"Part Feeder" is almost in integrated automation systems. Used to store, sort, orient, allocate, locate, and deliver the components needed for the next cycle.

It is commonly used in assembly lines to automate production with a wide range of options to ensure to meet fully the need of the specific operation and application. One of the most popular automatic part feeding systems is the "hopper feeder".

"Hopper feeder" has many variations: the most popular is vibrating hopper, centrifugal rotating, linear vibrating rod, rotating cage with vibrating rod, ladder, and pneumatic hopper...

Each type offers distinct characteristics suitable for different applications. In the following, we will outline the features, key advantages, and typical applications of the hopper feeders mentioned above.

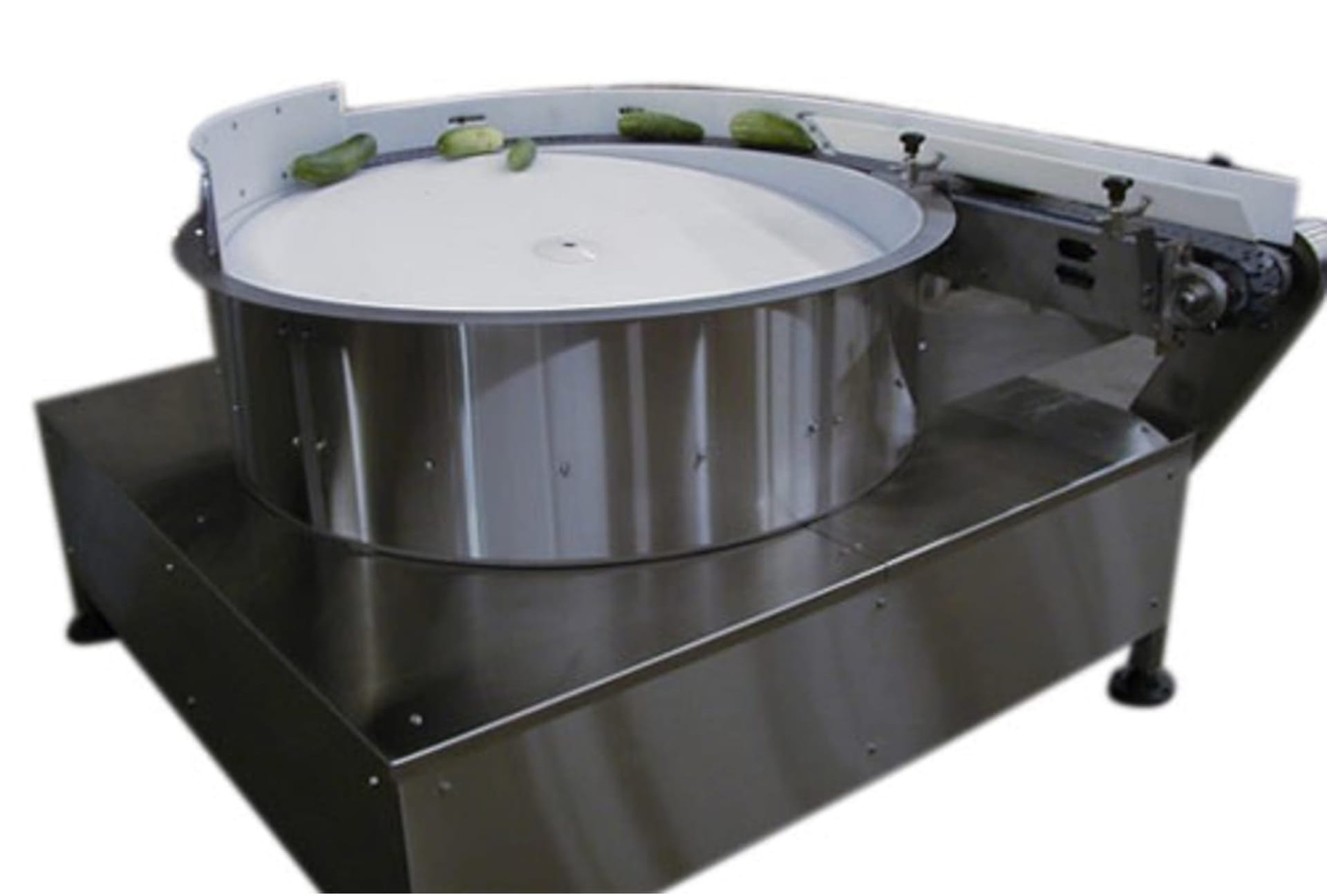

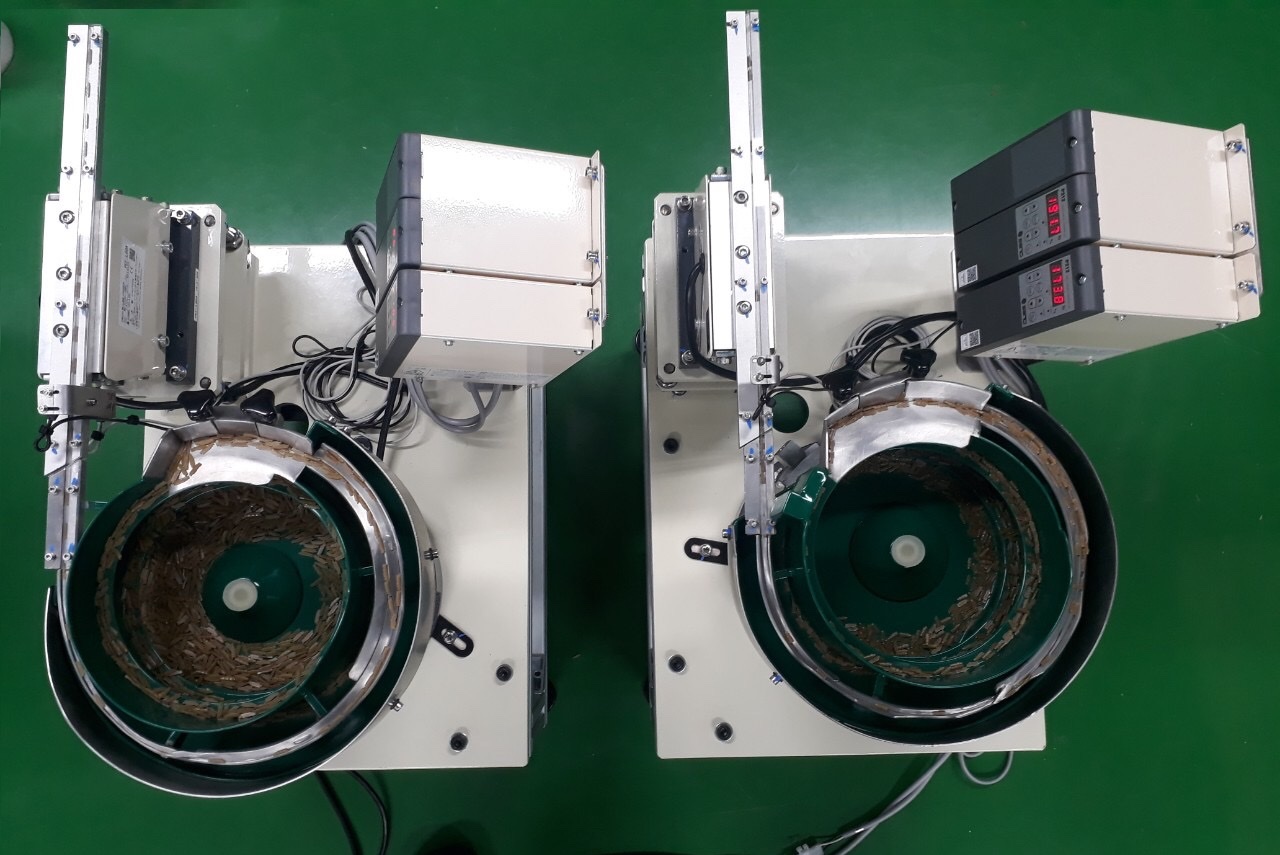

BOWL PART FEEDER

Bowl Part Feeder consists of four basic components: base, hopper, spring, and coil.

The hopper will be designed according to the application, the material is also optional depending on the requirements (e.g. stainless steel or polyamide). Coating material (e.g. epoxy, neoprene, or polyurethane) and size (typically 100-1500mm).

Regardless of the design and construction of the part feeder, they all rely on a combination of vibration, gravity, and balance to get parts onto the assembly line.

