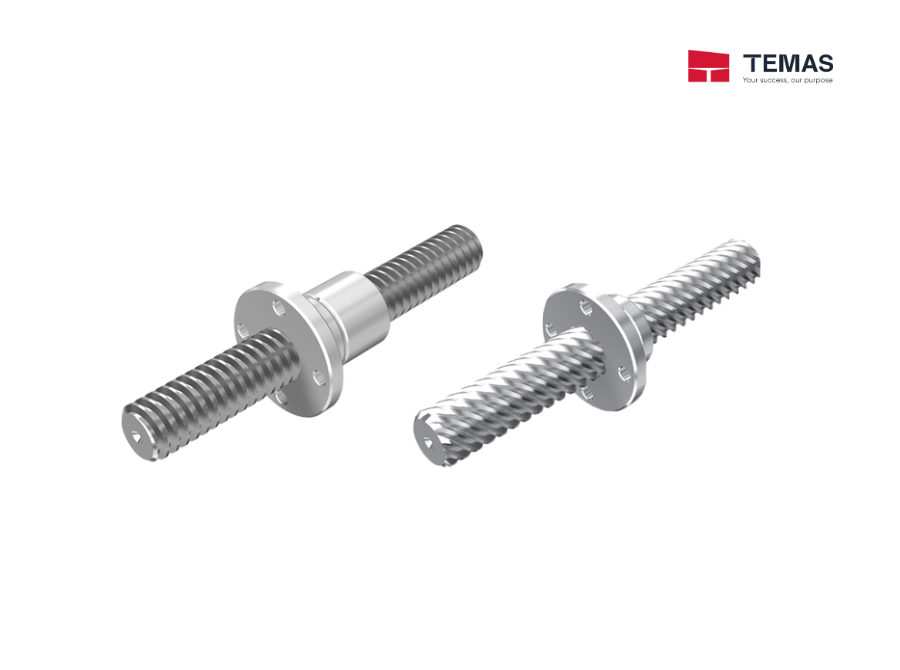

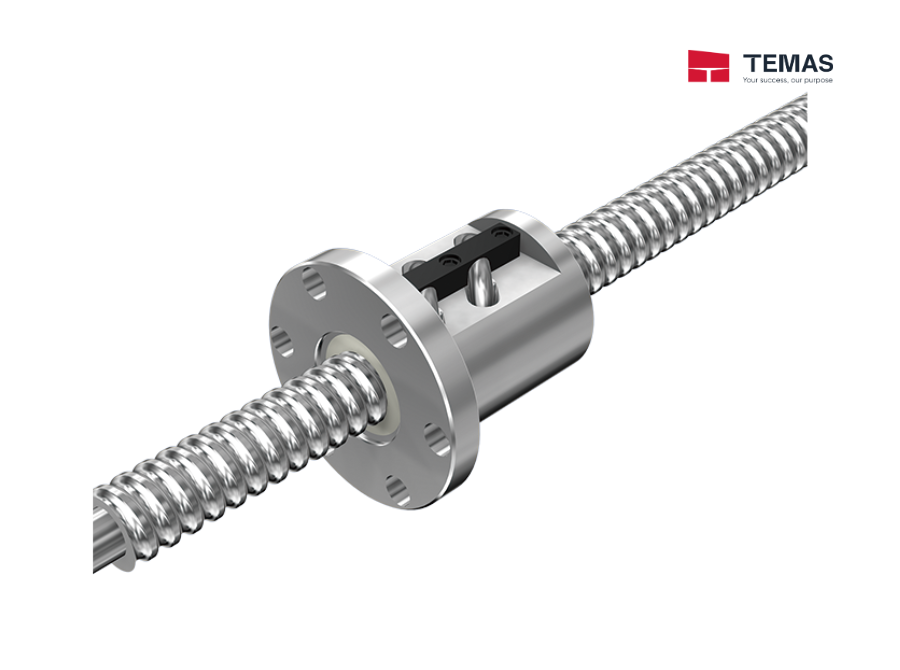

Precision Caged Ball Screw |

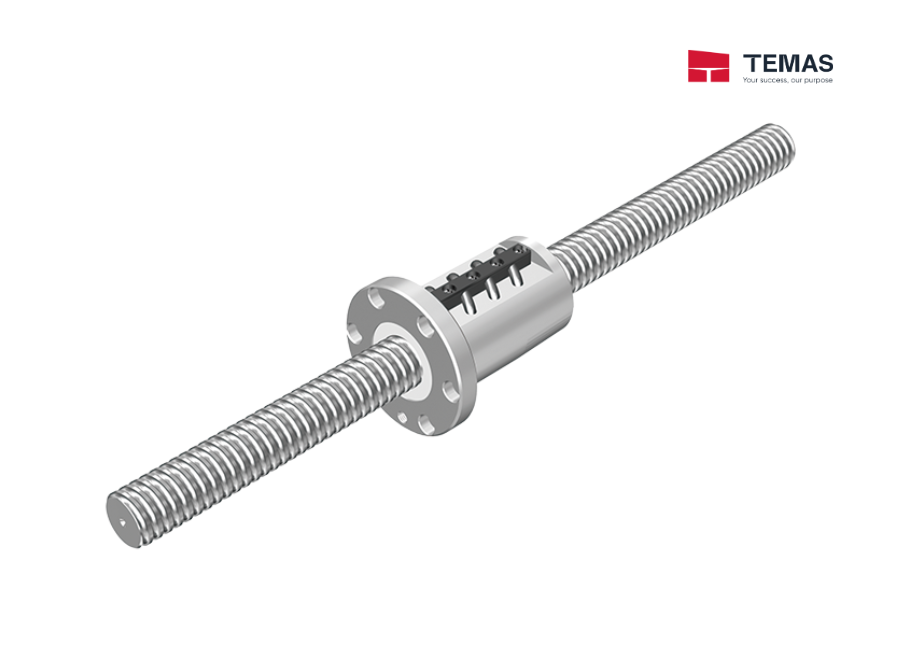

Full-Ball Type Precision Ball Screw |

|

|

|

| In the DIN standard compliant Ball Screw, balls under a load roll in the raceway cut between the screw shaft and the nut while receiving the axial load, travel along the groove of a deflector embedded inside the nut to the adjacent raceway, and then circulate back to the loaded area. Thus, the balls perform infinite rolling motion |

The ball cage enables this ball screw to have low noise, low torque fluctuation, and long-term maintenance-free operation. |

This type of ball screw is mass-produced by cutting the standardized screw shafts of precision ball screws to fixed lengths. Additional machining of the shaft ends can easily be performed. |

