Contents

Contents

In modern manufacturing processes, precise press force control is crucial to ensuring product quality, especially in assembly, inspection, or screw-tightening operations.

Challenges in Servo Press Force Control

- Continuous setup is required, especially when adjusting multiple steps in a single process.

- Complex programming is needed to accommodate various conditions such as I/O status, judgment results, and process sequences.

- Even small changes to settings such as force, position, or speed require modifications in the PLC program, which is time-consuming and prone to error.

To address these issues, the PFA Controller was developed as a comprehensive solution combining all essential functions into a single device: servo motor control, data logging, and process monitoring, to OK/NOK signal processing and flexible peripheral connectivity.

All-in-One Functionality

The PFA Controller offers a significant advantage by integrating all the key features required for a modern servo press system:

- Servo motor control

- OK/NOK judgment via waveform comparison

- Press process control via parameter settings

- Data logging, storage, and transmission

- Easy connectivity with peripheral devices

With just one compact unit, users can eliminate complex PLC programming and quickly build systems for pressing, inspection, or fastening tailored to specific requirements.

Flexible System Design

One of the standout features of the PFA Controller is its high flexibility in system design and integration. Instead of being limited to a fixed configuration, it is designed for modular compatibility, allowing users to freely customise the system architecture to match their technical needs and production goals.

PFA supports direct connections to servo motors, ball screws, as well as force and torque sensors, among other peripherals, via I/O or network communication interfaces.

Easy Setup and Operation

Traditional servo control systems often require complex PLC programming, especially when adjusting test conditions or operation sequences. With the PFA, everything is simplified through a touchscreen interface. Users can select a template, enter values for position, force, or speed, and complete the press or inspection sequence setup with ease.

Easy setup of press process parameters

PFA supports “sequential linking,” allowing automatic switching between sequences based on real-time conditions – without any additional programming. For example:

- If result is OK → run program No. 3

- If result is NOK → switch to program No. 4

- Execute program No. 5 three times, then switch to program No. 8 twice

- Repeat program No. 9 until a specific I/O signal turns ON

Versatile Applications

PPFA is not only ideal for servo press applications but also serves as a powerful solution for dedicated inspection machines. Instead of investing in expensive, all-purpose inspection systems, users can build testing equipment tailored to each product type.

In combination with force, torque, and mechanical components, PFA enables the following types of testing:

- Tensile and compressive force testing

- Torque testing

- Bending test

- Strength and rigidity testing

Process sequences can be branched even without a PLC

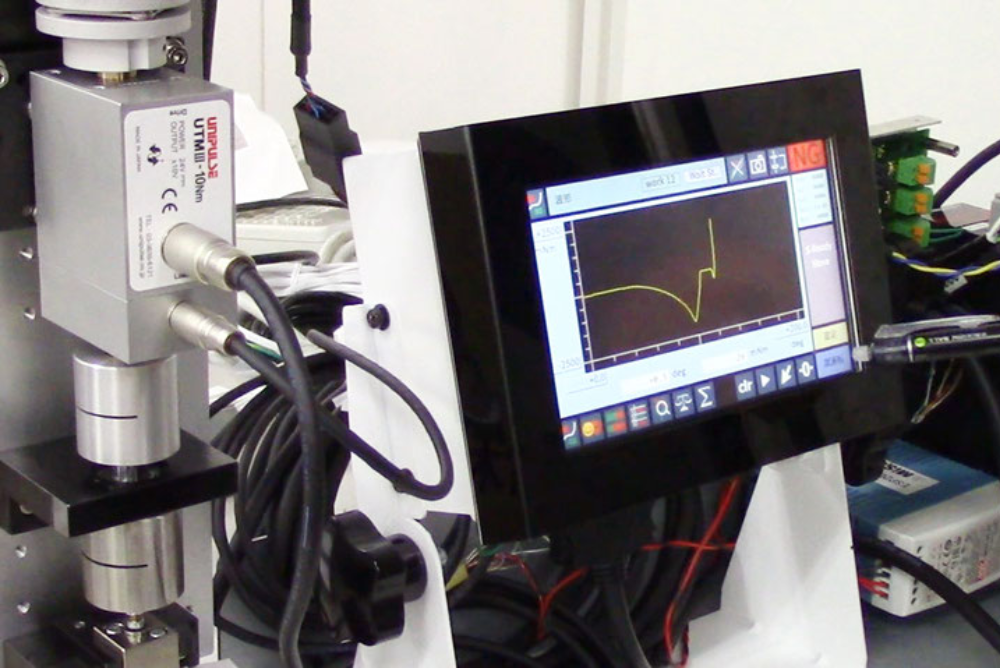

A key highlight is the waveform visualization and comparison feature (force vs. position, torque vs. angle), allowing multi-point judgment and accurate error detection to eliminate NOK products during inspection.

Operator-Friendly Interface

With an intuitive touchscreen interface, even users with little servo control experience can operate the system easily. PFA comes with preset commonly used sequences—just enter values for speed, force, or position to start operations immediately.

Advanced Judgment System

PFA supports simultaneous OK/NOK judgment on two axes—e.g., Force (Y-axis) and Stroke (X-axis)—with waveform display from two input channels and waveform data logging.

Multi-point judgment: OK/NOK status can be evaluated at multiple checkpoints during a single process.

For example, both the start and end points of a pressing cycle can be evaluated simultaneously (up to 5 checkpoints per cycle).

Waveform comparison: If the actual measurement graph exceeds preset High/Low limits, the system automatically flags it as NOK.

Moreover, PFA displays judgment results for both forward and reverse waveform directions. Each judgment condition can be set independently.

Easy Data Connection and Storage

Measurement results and waveform data can be transmitted directly to a server via network for real-time system monitoring. Data can also be stored on an SD card for later retrieval.

Periodic maintenance is supported by displaying statistical values such as Zero point and Hold value, allowing users to quickly detect abnormalities, prevent failures, and optimize production.

Technical information

| Common specifications | |

| Power supply voltage | DC24V(±15%) |

| Power consumption | 20W typ. |

| Operation condition |

Operation temperature: -10℃ to +40℃/ Storage temperature: -20℃ to +60℃ Humidity: 85% RH or less (non-condensing)

|

| Dimensions | 218(W) x 140(H) x 87(D) mm (Projections excluded) |

| Weight | PFA10: Approx 2.5kg PFA7: Approx1.8kg |

| CE marking certification | EMC Directives EN61326-1 |

With its servo motor control capability, graphical data analysis, accurate OK/NOK judgment, and robust system communication, the PFA Controller is an ideal solution for businesses looking to optimize servo-driven pressing, inspection, or assembly processes.

By integrating all essential functions into one compact unit, PFA simplifies control system design, reduces initial investment, and ensures easy expansion and maintenance in the future. Whether you're building an assembly press line or a product quality inspection machine, the PFA will be your trusted partner in advancing manufacturing automation.

Reference: PFA Controller

Read more

Read more