Forced oscillation is generated by an electromagnetic mechanism attached to the spring. When current flows through the mechanism, it creates vibrations of a certain frequency that move the hopper, forcing the parts to move gradually along the hopper's path.

The control mechanism of the system allows the intensity and frequency of vibration to be adjusted to suit different types of parts, sizes, and weights.

Compared with other types of part feeders, this type is simple with small investment costs. In addition, they are fully customizable, safe, and easy to operate, with low maintenance costs. One of the most versatile types of bar feeders available, suitable for very small to very large parts for assembly, control, and packaging operations.

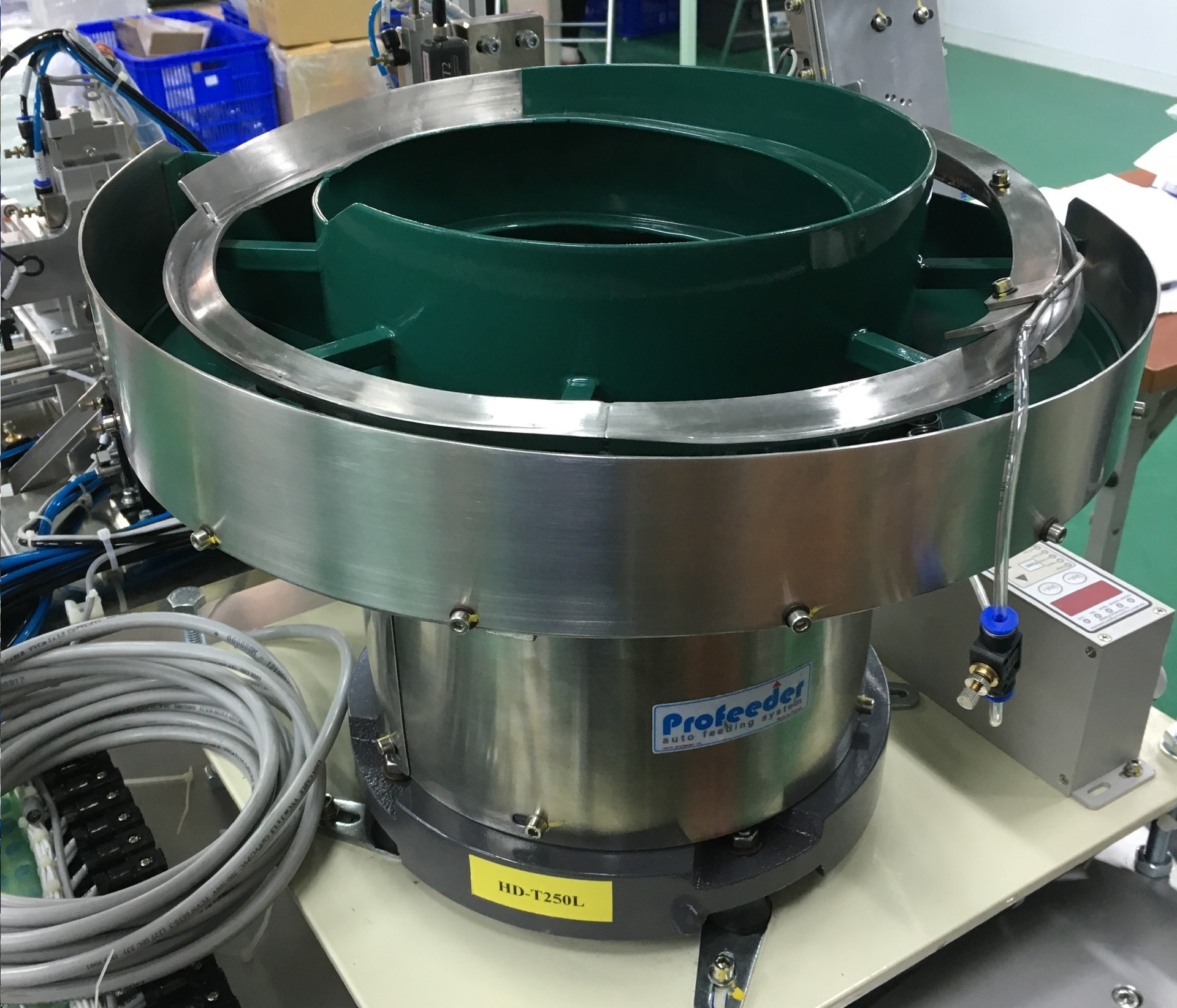

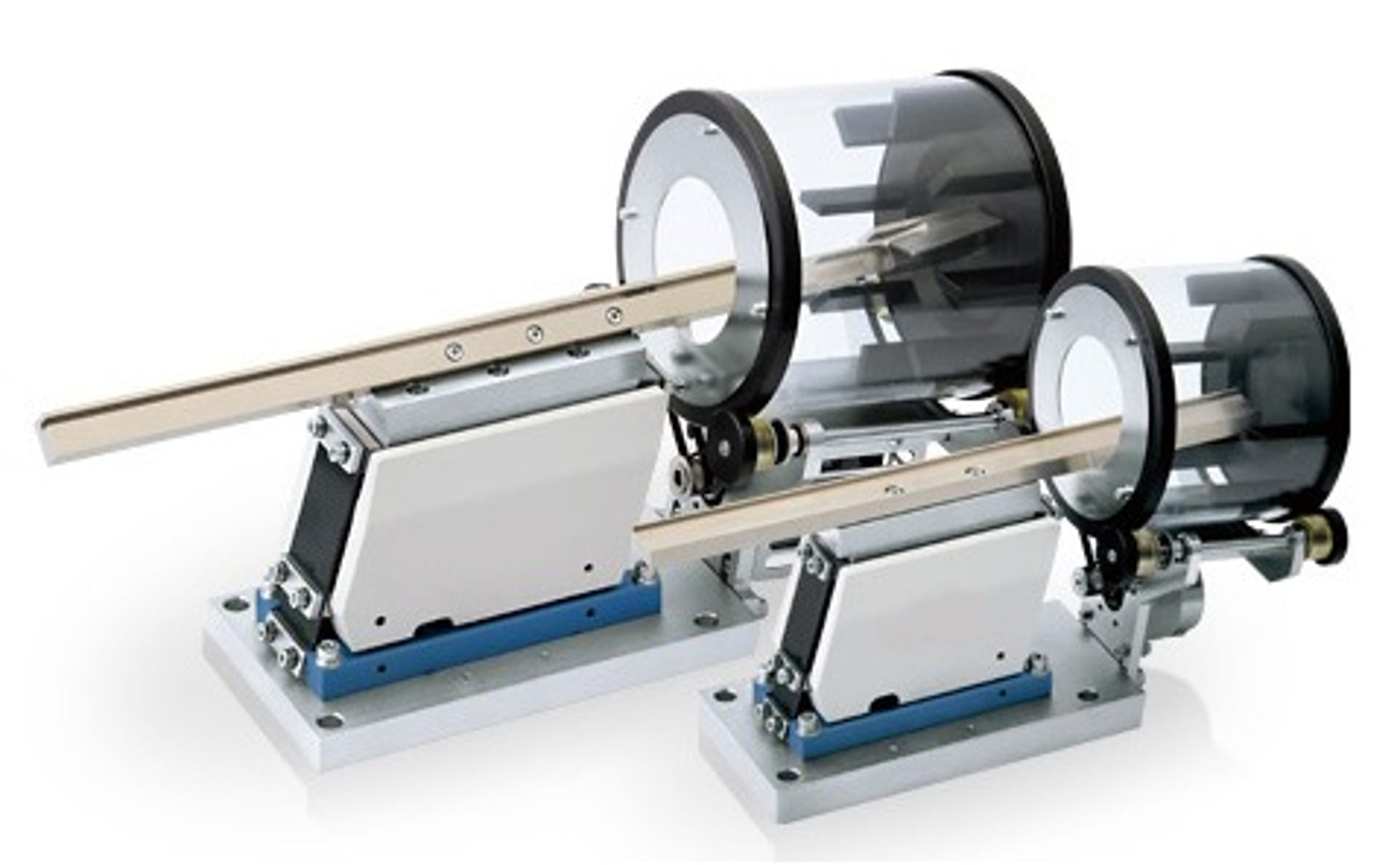

ROTARY PART FEEDER

Centrifugal feeders use a tray combined with an electrically powered rotary motor to orient the parts. The rotating trays generate centrifugal force, which guides the parts to the edge of the hopper.