| Go to product page |

Go to product page |

Go to product page |

| Precision Ball Screw with Unfinished Shaft Ends |

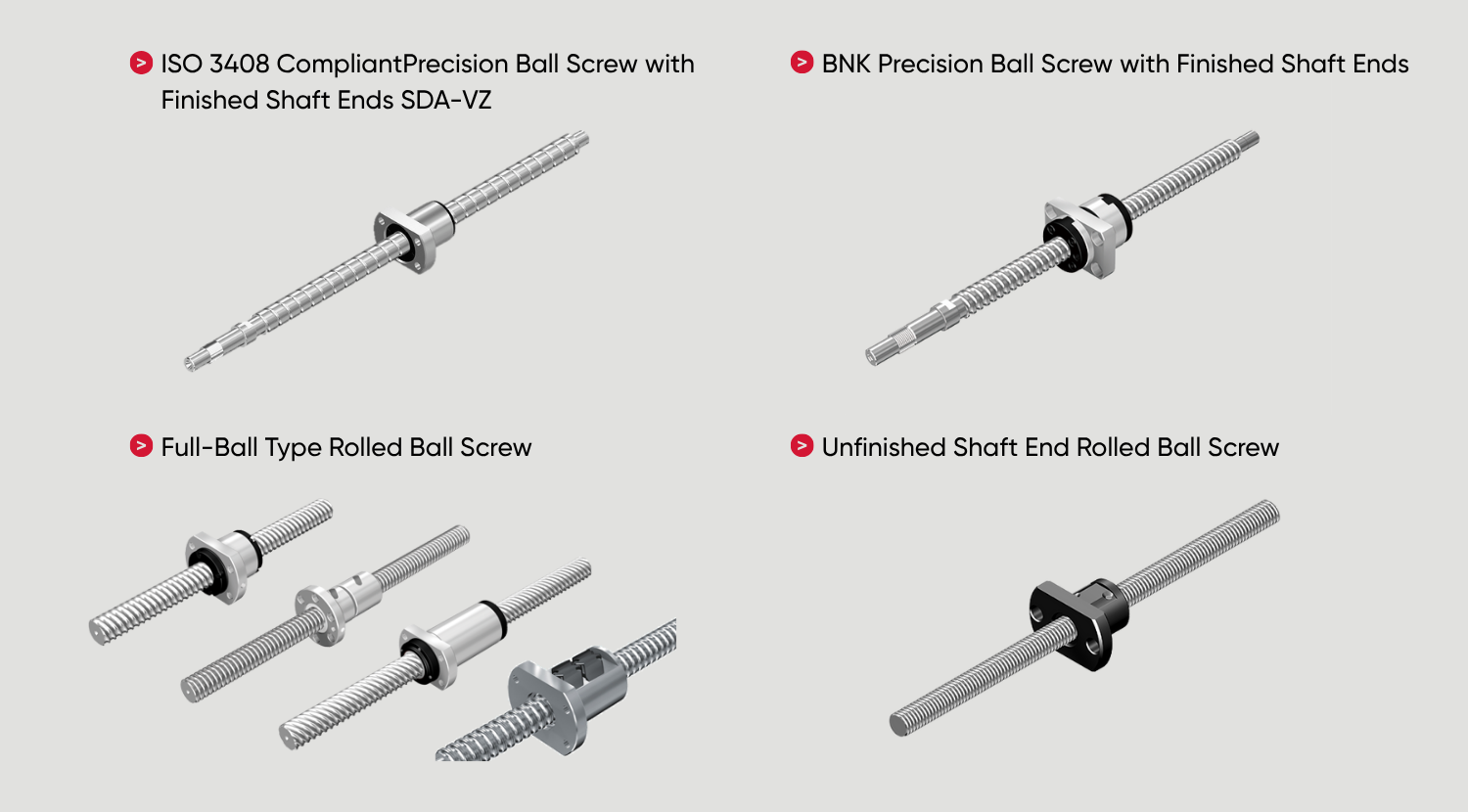

Precision Ball Screw with Finished Shaft Ends SDA-VZ |

BNK Precision Ball Screw with Finished Shaft Ends |

|

|

|

| This type of ball screw is mass-produced by cutting the standardized screw shafts of precision ball screws to fixed lengths. Additional machining of the shaft ends can easily be performed. |

These ball screw products are fabricated with standardized shaft end shapes. The Model SDA-VZ, which features a compact, ISO-compliant nut, has been added to the lineup.

