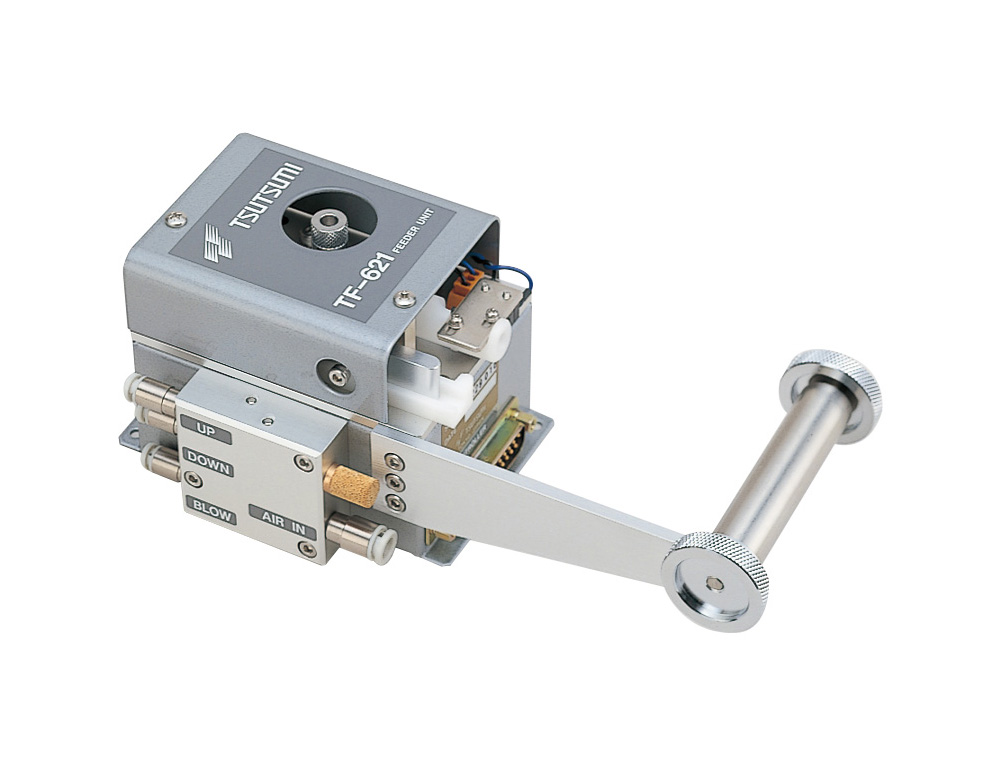

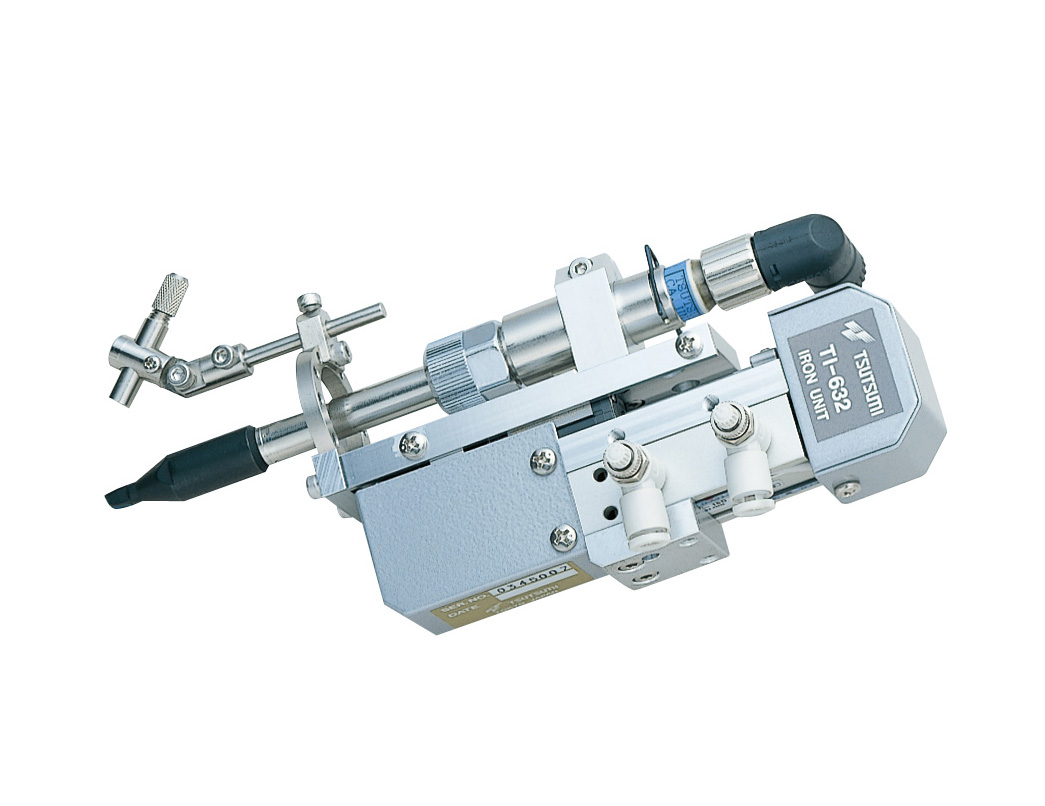

In the field of PCB production, the use of tin soldering machines has become familiar to us. Although most of the stages are performed by SMT machine systems, they cannot do all of them, such as when performing the soldering of large-sized components (capacitors, connectors,...) or when soldering cables to the circuit board, ... requires us to use workers and solder tips in these cases.

