Do you have any of these problems?

- I can't find a "soldering robot" that supports in-line for automation.

- Is there a "soldering robot" that can handle large boards?

- I want the "soldering robot" to do other work.

- When I asked for repairs, I was told that I could not do it.

You can choose our Tsutsumi Welding Robot, with many outstanding advantages such as:

- There is a MINIMAX system - a system that is premised on automation that allows the robot part and the controller part to be separated.

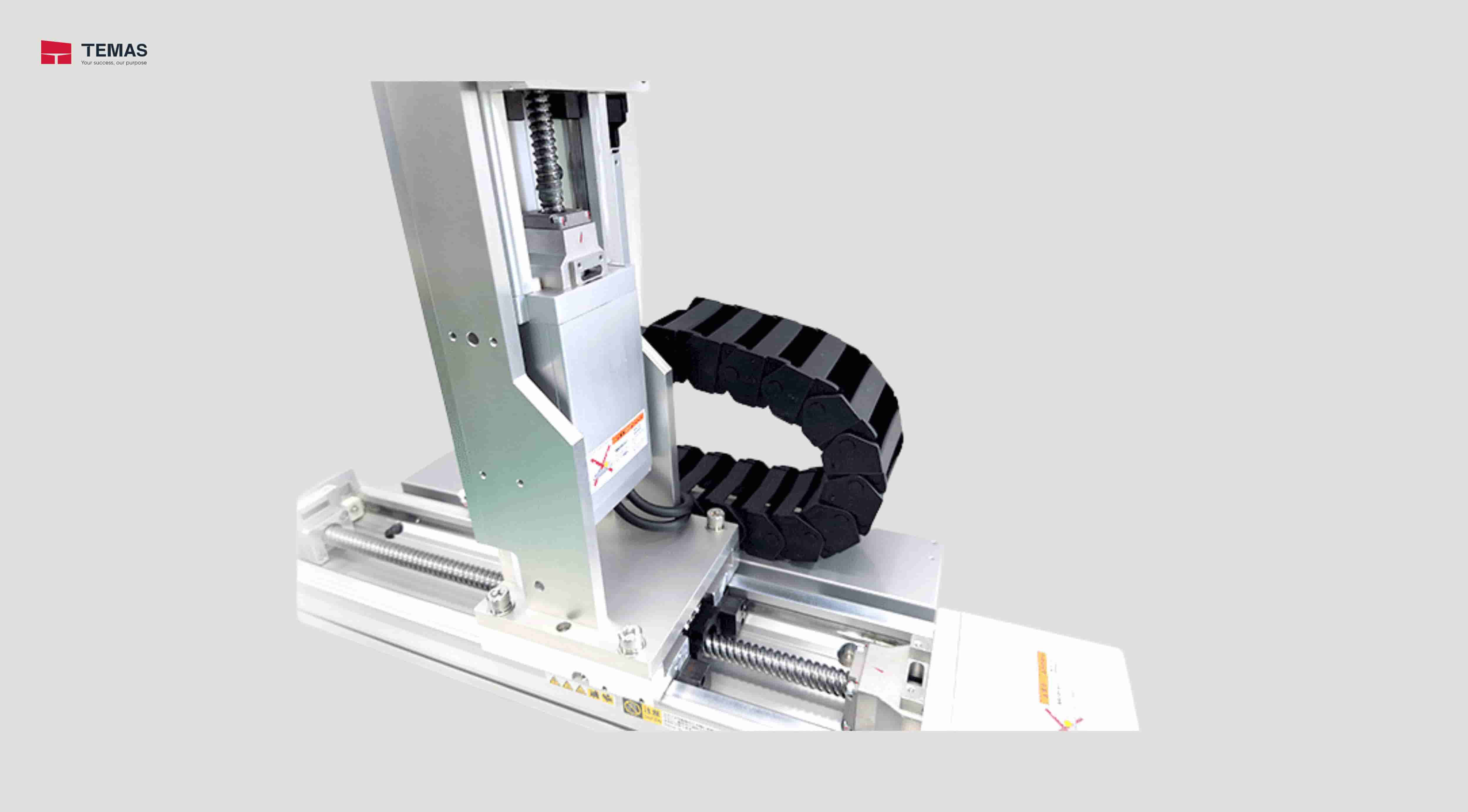

- Highly customizable: Robot sizes up to 1500 x 2000 mm can be produced.

