What is the SCADA Operating System?

SCADA operating system refers to a system that monitors, controls, and analyzes data for devices from a remote location. At its core, the SCADA operating system enhances industrial efficiency by real-time data collection and processing.

A centralized system provides monitoring and data control access to supervisors. The main purpose of SCADA operating system is to maintain efficiency across various industrial sectors such as manufacturing, transportation, oil and gas, power distribution, industrial plants, etc.

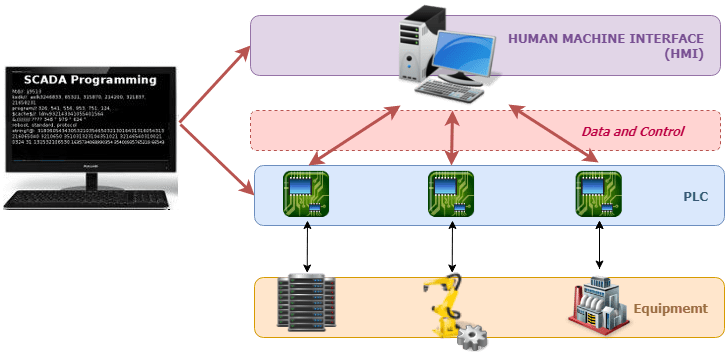

Key components of a SCADA system typically include:

- Human Machine Interface (HMI) software for operator-machine communication

- Data acquisition and control or communication network

- Programmable Logic Controller (PLC) and Remote Terminal Unit (RTU)

- Devices

With the advent of Industry 4.0, SCADA systems have set standards for automation opportunities, especially for enterprises looking to scale up productivity.

4 Core Functions of SCADA Operating System

To empower supervisors and managers to operate facilities remotely, the SCADA operating system primarily provides the following functions:

Data Acquisition

Refers to the process of collecting data, often using conversion procedures such as temperature measurement converted to Celsius and signal transmission in dBm.

Data Transmission and Network Integration

Describes how the SCADA system transmits collected data. Communication channels can be analog (T202, POTS) or digital (RS485, TCP/IP).

Data Presentation

Allows for the collection and synthesis of gathered data for user viewing and decision-making. From tabular presentations to graphical formats, processed data of actions and recorded events create comprehensive, accessible information for users.

Control

Ultimately achieved through Remote Terminal Units (RTUs) and Programmable Logic Controllers (PLCs), enabling system commands such as operational changes or configuration adjustments.

Why SCADA is Essential for Automation?

The SCADA operating system empowers organizations to review pertinent data, evaluate situations, prepare for measured conditions, and execute automated responses within any defined cycle.

Through the precision and accuracy in machine control facilitated by the SCADA system, risks associated with human error are nearly eliminated, making automation a feasible solution.

Essential Features to Seek in SCADA Systems

Programmable Feedback for Sensor Inputs

An efficient SCADA system allows users to program alerts and manage soft controls. Originating from virtual notifications generated through user-defined formulas, these alerts combine complex events monitored by sensor inputs and data reports, such as machine power loss and malfunctioning power sources.

Notification Capability

Programming capability is another crucial feature that enhances SCADA operating system effectiveness. For instance, with 24/7 activated notifications, decision-makers can identify and address situations before network failures lead to any losses.

From emails to text messages and other platforms or methods for alerts, SCADA system notification features are vital for maintaining daily efficiency and emphasizing reliability.

Graphical Interface

This feature is another essential aspect in providing a deep and user-friendly experience within the SCADA operating system interface.

Scalability

Another important consideration, as SCADA systems are a long-term investment. An effective SCADA system will have the capability to support the potential growth of a company over at least a decade.

Rather than frequently replacing operating systems, deploying a scalable and cost-effective solution can reduce the need for transition processes and maintain operational continuity.

Flexible Support for Multiple Protocols, Tools, and Devices

This feature is crucial for the SCADA operating system due to the advantages it can bring across a range of manufacturing industries. For example, automation is facilitated through processes such as collaborative robotics integration.

Hệ Điều Hành SCADA Của Techman Robot Cho Các Giải Pháp Tự Động Hóa

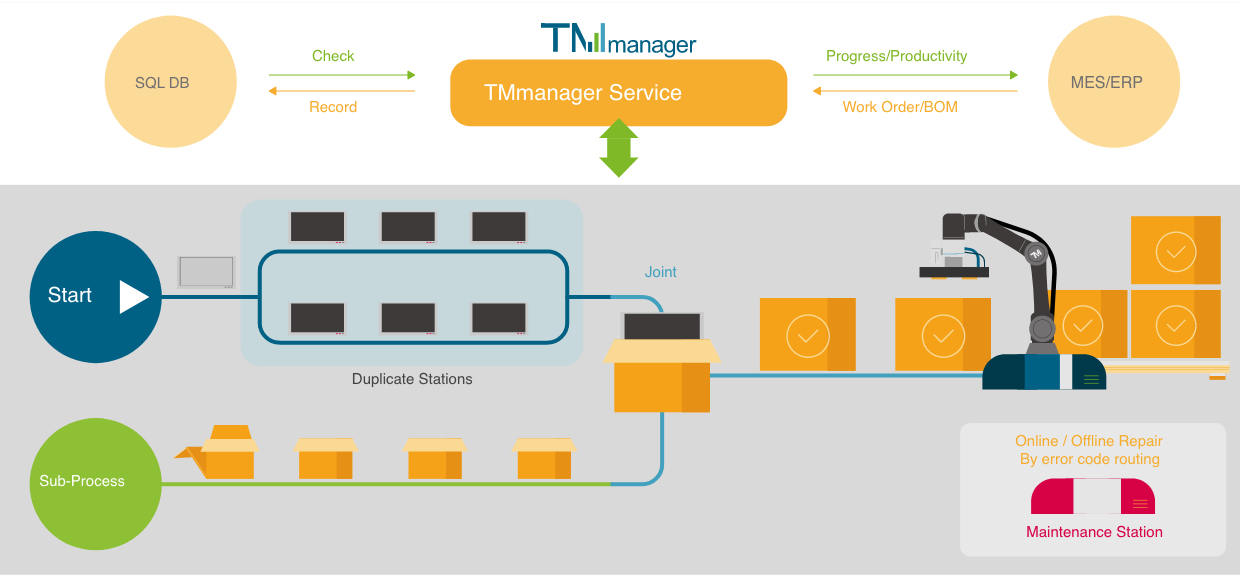

Techman Robot’s TMmanager is your SCADA system for cobot automation, a high-performance factory management software that facilitates easy monitoring, access, and control of factory operations through a variety of solutions such as:

- Usability

- Data security

- Alarm systems

- Open data interface

- Robot management system

- Store floor control system

Temas believes that with suitable applications of robotic technology established, any industry can influence how tasks are performed—enhancing overall efficiency, effectiveness, and cost-efficient productivity.

Read more

Read more