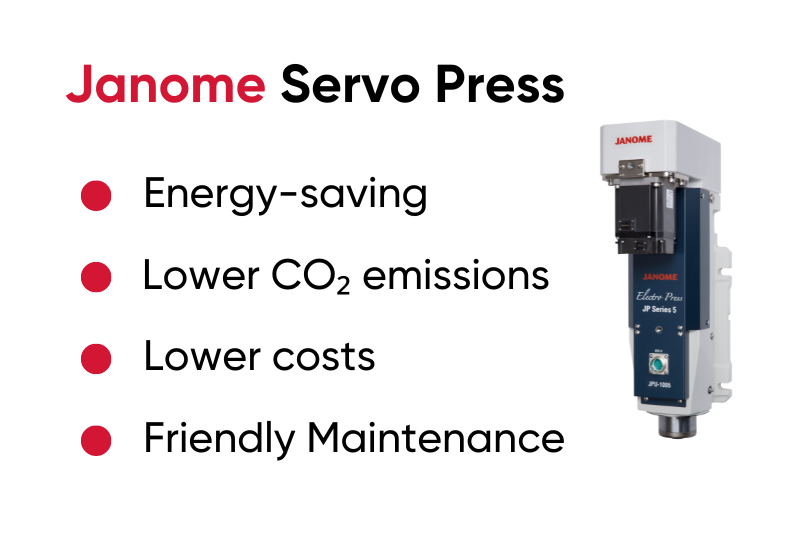

1. Energy-saving & Lower CO₂ Emissions

Environmental & Economical Electro Press uses much less power!

Power Consumption and CO₂ Emission Comparison

Achieving carbon neutrality by 2050 is much more than decarbonizing the supply-side energy sector. It reaches the demand-side industrial, commercial and transportation sectors where the need for both a comprehensive reduction of energy use and energy conversion, the decarbonizing of that energy are key. The Janome Servo Press helps you quickly realize your carbon neutral goals.

2. Energy saving advancements

We made a comparative analysis vs our legacy model to further lower energy usage in our new models.

Uses regenerated energy: Energy-saving design stores up regenerative current in the condenser for lower power loss.

3. Shorter maintenance time

User-friendly maintenance: compared to a burdensome hydraulic press, an electro press greatly reduces your maintenance workload.

We also automated labor-intensive load amp adjustment and load cell calibration, reducing maintenance time by 60%.

4. User-friendly

Low noise, low vibration

Compared with hydraulic presses and pneumatic presses with loud noise and strong vibration, servo presses have the advantage of less noise and low vibration, creating a more comfortable working environment.

No waste oil disposal

No waste oil disposal, cleaner than hydraulic presses and pneumatic presses.

Use existing fixtures

Ideal for small-lot, broad-mix production. Freely set ram speed and stopping parameters (position, load, distance, stop by external signal, etc.) and reduce costs by using your existing peripheral fixtures and metal molds; no need to redesign fixtures or molds.

Streamlined QC

Many precise sensor judgment functions for on-the-spot OK/NOK checking. Upload result data to your PC and configure your own result database for efficient traceability. You can know the result instantly!

5. Designed to lower your total running cost

Looking only at the unit price, a pneumatic or hydraulic press seems less expensive, but add peripheral devices and the other parts and the Electro press helps you break even or better. Over time, power and maintenance for air and oil presses cost more while the Electro Press keeps costs low.

These functions are built into the space-saving “all-in-0ne" design Electro press for easy installation! Total running cost over time after Year 3, the Electro Press costs less!

Environmental impact reduction initiatives!

At Janome, we’re developing ways to make our products more environmentally friendly:

- Less materials: making products smaller and lighter, easy to disassemble with more universal parts.

- Less energy: lower power consumption both when running and when on standby

- Longer life: use highly resilient parts, make software easily upgradeable via external connection

- Less HAZMAT: Compliance with product chemical substance regulation.

In addition to the areas listed above, we’ve implemented our own evaluation standards for developing more environmentally friendly products. Our evaluation standards incorporate these elements:

- Recycling: increase the overall percentage of parts made from recycled metals and reusable plastic, etc.

- Safety: Design to meet standards for chemicals in products such as RoHS*¹, REACH*². UL, CE, KCs, the Japanese Industrial Safety and Health Act, etc.

- Other: Promote unitization and improve assimilability and implementation of universal replacement parts.

We’ve made a comparative evaluation of our newest Electro Press model against our legacy model, and it equals or exceeds its predecessor in all areas. Not only is our newest model better for the environment, it is also designed for operator safety. Our stand-alone two-handed switch control model has a built-in switch box which meets the EN574* standard.

We made these developments without compromising on functionality.

*EN574 is a safety standard for design and selection for two-handed control devices.

In 2011, Janome Group implemented our own “Green Procurement Guidelines” to ensure we comply with the various standards for the use of harmful chemicals in products such as RoHS*¹ and REACH*² at all of our manufacturing facilities. We work with each of our suppliers according to these guidelines to determine if regulated substances are present in the past, and in what amounts to ensure our parts procurement adheres to regulations.

*1 The RoHS Directive, in force in the EU from July 2006, restricts the use of certain hazardous substances in electrical and electronic equipment. These include: lead, mercury, cadmium, hexavalent chromium, PBB (polybrominated biphenyl), PBDE (polybrominated diphenyl ether), DEHP (bis phthalate (2-ethylhexyl)), BBP (butyl benzyl phthalate), DBP (dibutyl phthalate), and DIBP (disobutyl phthalate).

*2 REACH, in force in the EU from June 2007, is a comprehensive regulation for registration, evaluation, authorization and restriction of chemicals.

*Before using our products, please be sure to check their respective operation manuals so that you can use them safety and correctly.

*Specifications may change without notice to improve product quality.

Read more: Servo press JP5

Read more

Read more