For unlimited picking

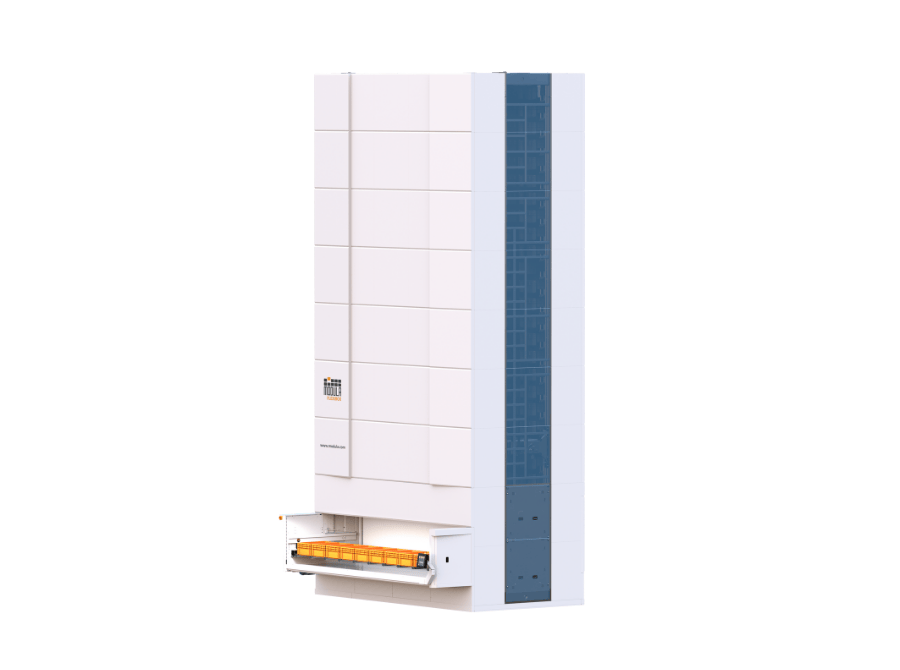

Flexibox is the automated vertical warehouse that manages your bins, processing up to 180 bins per hour to manage hundreds of order lines simultaneously.

It is ideal for order management, kitting and warehousing, because it brings to the operator in the bay only the required products inside the bins, combining them intelligently thanks to the WMS software that governs the process. Once the order has been launched from the management system, the Flexibox warehouse receives the order and prepares all the bins containing the products needed to complete the order by transporting them into the bay to the operator, who can pick up several bins at the same time.

The picking of the bins takes place inside the machine. A central elevator picks up the bins from the warehouse one at a time, according to order requirements, places them with a telescopic fork onto a service tray and, after filling it, brings it to the bay, making all contents accessible to the operator.

According to the machine model, the number of bins that are prepared in the bay can vary from 3 to 9 depending on the tray width.

Scalable, flexible, fast and modular, it is the ideal solution for processing orders quickly and accurately.

Ideal applications for Flexibox technology

Designed for maximum efficiency and throughput in intensive picking environments, Flexibox is the ideal partner when:

- Storage: Maximises the efficiency of height space by storing items in bins/boxes arranged on trays.

- Order processing and picking: Speeds up the preparation of orders in batch picking or multi-order picking modes and provides easy access for operators. While also integrating with handling systems, ensuring faster and more accurate deliveries without errors.

- Kitting: Ideal for assembly lines or production environments where there is a need to collect multiple components for production kits and make them available where needed. In this case, it can also act as a buffer.

Advanced functions for a smart warehouse:

✅ Unrivalled operating throughput: the central elevator and telescopic fork can pick up several bins simultaneously, reducing waiting times and increasing productivity. Up to 9 bins can arrive in the bay at a time for a total of 180 bins/hour. This means hundreds of order lines processed per cycle.

✅ Modula hybrid technology with the Shuttle system: high storage density is combined with the throughput and agility of shuttle systems, ensuring quick access to products.

✅ Simultaneous multi-box management: downtime is reduced by allowing multiple orders to be prepared simultaneously.

✅ Compact for unique storage density: its space-saving design can be up to 20 metres in height to maximise storage capacity while minimising the footprint. The system can manage hundreds of bins in a few square metres of floor space.

✅ Cutting-edge performance at reduced costs: its simple and robust design reduces maintenance, downtime and operating expenses. Unlike other automated solutions that require costly plant modifications, Flexibox is easier to implement, with lower initial costs and a faster ROI.

