The pulse motor and micro-step driver control combination saves energy by reducing power consumption.

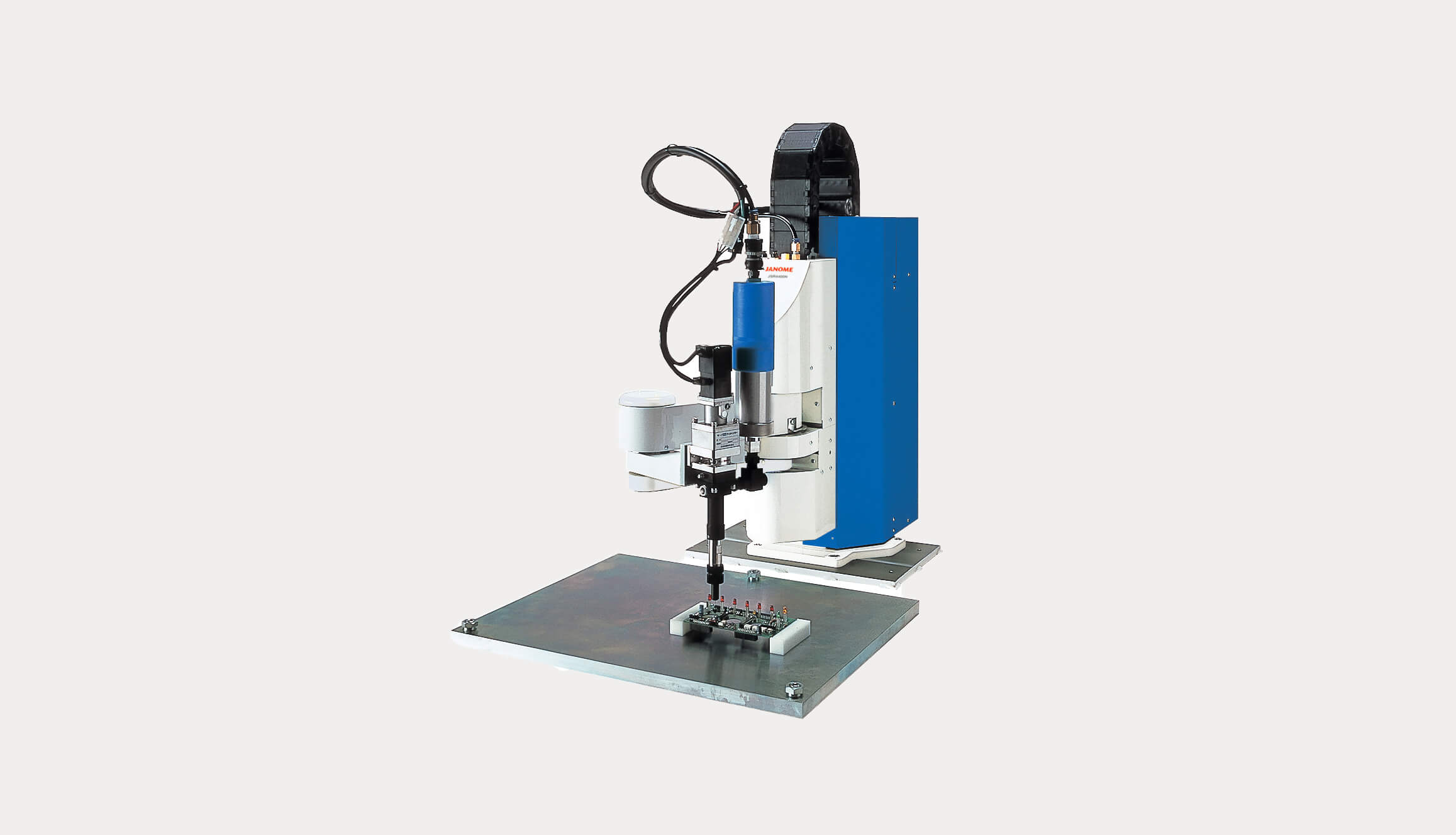

Model: JSR4403N, JSR4404N

| Model | JSR4403N (3 Axes) | JSR4404N (4 Axes) | |

| Arm Length | J1 Arm(mm) | 260 | |

| J2 Arm(mm) | 180 | ||

| J1+J2(mm) | 440 | ||

| Operating Range | J1 Arm( °) | ±90 | |

| J2 Arm( °) | ±150 | ||

| Z Axis (mm) | 100 | ||

| R Axis ( °) | - | ±360 | |

| Maximum Portable Load(kg) | 5 | ||

| PTP Maximum Speed*1 | J1, J2 Combined (mm/sec) | 1,450 | |

| Z Axis (mm/sec) | 320 | ||

| R Axis ( °/sec) | - | 1,000 | |

| CP Maximum Speed(mm/sec)*1 | 750 | ||

| Repeatability*2 | X Axis ・Y Axis (mm) | ±0.02 | |

| Z Axis (mm) | ±0.01 | ||

| R Axis ( °) | - | ±0.02 | |

| Main Unit Weight(kg) | 39 | 40 | |

*1 Maximum speed may vary depending upon conditions. Maximum speed cannot be achieved when the robot is bearing its maximum portable load.

*2 Repeatability is limited to situations where the robot is operating at a constant temperature and therefore absolute precision is not guaranteed.

| Drive Method | Pulse Motor |

|---|---|

| Control Method | PTP (Point to Point) control, CP (Continuous Path) control |

| Interpolation | 3-dimensional linear and arc interpolation |

| Teaching Method | Remote Teaching (JOG)/Manual Data Input (MDI)/Direct Teaching |

| Teaching System | ・Direct teaching via the optional teaching pendant ・Off-line teaching via a PC with JR-C-Points Software |

| Program Capacity | 255 Programs |

| Data Capacity *3 | Up to 30,000 Points |

| External Interface | RS422 1ch (for teaching pendant) RS232C 1ch (for PC interface: COM1) RS232C 2ch (for external devices: COM2, COM3) |

| External Input/Output | I/O-SYS 17 Inputs, 16 Outputs I/O-1 8 Inputs, 8 Outputs (including 4 relays) |

| Power Source | AC90~132V/AC180~250V (Single Phase) |

| Power Consumption | 200W |

*3 Point data capacity reduces as the total function data setting / point job data / sequencer data increases, due the shared data storage area.