Highly rigid robot arm for speed, precision and heavy payload capacity

Model: JS3-3520, JS3-4520, JS3-5520

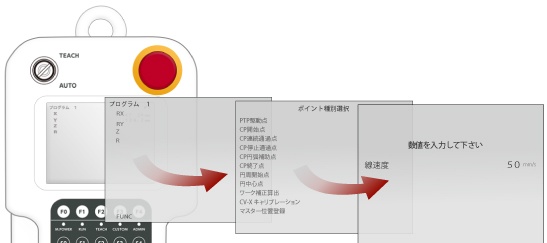

1. Make operation settings without writing a new robot language

Dedicated Pick & Place software prepared with all the command types you need. Just choose the robot movements from the menu.

Pre-programmed software shortens setup and teaching time.

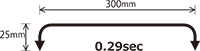

2. Top Class High Speed Movement and Short Standard Cycle Time

Maximum Speed: 8,300mm/sec Standard Cycle Time: 0.29sec

Enhanced high speed movement and continuous operability for increased productivity.

3. Cable and Tube Passage Inside the Robot Mechanism

Internal wiring and air tubing to minimize interference from peripheral devices and cables.

4. Expanded Pivot Axis Operating Range

The area behind the robot is accessible, eliminating wasteful extra movement and increasing robot installation flexibility.

5. Additional Robot Maintenance Functions

Use the robot's running data record as a guide for when to perform maintenance or replace consumable parts.

6. Comprehensive External Interfaces

LAN (Ethernet) port, USB memory port, 6 Field Network options, add up to 2 optional auxiliary axes.

7. Making Programs Is Easy

Use our original PC software or our teaching pendant.

● Optional Teaching Pendant II

Our interactive input method makes direct teaching easy.

● Optional "JR C-Points II" PC software

Large icons on the software screen make program creation easy.

Create, edit and save teaching data and customizing data.

We also offer a convenient point graphic editing function.

● Point Graphic Editing Function

With this function upload DXF files, Gerber data or jpeg data and draw points, straight lines, circles and arcs.

Our motion-based approach accurately determines difficult positions on your PC screen.

For DXF files and Gerber data, you can edit their coordinate information.

8. Built-in Simple PLC Function

Handles simple communication with external devices; no need for an external PLC.

9. Multi-lingual Compatibility

Switch among 5 display languages with our PC software and 11 display languages on our teaching pendant.

| Model | JS3-3520 | JS3-4520 | JS3-5520 | |

| Number of Control Axes | 4 | |||

| Arm Length | Maximum(J1+J2) | 350mm | 450mm | 550mm |

| J1 Axis | 125mm | 225mm | 325mm | |

| J2 Axis | 225mm | |||

| Operating Range | J1 Axis | 340(±170)° | ||

| J2 Axis | 290(±145)° | |||

| J3 Axis | 200mm | |||

| J4 Axis | 720(±360)° | |||

| Maximum Speed | Combined (J1+J2+J4)*1 |

6900mm/sec | 7600mm/sec | 8300mm/sec |

| J3 Axis | 2080mm/sec | |||

| J4 Axis | 2500°/sec | |||

| Standard Cycle Time*2 | 0.29sec | |||

| Portable Mass | Maximum 6 kg (Rating 3kg) | |||

| Acceptable Moment of Inertia | Maximum 0.12kgm² (Rating 0.01kgm²) | |||

| Repeatability*3 | Combined (J1+J2) | ±0.010mm | ±0.012mm | |

| J3 Axis | ±0.010mm | |||

| J4 Axis | ±0.004° | |||

| External Dimensions W×D×H*4 Weight |

Robot Unit | 174×572×798mm | 174×672×798mm | 174×772×798mm |

| 36kg | 37kg | |||

| Controller | 400×350×288mm | |||

| 16kg | ||||

| Z Axis Resistance*5 | 165N | |||

| Tool Wiring | ・I/O-H 8 Hand Inputs/8 Hand Outputs ・LAN Cable <100BASE-TX> |

|||

| Air Piping | ・Primary: ?6×2 Tubes ・Secondary: ?4×8 Tubes (Optional) |

|||

| Control Method | PTP (Point to Point), CP (Continuous Path) | |||

| Interpolation | 3-dimensional linear and arc interpolation | |||

| Teaching Method | Remote Teaching (JOG), Manual Data Input (MDI) | |||

| Teaching Pattern | ・Direct teaching using optional Teaching Pendant II ・Offline teaching using optional JR C-Points II PC Software ・CAD Data (DXF, Gerber, jpeg) compatible |

|||

| Program Capacity | Maximum 999 Programs | |||

| Database Capacity*6 | Maximum 32,000 Points | |||

| Simple PLC Function | Maximum 1000 Steps | |||

| Screen Display Languages | PC Software | English, Japanese, German, Chinese (both Simplified & Traditional) | ||

| Teaching Pendant | English, Japanese, German, Italian, Spanish, French, Korean, Chinese (both Simplified & Traditional), Czech, Vietnamese | |||

| External Input/Output | LAN | For robot control via control commands and connection to JR C-Points II PC Software | ||

| MEMORY | USB Memory Connector (for saving and reading out teaching & customizing data, and for upgrading system software) | |||

| I/O-SYS | 15 Inputs/14 Outputs *Please choose NPN/PNP when ordering | |||

| I/O-1 | 18 Inputs/22 Outputs (including 4 relay outputs) | |||

| I/O-S | for safety device connection | |||

| I/O-H | 8 Hand Inputs/8 Hand Outputs | |||

| COM1, COM2 | RS-232C (External Device Control & COM Commands) | |||

| I/O-MT (Optional) | Motor Control, Auxiliary Axes 2 Channels | |||

| Fieldbus (Optional) |

CC-Link, DeviceNet, PROFIBUS, PROFINET, CANopen, EtherNet/IP | |||

| Other | Teaching Pendant Connector | |||

*1 This is the J1, J2 and J4 axes' maximum speed with a control point on a flat X-Y surface. (The control point is a position 30mm from the center of the J4 axis' rotation.)

*2 Value when bearing a 2kg load. Cycle time may increase when precision workpiece positioning is necessary or due to the robot's operating position(s).

*3 Repeatability is not a guarantee of absolute precision.

*4 These are the dimensions when the J1 and J2 axes are positioned at 0°.

*5 The downwards pressing force at the tip of the load when the robot is bearing its maximum load and the J1, J2 and J4 axes are at rest. An excess load error may occur if a pressing force is applied for an extended period of time.

*6 Data is made up of job data, additional function data and PLC program data in a shared data storage area. As these data increase, the point memory capacity reduces, and the maximum number of points may become unreachable.