At the edge of the tray is a separate guide mechanism that will guide them into the proper position before they enter the assembly line.

Compared with other types of feeders (e.g. bowl part feeder), this device provides much quieter and faster operation (up to 1,000 parts/min).

In addition, since they do not rely on vibration for movement and positioning, they are suitable for use with small and delicate parts, even in high-speed part feeder operations.

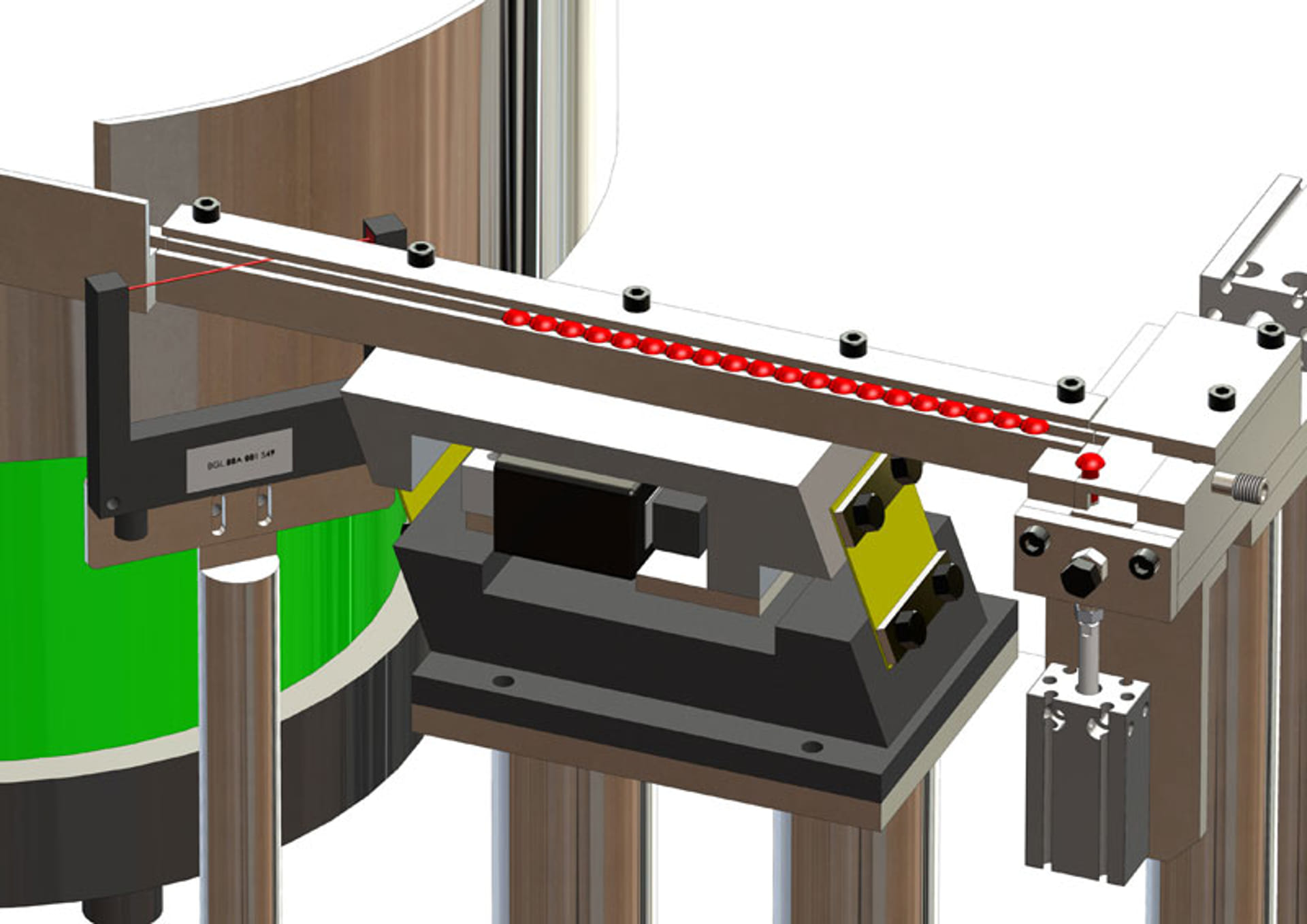

LINEAR FEEDER

Linear feeders are commonly used to convey parts that other bar feeders (e.g. bowl part feeders) have oriented to the next workstation in the assembly line.