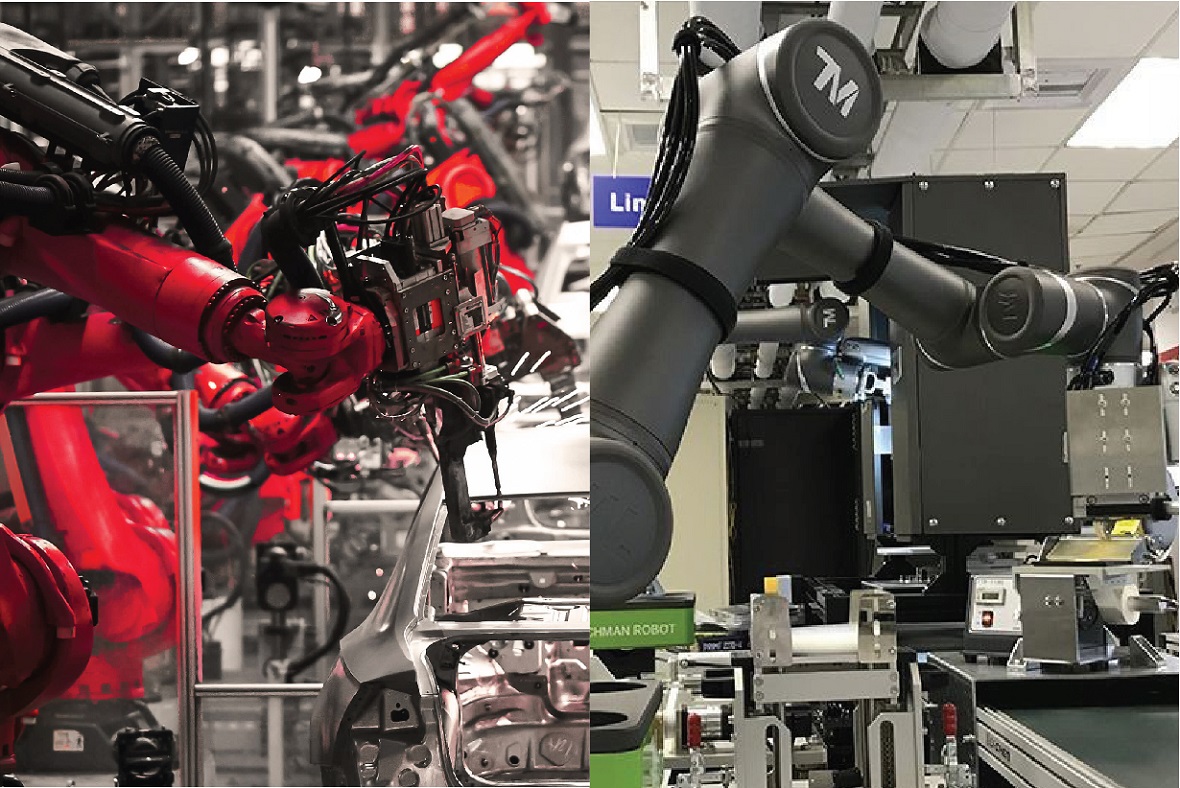

Today, with electronics factories massively investing in Vietnam, the amount of labor has also become scarce, while the requirements for performance and quality stability are increasing, the solution using soldering robot is a trend. With its outstanding advantages, we can easily convert and upgrade from a manual welding solution with a welding tip to a robot:

