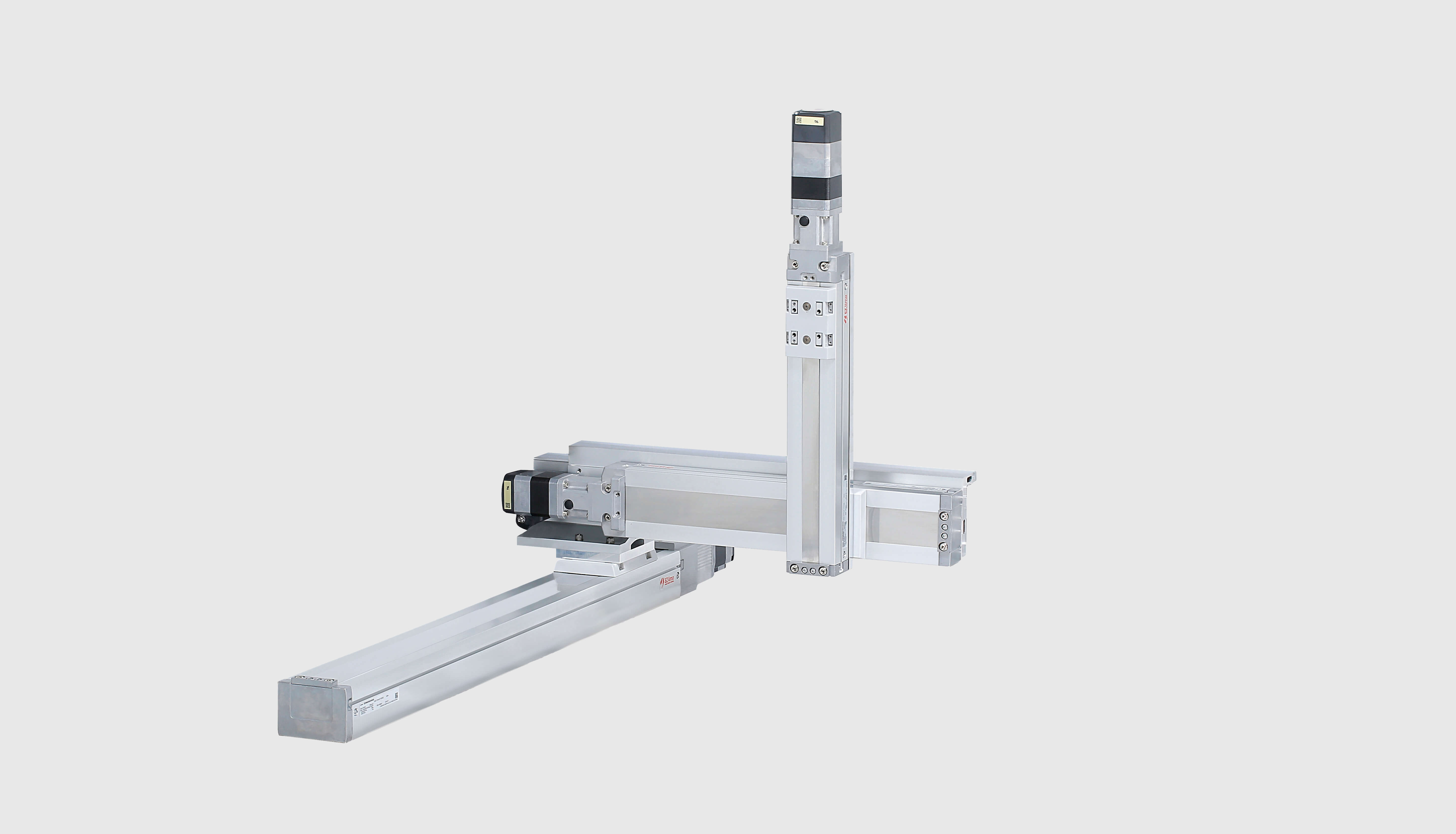

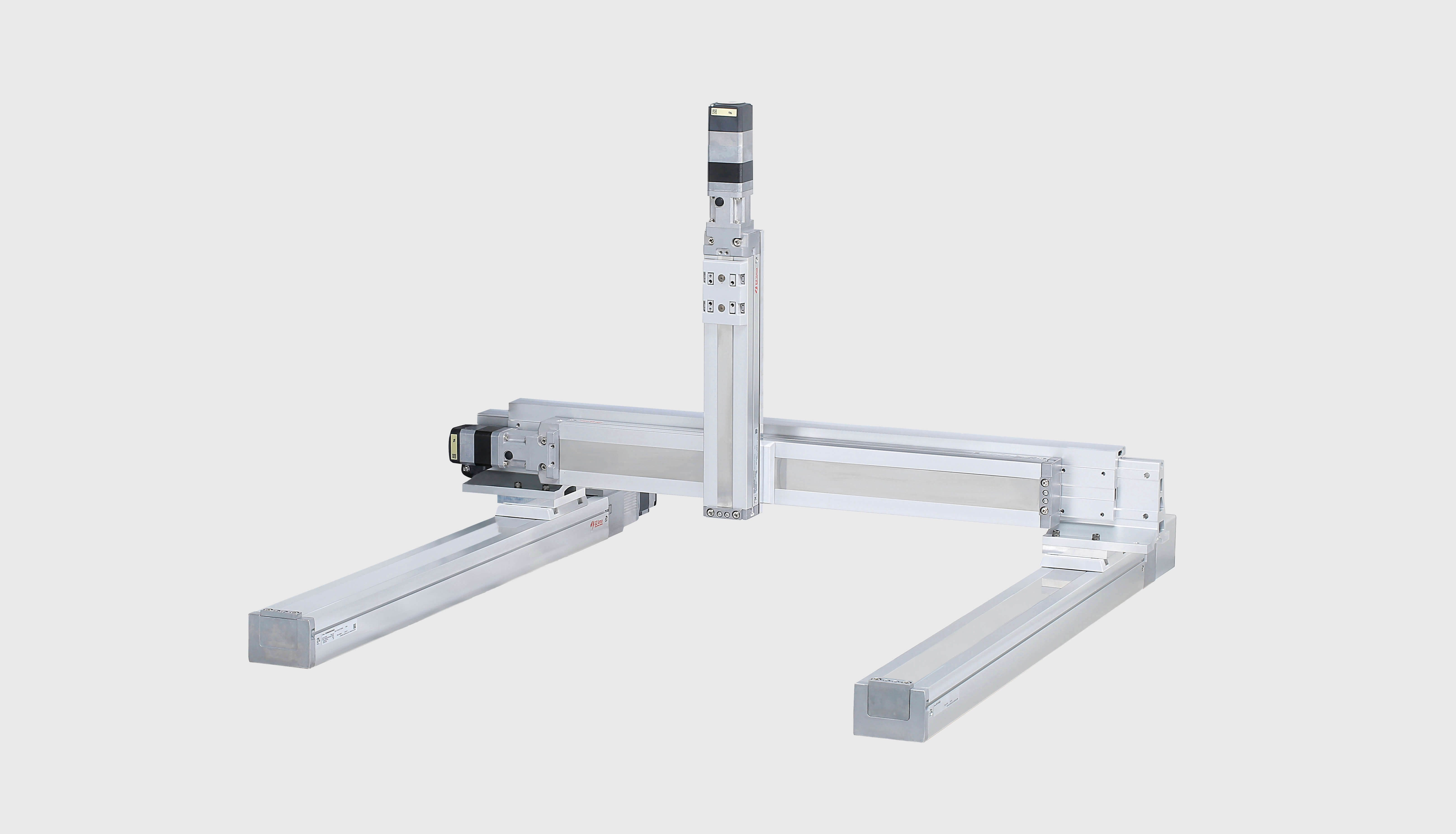

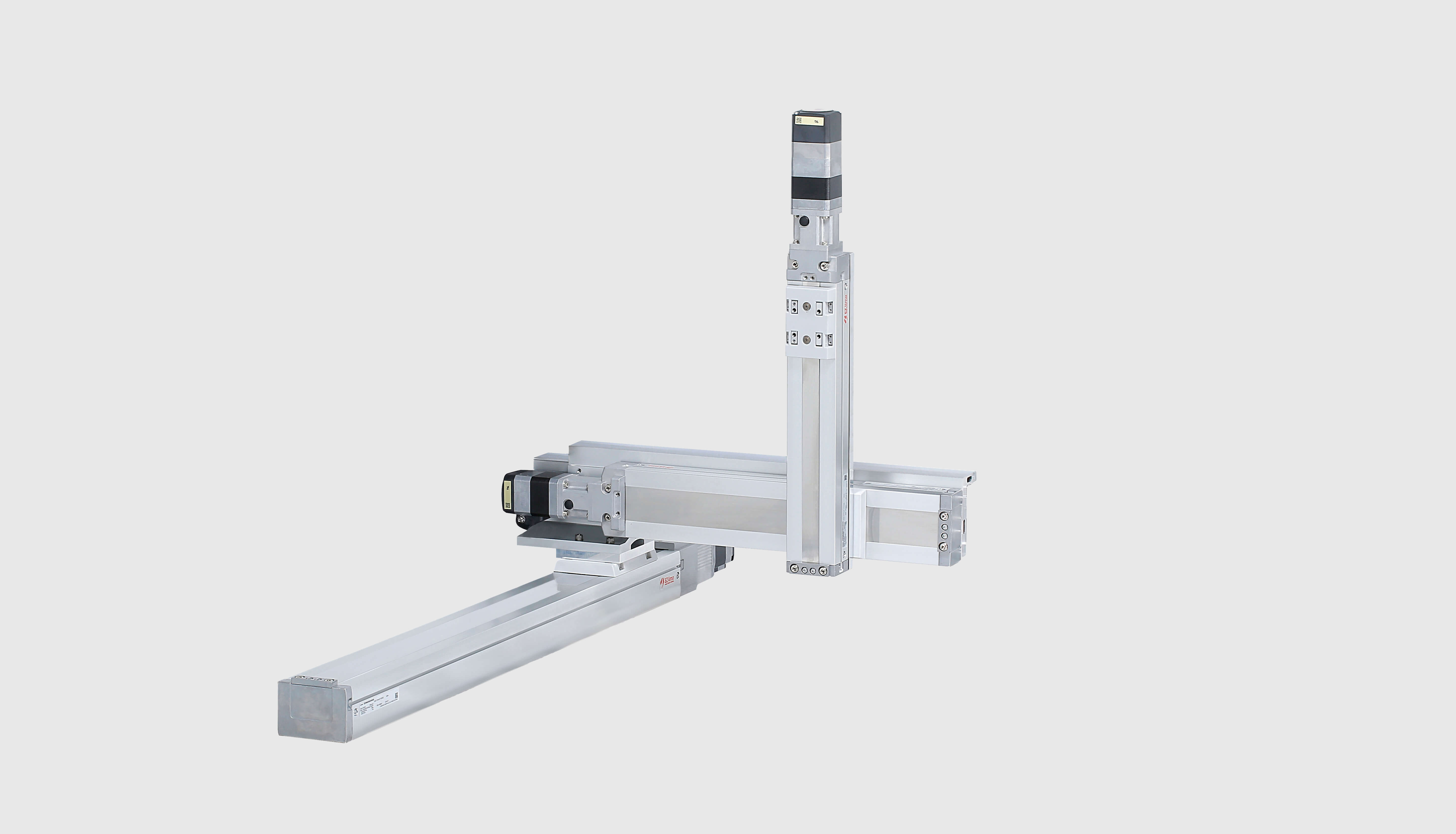

Multifunctional Cartesian robot with plenty of stroke combinations

Model: JC-3A00-0T3, JC-3A00-0H3, JC-3B01-0H4

| Model | JC-3A00-0T3 | JC-3A00-0H3 | JC-3B01-0H4 | ||||

| Control Axes Directions | 3(XYZ) | 3(XYZ) | 4(XYZR) | ||||

| Stroke | X Axis(mm) | 200/300/400/500/600 | 300/400/500/600 | 300/400/500/600 | |||