- Reliability and Achievements: We have a lot of achievements such as safety specifications for automobile manufacturers.

- Reliable follow-up system: The division of responsibilities such as "soldering conditions" with automatic machine manufacturers is also clear with the automation-compatible MINIMAX system

- Realization of ideal equipment: combining fluxers, screw tightening, image inspection, etc., to realize the customer's ideal customization

- In-house manufacturing: Even customers who have been using it for nearly 20 years will be able to overhaul and repair as long as there are parts

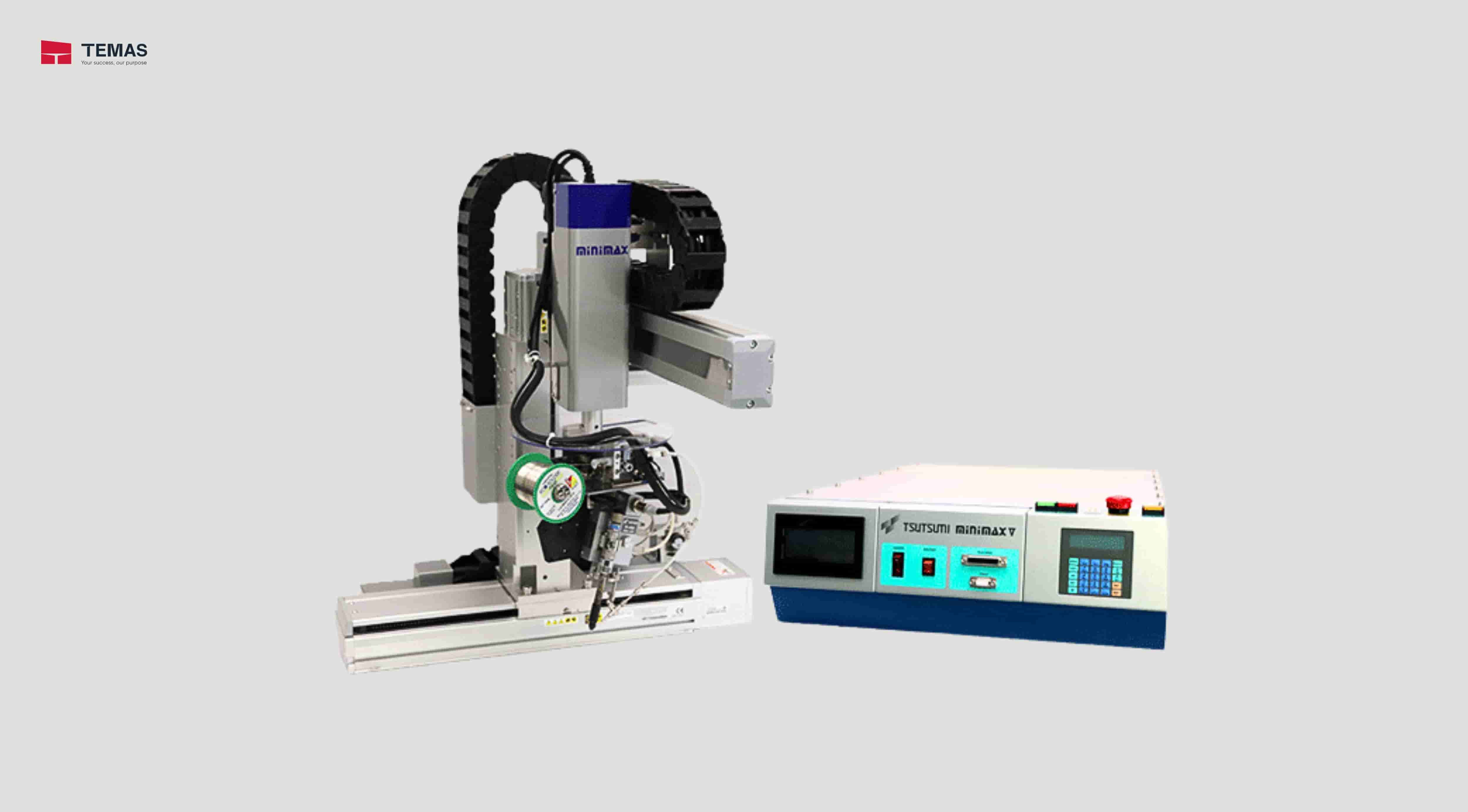

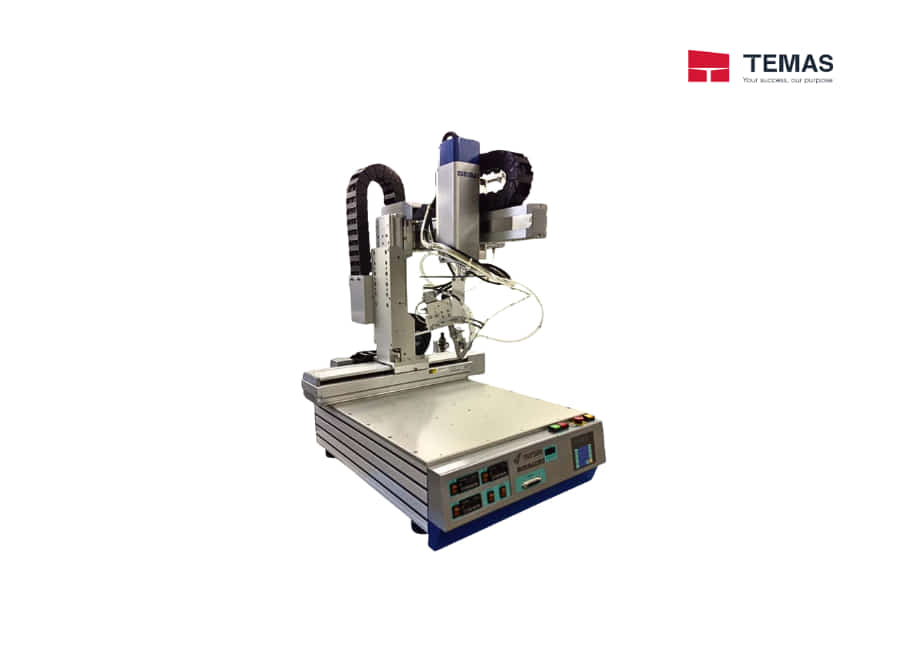

Developed with automation in mind, the MINIMAX V (TX-861) caters to the unique requirements of customers by offering extensive customization options including size, safety specifications, integration with other devices, and communication with external systems. We guarantee the delivery of "high-quality and stable soldering" achievable only through TSUTSUMI's in-house manufacturing of robots

Suitable for automation applications

The soldering robot MINIMAX V (TX-861) offers versatility in its configuration. It allows for easy installation either as separate controller and robot parts suitable for automated lines, or as an integrated type for cell production.