- Easy to access because the method of heat sealing is similar to the manual method.

- Easy to maintain, replace and repair.

- Easy program setup.

- Control soldering temperature, help save solder wire and control solder quality.

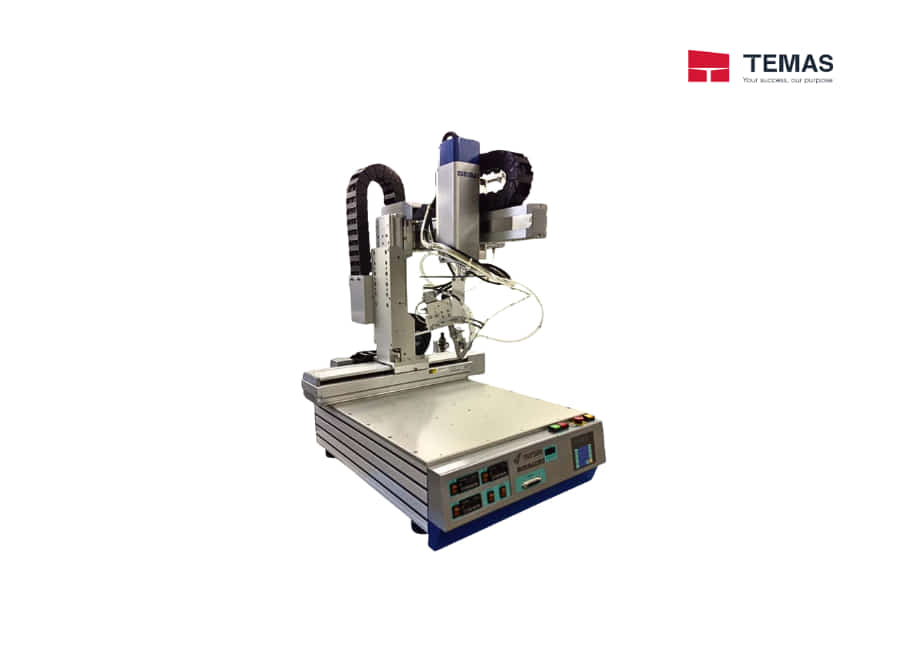

- Suitable for semi-automatic soldering or fully automatic system integration.

- Reasonable price and bring stability, high performance in production.