| Y Axis(mm) | 200/300 | 200/300/400/500 | 200/300/400/500 | ||||

| Z Axis(mm) | 50/100/150/200 | 50/100/150/200/300 | 100/150 | ||||

| R Axis(deg) | - | - | ±360 | ||||

| Drive Motor | Stepping Motor | Stepping Motor | Stepping Motor | ||||

| X Axis | Feedback Control | Feedback Control | Feedback Control | ||||

| Y Axis | |||||||

| Z Axis | Open Loop Control | ||||||

| R Axis | - | - | |||||

| Maximum Portable Load |

Tool(kg) | 4 | 8 | 3 | |||

| Maximum Speed *1 |

X-Axis Stroke | 200 300 400 |

500 600 |

300 400 |

500 600 |

300 400 |

500 600 |

| X Axis(mm/s) | 700 | 800 | 700 | 800 | 700 | 800 | |

| Y Axis(mm/s) | 800 | 800 | 800 | ||||

| Z Axis(mm/s) | 400 | 400 | 400 | ||||

| R Axis(deg/s) | - | - | 900 | ||||

| R Axis Acceptable Moment of Inertia (kg・cm2) |

- | - | 90 | ||||

| Repeatability(mm)*2 | X Axis(mm) | ±0.02 | ±0.02 | ±0.02 | |||

| Y Axis(mm) | ±0.02 | ±0.02 | ±0.02 | ||||

| Z Axis(mm) | ±0.02 | ±0.02 | ±0.01 | ||||

| R Axis(deg) | - | - | ±0.008 | ||||

| External Dimensions (excluding cables and protrusions) W x D x H(mm) |

Robot | W:Y-Axis Stroke + 319 D:X-Axis Stroke + 309 H:Z-Axis Stroke + 357 |

W:Y-Axis Stroke + 426 D:X-Axis Stroke + 309 H:Z-Axis Stroke + 357 |

W:Y-Axis Stroke + 426 D:X-Axis Stroke + 309 H:Z-Axis Stroke + 334 |

|||

| Controller | 170 x 310 x 300 | ||||||

| Mass(kg) | Robot | Varies depending upon stroke combination. | |||||

| Controller | 7.5 | ||||||

*1 This value reflects the maximum portable load when measured with all the axes assembled. For information about acceleration rates, please refer to the speed & acceleration materials in the Catalog section of our Catalog and Diagram Download page. Maximum speed may be unreachable depending upon the tool attachment setup. The X and Y axes individual unit speed and acceleration are 800mm/s and 5000mm/s2 respectively.

*2 We measured repeatability at a constant temperature according to our internal methods.

This measurement does not represent a guarantee of absolute precision.

| Control Method | PTP (Point to Point) control, CP (Continuous Path) control | |

|---|---|---|

| Interpolation | 3-dimensional linear and arc interpolation | |

| Teaching Method | Remote Teaching (JOG)/Manual Data Input (MDI) | |

| Teaching System |

|

|

| Teaching Pendant Display |

Measurement Units | mm/inch |

| Languages | Switch back and forth among these languages: Japanese・English・German・Italian・Spanish・French・Korean・Simplified Chinese・Traditional Chinese・Czech・Vietnamese. | |

| Program Capacity | 999 programs | |

| Data Capacity | Maximum 32,000 Points*3 | |

| Simple PLC Function | Maximum 100 Programs 1,000 steps/Program | |

| External Input/Output | I/O-SYS*4*6 | 16 Inputs, 16 Outputs |

| I/O-1*4*6 | 8 Inputs, 8 Outputs | |

| I/O-MT (optional) |

for auxiliary axes (pulse string input type*8) control, control up to 2 axes |

|

| Fieldbus (optional) |

Choose CC-Link, DeviceNet, PROFIBUS, EtherNet/IP, PROFINET or CANopen | |

| COM Port (RS232C) | COM1, COM2, COM3: for external device control | |

| MEMORY Port | For USB memory connection

|

|

| LAN*5 | For PC connection via the Ethernet

|

|

| TPU | Dedicated teaching pendant (optional) connector | |

| SWITCHBOX | Dedicated switchbox connector | |

| EMG OUT | For external safety circuit connection*9 | |

| I/O Built-in Power Supply (optional) | DC24V | |

| Power Source | AC90~240V (single phase) 50/60Hz + external DC48V (depending upon facility supply)*7 |

|

| Power Consumption | 150W (AC Power Supply) 300W (DC48V, motor drive power supply) |

|

| Operating Environment | Operating Temperature | 0~40℃ |

| Relative Humidity | 20~85% (without condensation) | |

| Elevation | Up to 1,000m | |

*4 When using an internal power supply, an (optional) built-in I/O power supply is required.

*5 LAN connection is 10BASE-T, 100BASE-TX.

*6 There are two types of I/O polarity: NPN specifications and PNP specifications.

*7 With the 4 Axes Specifications, the XY Axes are powered externally at 48V, while the ZR Axes use a 24V control power supply.

*8 We ask customers to please prepare their own control power supply, pulse motor and motor driver.

*9 We ask customers to please construct their own safety circuit.