Although they all serve the same function, they can be operated by different shipping methods depending on the type, size, and weight of the components.:

Vibrating linear feeder: As its name, this method relies on vibrations to guide components running along a rail. Although it has stability and slower operation than other methods, it is much cheaper and has a better capacity to accommodate complex parts.

Conveyor: This method is often used in conjunction with centrifugal feeders to move sorted and oriented objects between assembly stations. Using conveyors allows for faster and quieter conveying and easier adjustment than other linear feeders.

Pressure: This method uses pneumatic or blower elements to create a flow of air to move the parts along the feeder rails. This is an ideal method for navigating parts along a rail with requirements for increasing or decreasing the height.

While they are suitable for high-speed part feeding operations - including small or delicate parts - they produce more noise and require a more substantial investment than other options.

Gravity: This method utilizes gravity to move and orient parts. Although these methods are less expensive, smooth, and easier to maintain than other linear feed systems, they have design limitations.

They must be designed at a suitable height to allow the components to move along the descent efficiently. This requirement can make it difficult to access and maintain the tool for repair and maintenance operations.

RESERVED HOPPER

Similar to linear feeders, reserved hoppers are often used in conjunction with centrifugal or bowl part feeders. However, they are positioned above - not below - relative to these feeders.

They rely on vibrations to guide parts to the next station in the production line. Their size and storage capacity can be tailored to the needs of specific operations and applications.

The main advantage of using a vibrating hopper is its ability to help optimize operations. It reduces and/or eliminates the need to manually feed new details into the system.

ROTATING CAGE FEEDER

Rotating cage feeder commonly used to separate easily adhered and stuck parts such as springs. It is designed with an inclined rotating cage combining with separators inside the cage, a trap section, and a part guide at the end to direct the parts in the desired direction.

The rotating part is done by the motor. The output of a rotary cage feeder usually incorporates linear guides to move the next station.

STEP PART FEEDER

Step part feeder is applied to all kinds of parts from small to large, however, it is really effective when making simple block profiles (pillars, discs, ...) that have a large mass and can stick grease.

The system uses a mechanism that converts rotary motion from the motor to parallel up and down movements step by step (similar to a ladder). In these steps, traps will be arranged to remove components that do not rule to the desired output direction.

The system is durable and has a large load, but it also requires a complex mechanical structure and much cost.

PNEUMATIC FEEDER

Pneumatic feeder — designed for use in laboratories and other environments where vibrating feeders are not allowed due to the presence of corrosive or explosive compounds.

While the basic operating principles of these devices are similar to those of a vibrating hopper, however, the components and mechanisms are different. Instead of an electromagnetic coil mechanism. They rely on pneumatic actuators and piston motors to generate the vibrations necessary for the positioning and orientation of parts.

FLEXIBLE 3D PART FEEDER

With the trend of smart factories and industry 4.0, robots are increasingly widely used and present in many production automation systems. Go with continuous technological change, which requires shorter product life cycles, more new products being updated and launched.

That challenges manufacturing systems to also maximize flexibility to respond to any change. In this case, choosing a robot that comes with a flexible 3D part feeder and a vision camera to accommodate any ever-changing needs is always a priority.

A flexible 3D part feeder is made up of low-frequency vibrating assemblies located below. Based on the direction to be moved, the control system will adjust the frequency and vibration amplitude of these clusters, thereby performing detailed navigation and flipping.

3D flexible part feeder - brand TEMAS is a product researched and developed by Temas Engineering JSC, first launched to the market in October 2020 to meet the needs and trends of the market.

TYPICAL PARTS FOR PART FEEDER APPLICATION

Part feeders are used to locating and orient a wide range of parts, including but not limited to the following parts:

- Bearings parts

- Button

- IC chips, capacitors, electronic components

- Electrical connectors and terminal covers

- Pressed metal parts

- Screws and bolts

- Lids and plastic caps

- Rivets and screws

- Springs

- Food product

- Makeup tools

- Small bottles

With many years of experience in research, production, and part feeders business. We are confident to bring effective and optimal solutions for your application.

Read more

Read more