These products can be used in combination with dedicated support units to make assembly design easy and significantly faster. |

The Model BNK is a ball screw with a finished shaft end machined to match the support unit. |

| Go to product page |

Go to product page |

Go to product page |

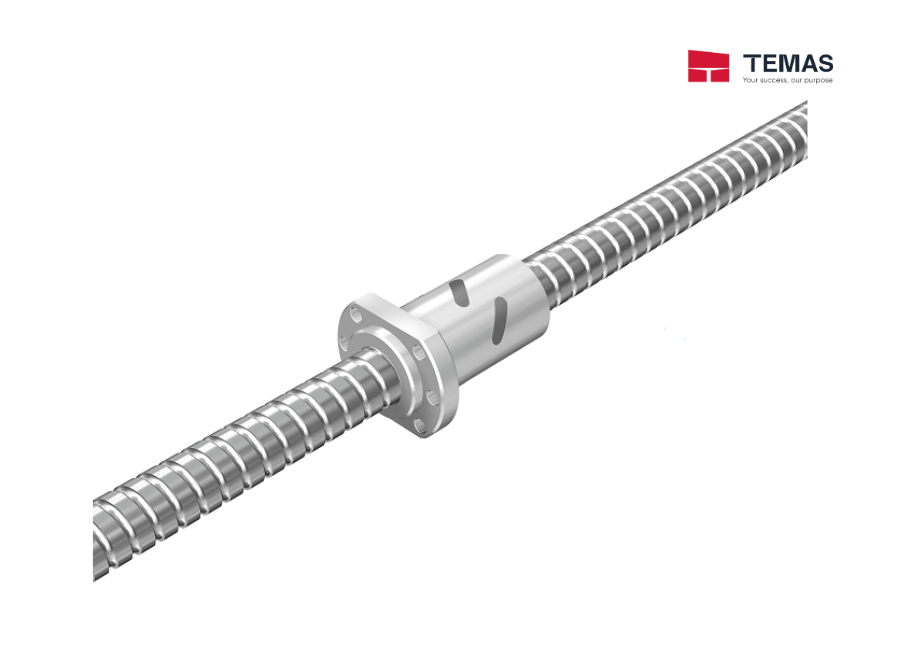

| Full-Ball Type Rolled Ball Screw |

Unfinished Shaft End Rolled Ball Screw |

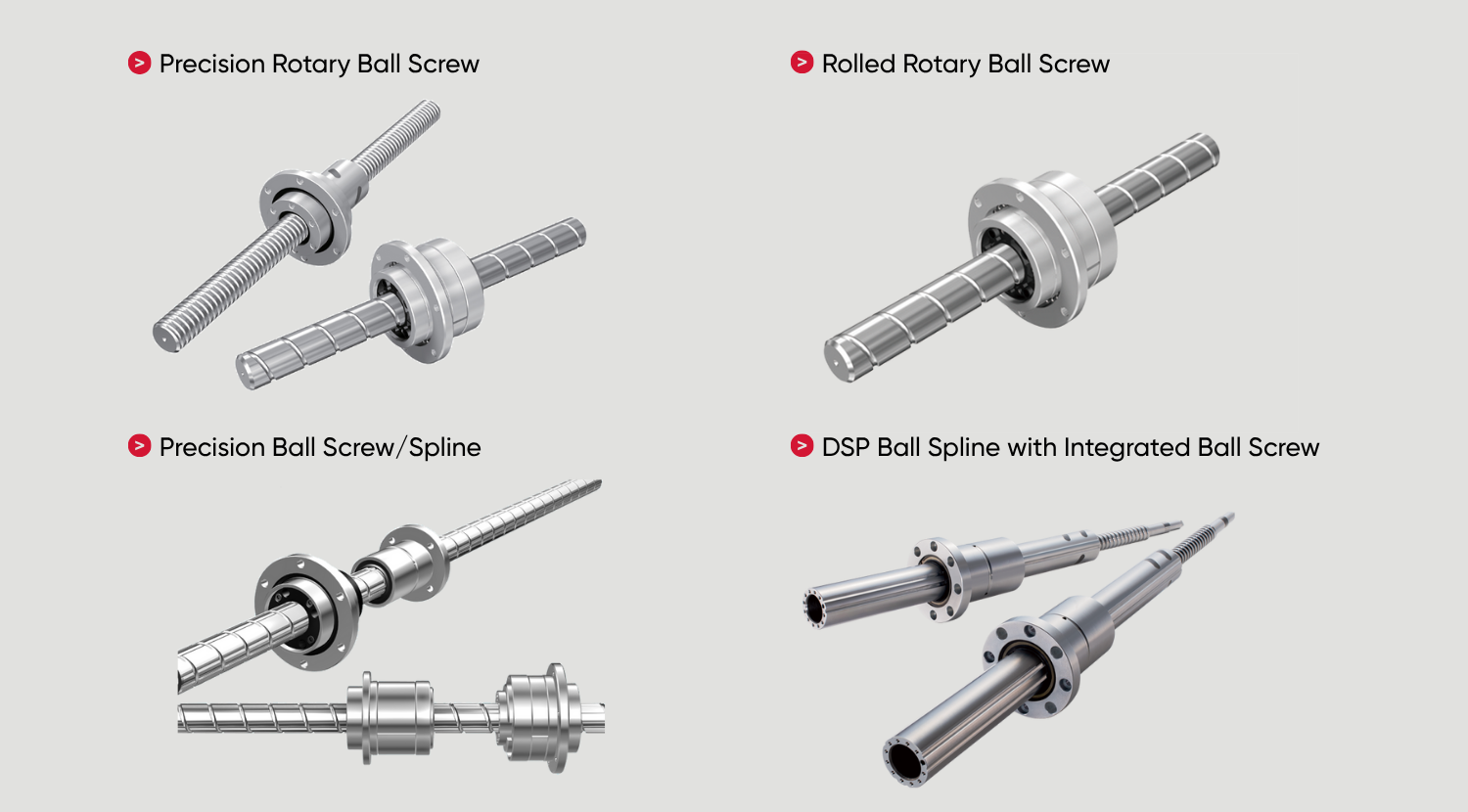

Precision Rotary Ball Screw |

|

|

|

| This ball screw uses a screw shaft rolled with high precision |

The use of a guide plate system provides a compact design with a round outer diameter for the nut. The screw shaft is roll-molded with a high degree of precision to ensure smooth operation. |

This is a rotary-nut ball screw that has an integrated structure consisting of a ball screw nut and a support bearing. |

| Go to product page |

Go to product page |

Go to product page |

| Rolled Rotary Ball Screw |

Precision Ball Screw/Spline |

DSP Ball Spline with Integrated Ball Screw |

|

|

|

| The rotary ball screw is a rotary-nut ball screw unit that has an integrated structure consisting of a ball screw nut and a support bearing. |

The ball screw grooves and the ball spline groove cross one another on a single shaft and the nuts of the ball screw and the ball spline have dedicated support bearings directly embedded on the circumference of the nuts. |

The DSP transmits a large thrust with smooth motion due to the integrated structure of the linear guide ball spline and the ball screw as the drive source. |