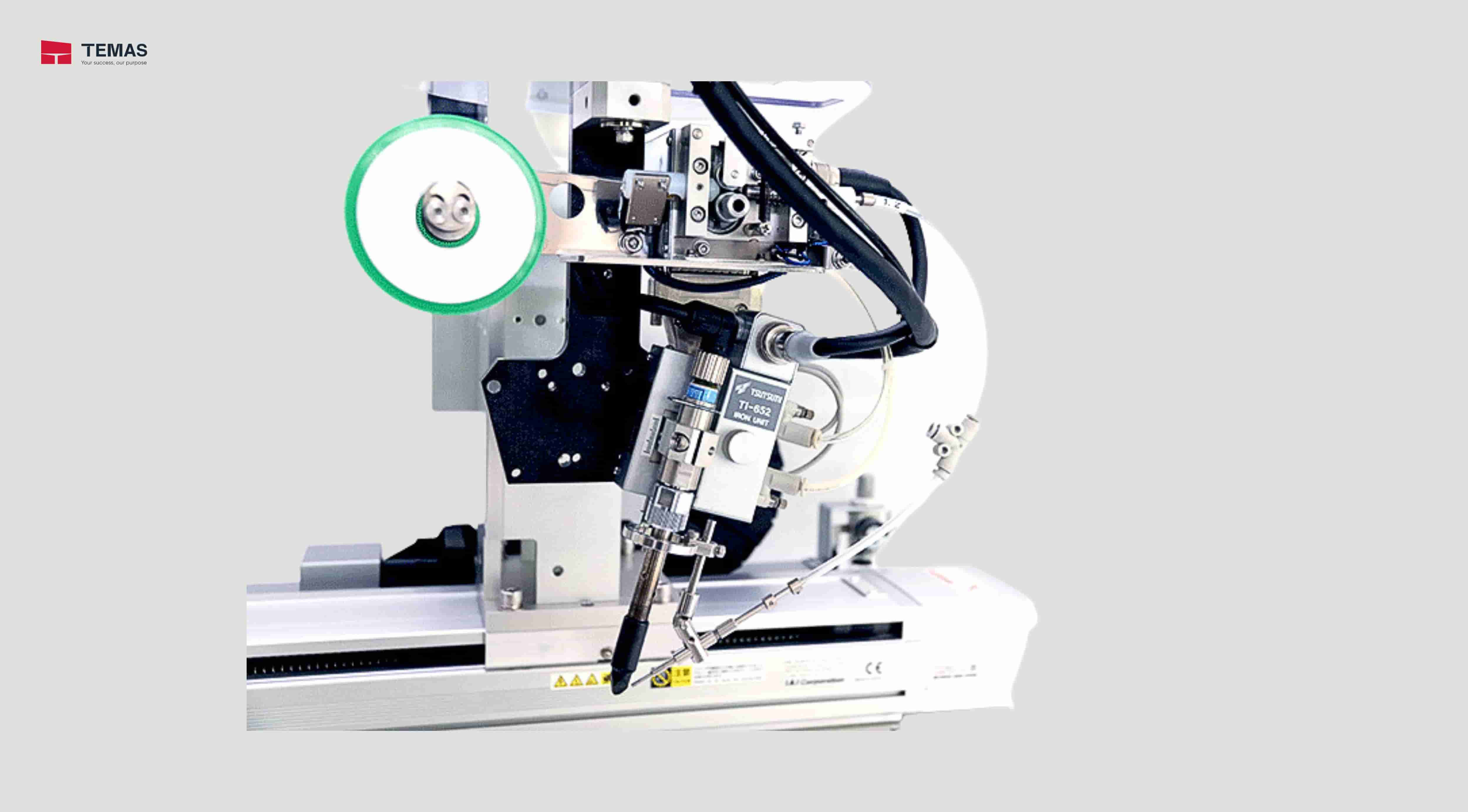

Capable of handling multiple rows or single rows simultaneously

The twin feeder method employed by this unique robot construction enables efficient multi-row soldering, reducing cycle time significantly compared to manual soldering.

Easy to extend

Soldering robot Tsutsumi MINIMAX V TX-861 is designed for easy extension and customization, particularly when combined with the twin feeder method and fluxer.

Traceability software

- Traceability information during the cycle is uploaded to the management PC by LAN connection.

- Recognition by 2D barcode: Soldering information, temperature, various errors, date and time cycle time, quality/failure judgment data of images acquired by the camera.

High rigidity and long service life

Many machines have been in operation for more than 10 years with high rigidity and long life due to servo motors and ball screw drives, and overhauls are also available.

Standard separate touch panel

As a standard feature, a separate touch panel is provided. This touch panel can be affixed to the trestle cover and serves to display the status of the soldering robot. It also enables effortless operation of various functions such as position correction.

