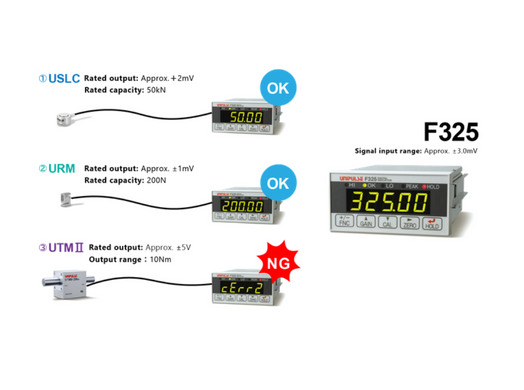

Matching the load cell and the indicator

UNIPULSE's indicators are designed to be able to use with various kinds of load cells. You can check which load cells can be used with indicators in combination by Rated Output of a load cell and Signal Input Range of an indicator.

Case 1: Rated output of USLC is within the signal input range of F325. Thus, the load cell and the indicator can be connected.

Case 2: Rated output of URM is within the signal input range of F325. Thus, the load cell and the indicator can be connected

Case 3: Rated output of UTMII is NOT within the signal output range of F325. Thus, the torque meter and the indicator cannot be connected.

The matching of the load cell and the indicator is done. Now, the settings will differ if you want the rated output to be displayed as "10.00N" or "50.0N", according to the capacity of the load cell you connect.

What is calibrating of indicators?

Calibration setting of indicators is a setting to accurately display measured value from a load cell.

There are some different kinds of Calibration settings.

Span Calibration

Span Calibration is a method to perform calibration by putting balance weight and such on a load cell.

This method, using balance weights, is frequently used for weighing.

While balance weights and spaces for putting those weights are required, Span Calibration can calibrate more accurately than Equivalent Calibration.

Indicators supporting Span Calibration: Almost all UNIPULSE indicators.

Equivalent Calibration

Equivalent Calibration is a method to perform calibration based on voltage information of the rated output of a load cells. The rated output is written on the data sheet etc. that comes with the product upon purchase.

By this method, calibration can be performed without applying load by balance weight and such. It is not necessary to perform both Span Calibration and Equivalent Calibration.

By performing either one of the Calibration method, a load cell and an indicator will be ready for measuring operation.

For force measurement, Equivalent Calibration is used more often due to installation position of load cells or space issues.

For weight measurement, Span Calibration that uses balance weights is used more often. Accurate weights and enough room for putting weights on a scale are required.

It may be difficult to perform Span Calibration, as the weights with either (1) more than the measurement capacity or (2) more than 50% of the rated output of the load cell needs to be prepared.

With indicators for weighing with Equivalent Calibration function, output value that was calibrated by Span Calibration can be stored as a voltage value and used for reconfiguration. It is convenient to use it as a substitution for Span Calibration when it cannot be performed easily such as at replacements and malfunction for load cells or indicators.

Weighing indicators supporting Equivalent Calibration:

| WEIGHING INDICATOR UNIPULSE F701+ | |

| WEIGHING INDICATOR UNIPULSE F701-C | |

| WEIGHING INDICATOR UNIPULSE F701-P | |

| WEIGHING INDICATOR UNIPULSE FC1000 | |

| WEIGHING INDICATOR UNIPULSE F805AT SERIES |

Span Calibration (Linearization Calibration)

There is an error factor called "Non-linearity" on a load cell. By performing Linearization Calibration, such error can be corrected and more accurate measurement can be achieved.

Indicators supporting Linearizing Calibration:

| WEIGHING INDICATOR UNIPULSE FC1000 | |

| WEIGHING INDICATOR UNIPULSE FC400-DAC |

Read more

Read more