| Go to product page |

Go to product page |

Go to product page |

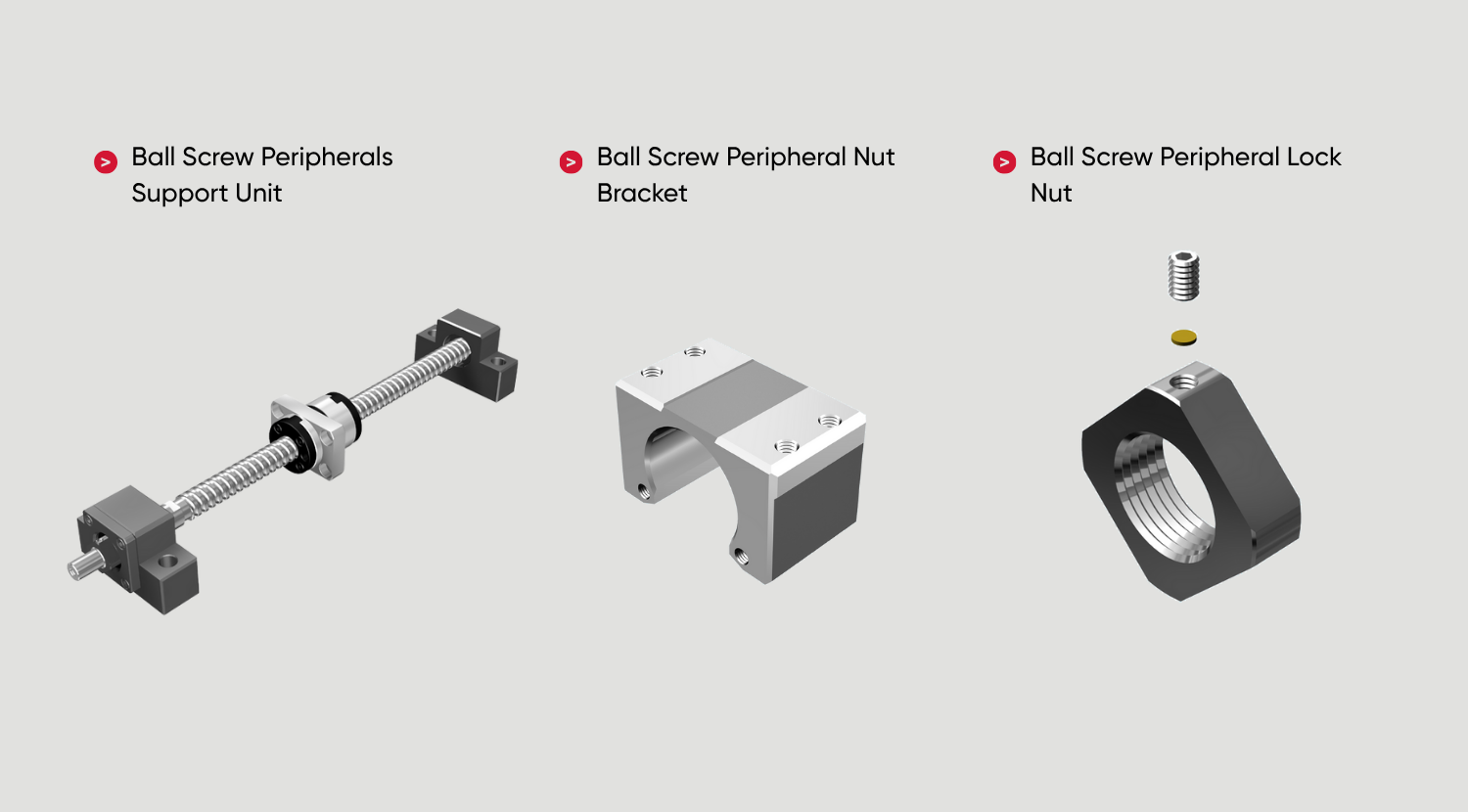

| Ball Screw Peripherals Support Unit |

Ball Screw Peripheral Nut Bracket |

Ball Screw Peripheral Lock Nut |

|

|

|

Support units are dedicated bearing components used as a set with ball screws.

They come in several types: models EK, FK, EF, and FF, which are tailored to fit Model BNK and Model SDA-VZ precision ball screws with finished shaft ends; models EK-L and EF-L, which are for low shaft centers; and models BK and BF, which are standardized for general ball screws.

The support unit on the fixed side includes a JIS Class 5-compliant angular bearing provided with an adjusted preload. The support unit on the supported side uses a deep-groove ball bearing. |

The nut bracket is standardized for the standard ball screw assembly provided with finished shaft ends. It is designed to be secured directly on the table with bolts. Since the height is low, it can be mounted on the table only using bolts. |

The Lock Nut for the Ball Screws is capable of fastening the screw shaft and the bearing with a high accuracy. The provided hexagonal socket-head setscrew and the set piece prevent the Lock Nut from loosening and ensure firm fastening. |

| Go to product page |

Go to product page |

Go to product page |