Can be mounted on an integrated unit

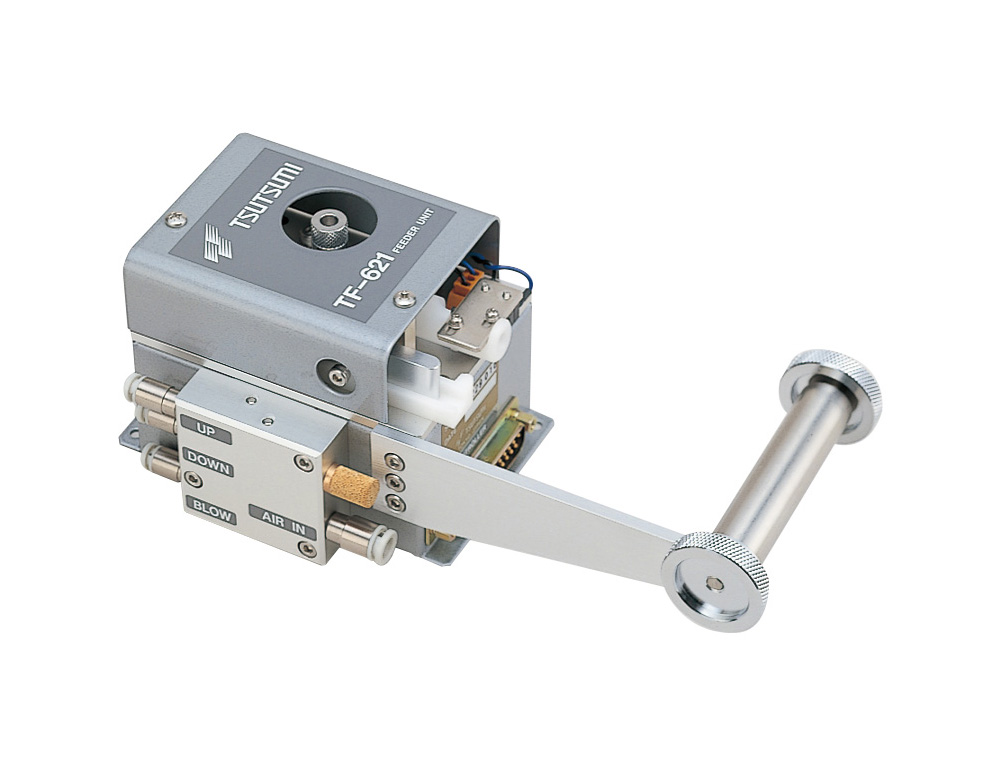

This compact unit achieves the miniaturization of the feeder unit while being integrated with the ironing unit. It effectively reduces solder jams and enhances precision in delivery.

Soldering Robot Tsutsumi MINIMAX V TX-861 is recommended for companies such as:

- Those seeking to enhance soldering quality through automation, replacing manual work.

- Those facing challenges in hiring skilled soldering technicians due to labor shortages.

- Those in need of a desktop-type soldering robot for automation purposes.

- Those aiming for efficient soldering of multi-row connectors.

- Those considering the use of large-sized or multifunctional soldering devices.

- Companies with strict safety standards requiring adherence to in-house specifications.

- Those planning to integrate soldering into automated production lines.

- Those striving to achieve optimal equipment performance.

Specifications of Robot Tsutsumi MINIMAX V TX-861:

| Specifications |

MINIMAX V TX-861 |

| Power requirement |

AC 200V - 230V 10% / 50, 60 Hz |

| Working environment |

0~40°C (No condensation, No corrosive gas) |

| Air requirement |

0.4~0.5 MPa (Dry air) |

Operation method,

No. of control axes |

PTP-control/4-axis in total (Simultaneous 3-axis linear and circular interpolation) |

|

| Performance of axes |

Stroke / Repeatability / Max. speed |

| X-axis |

300mm / +0.01mm / 1200mm/s |

| Y-axis |

300mm / +0.02mm / 800mm/s |

| Z-axis |

100mm /+0.01mm / 300mm/s |

| R-axis |

360° / 0.2° / 600 /s |

| No. of programs |

99 programs |

| Data storage capacity |

9999 program steps / 26,666 positions in total |

| Teaching method |

Direct teaching by MDI, Jogging using Teaching pendant |

| I/O |

Input |

Exclusive 16 points, General 10 points |

| Output |

Exclusive 18 points, General 10 points |

| Soldering conditions |

511 freely programmable blocks |

| Soldering operation |

Point and slide soldering |

| Weight |

60kg |

Frequently Asked Questions (FAQs)

What preparations are necessary for the test?

You should prepare approximately 5 to 10 sets of work samples and provide solder materials along with non-defective samples that will be utilized during testing. Evaluation of new samples intended for introduction is generally conducted at no cost. However, additional tests such as data acquisition and prototypes for mass production may incur separate charges, which can be discussed through consultation.

What is the expected lifespan of the trowel tip and its replacement cycle?

For point soldering, the trowel tip typically lasts between 20,000 to 50,000 points, while for slide soldering (multiple rows), it ranges from 20,000 to 100,000 points. Nevertheless, we have a proven track record of extending the service life by over three times through the utilization of custom-made trowel tips with long-life specifications and solder materials designed to minimize wear and tear.

What is the delivery time for the equipment??

This may vary depending on custom specifications and parts availability. Therefore, please consult separately depending on the timing of your order.

Can it be integrated with flux application?

Yes, integration with a flux application unit is feasible. Many users utilize it as a multifunctional device.

Can I buy the Soldering robot Tsutsumi MINIMAX V TX-861 at overseas locations?

Tsutsumi have established distributors in China, India, Vietnam, Thailand, and Mexico, with a comprehensive support system in place. For Vietnam regions, you can contact Temas - the official distributor of Tsutsumi. For other regions, Tsutsumi may coordinate support through a trading company or directly from Japan.

/Mainphoto-Temas-Tsutsumi-mCROSS TX-m444.jpg)