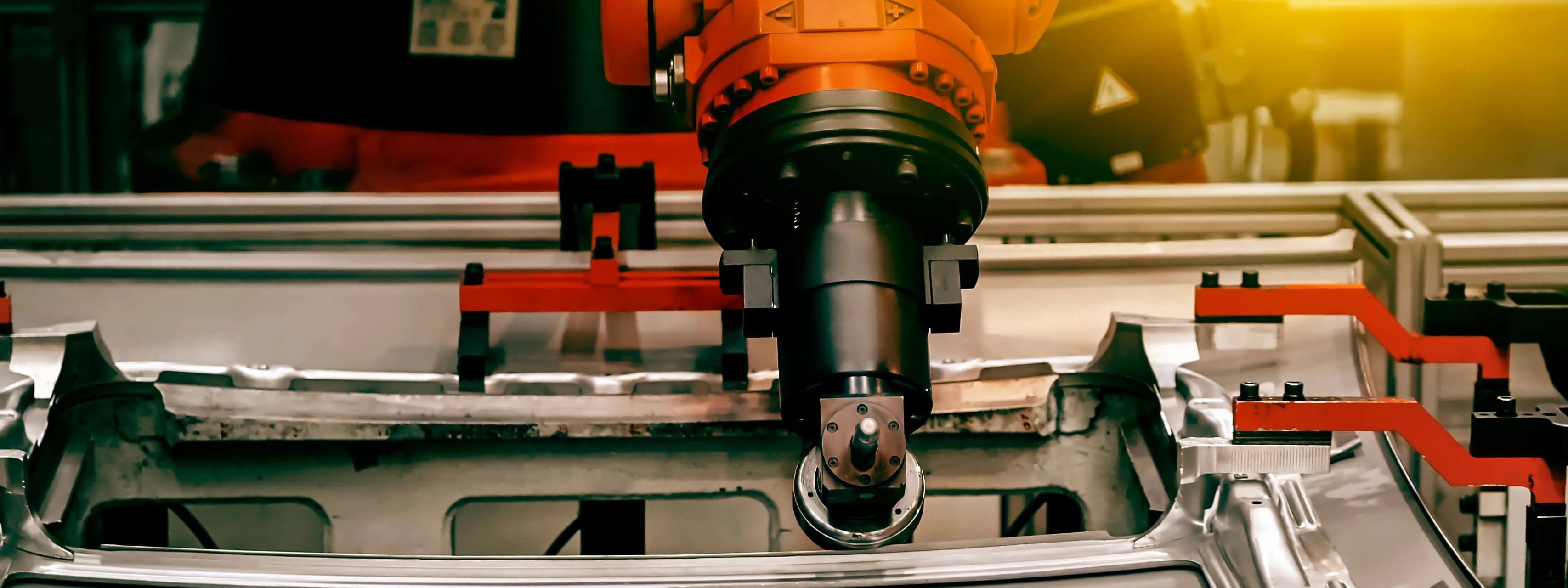

One of the final processes in machining is Grinding, which helps to remove redundancies and make the product in a fine shape. This product can be done with a special tool to help workers work on it, but also subordinate to work experience and the result can be difference on just one model of the product. To solve this problem we can integrate robot or Collaborative robot from TECHMAN and Grinding tools with force control (6 axes tool) in order to adjust robot movement to subtract any difference in the shape of designed workpieces, with advantages:

- Replace and compensate human work for the differential of experience, feelings, and prevent mistakes.

- Control force and adjust the movement of the robot in real-time when touching the workpiece even in a complex surface or curve.

- Monitor and fixed product position to help robot keep track on workpiece surface or curve.

- With complex 3D workpieces, software like Automappps can help fast create the program in 3D paths

Our technical team is capable, adaptive, experience, and well trained by our partners TECHMAN collaborative robot and Convergent-IT with stimulating software for the robot, grinding tools from Onrobot. We Temas are confident in integration, and always find out the ideal solution with a perfect price for your requirements.

Don't miss our latest blog posts and updates by registering to become a new member, or can connect directly with us via email and phone, we can help you to find out the solution for your need.