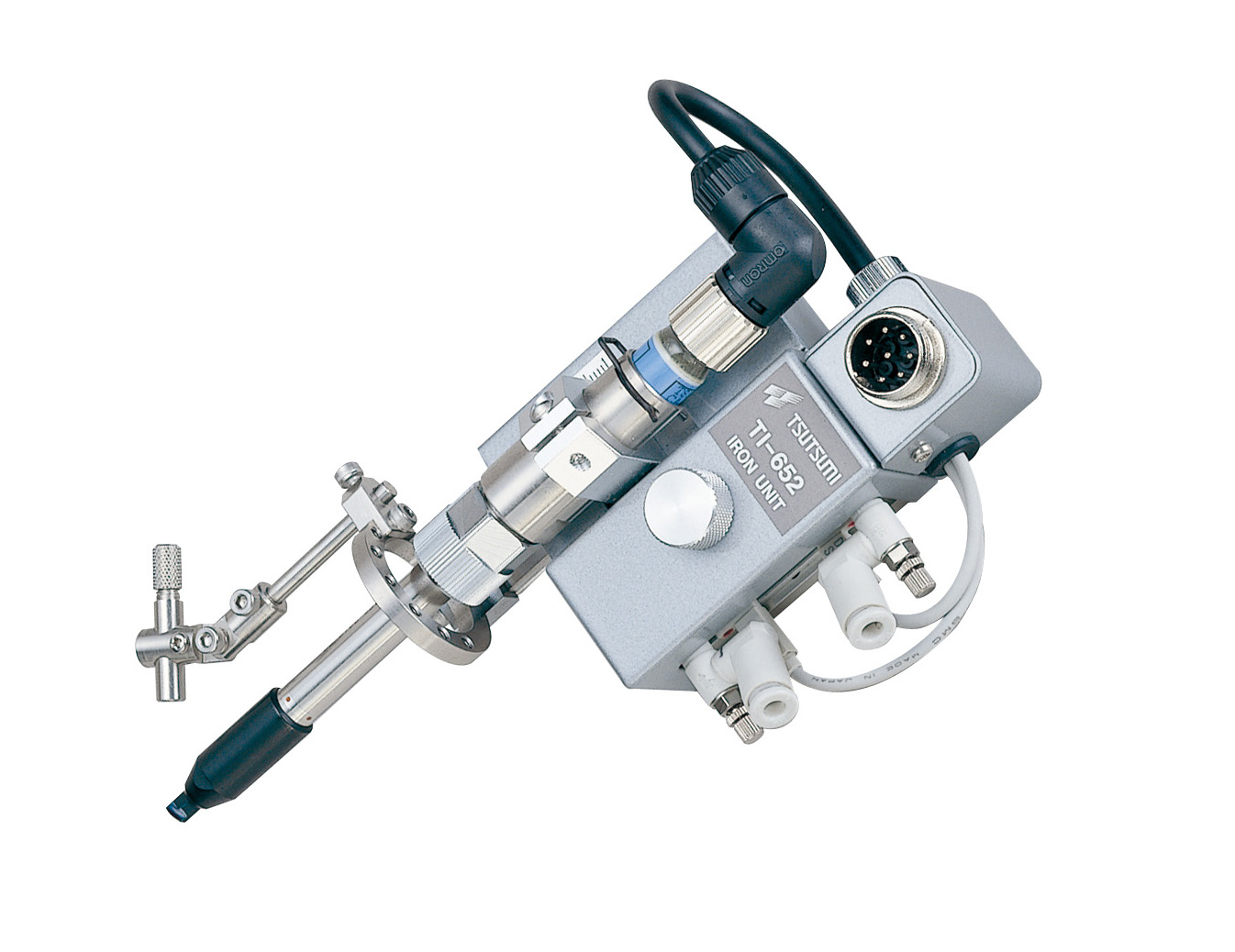

With a team of engineers with expertise, experience and long-term relationships with major partners in the field (Janome robot, Tsutsumi soldering unit), Temas is always confident to bring the best solutions at reasonable prices to customers. specific application.

Please register as a member, receive our newsletter to keep up to date with the latest technology or simply contact us directly when you need a supplier with sufficient expertise in the field to advise as well as provide solutions.

/Mainphoto-Temas-Tsutsumi-mCROSS TX-m444.jpg)

Read more

Read more