✅ Fast implementation and scalability: suitable for both small warehouses and large distribution centres, with an easily expandable modular design, Flexibox can grow with your business and the volumes to be handled.

✅ Combinable with other technologies: the system can work efficiently with robots, cobots, AMRs, and advanced picking solutions.

Work side by side with VLMs

Flexibox can work together with our Modula Lift VLMs, offering a comprehensive solution for any product size.

While Flexibox is ideal for small and medium-sized items, our VLMs can handle larger items or large volumes, creating an optimal combination that caters to all requirements

Internal and external

Single or dual delivery level

Flexibox can operate with an internal bay or external bay, offering single or double delivery levels.

The internal bay optimises space, while the external bay maximises picking speed.

The single delivery level provides ergonomic comfort for the operator, while the double level favours efficiency.

Buffer bay

To ensure operators enjoy maximum ergonomics while maintaining high efficiency, the “Buffer Bay” solution can be used.

With this system, a single tray is delivered to the operator on level 1, but at the same time a second tray, complete with the selected bins, is prepared in the rear column ready to be delivered as soon as the previous picking operation is finished.

This mode ensures that picking always takes place at an ergonomic level, eliminating operator waiting time.

Smart orders preparation

Flexibox makes the most of downtime thanks to the automatic “smart orders preparation” mode.

In this mode, the system processes the orders received from the WMS software and prepares a certain number of trays in advance, optimising them for subsequent picking.

All this takes place in total autonomy, without the need for an operator to be present.

When the operator arrives in front of the bay, the trays are already ready, eliminating waiting times and ensuring a fast and efficient workflow. In this way, the machine works at its full potential, guaranteeing extremely high performance peaks.

Fast track: urgent SKU retrivial

Calling for a single item to be sent directly to the bay, bypassing “traditional” orders, is usually more complex in operational contexts where speed is crucial.

One software ecosystem

With the Modula WMS, Flexibox integrates seamlessly into your ecosystem.

Native integration with warehouse management.

Our proprietary Modula WMS solution offers unprecedented advantages that improve efficiency, scalability and intelligence, and is designed to integrate seamlessly with third-party WMS software, optimising the entire operation. Seamless connection is achieved with systems such as ERP, MRP, DMS and DAM. Modula WMS is a single digital ecosystem for all Modula units that offers:

- Simplified operations: a unique and intuitive interface, free of any complexities, only requiring dedicated but quick training.

- Constant updates: synchronised hardware and software updates with clear advantages for the customer. Our WMS takes automation to the next level when combined with intelligence-based solutions.

Designed in combination with artificial intelligence systems

Our WMS takes automation to the next level when combined with artificial intelligence solutions. We are able to:

- Optimise storage with algorithms that dynamically allocate space according to item size, index and rotation frequency, and storage conditions.

- Base batch picking on AI accelerating order processing and reducing labour costs.

The ideal sectors for Modula Flexibox

- Automotive Industry: For high volume SKUs.

- Electronic Commerce: Throughput and accuracy in order processing, scalable operations, high-density storage solution.

- Electronics Industry: Safe and secure storage, options for antistatic environments.

- Retail: High picking speed and fast access to inventory, enhanced customer experience.

- Pharmaceutical Industry: Compliance with regulatory standards, batch and deadline traceability, rapid picking for high demand.

SPECIFICATIONS

| MODEL |

INTERNAL

BAY footprint

|

EXTERNAL

BAY footprint

|

Number of bins per tray

|

| ME - FLEXIBOX |

1,917 x 2,556 |

1,917 x 3,246 |

3 |

| MA - FLEXIBOX |

2,317 x 2,556 |

2,317 x 3,246 |

4 |

| MC - FLEXIBOX |

2,917 x 2,556 |

2,917 x 3,246 |

5 |

| MX - FLEXIBOX |

3,517 x 2,556 |

3,517 x 3,246 |

6 |

| ML - FLEXIBOX |

4,517 x 2,556 |

4,517 x 3,246 |

9 |

| MACHINE |

BINS |

|

Unit heights

3,300 mm to 20,000 mm

|

Bin dimension

400 x 600 mm

|

|

Unit height increment

200 mm

|

Bin payload

Max 35 kg

|

|

Numbers of bays

Up to 3, including above ground level and on the same side

|

Bin height range

120 to 420 mm

|