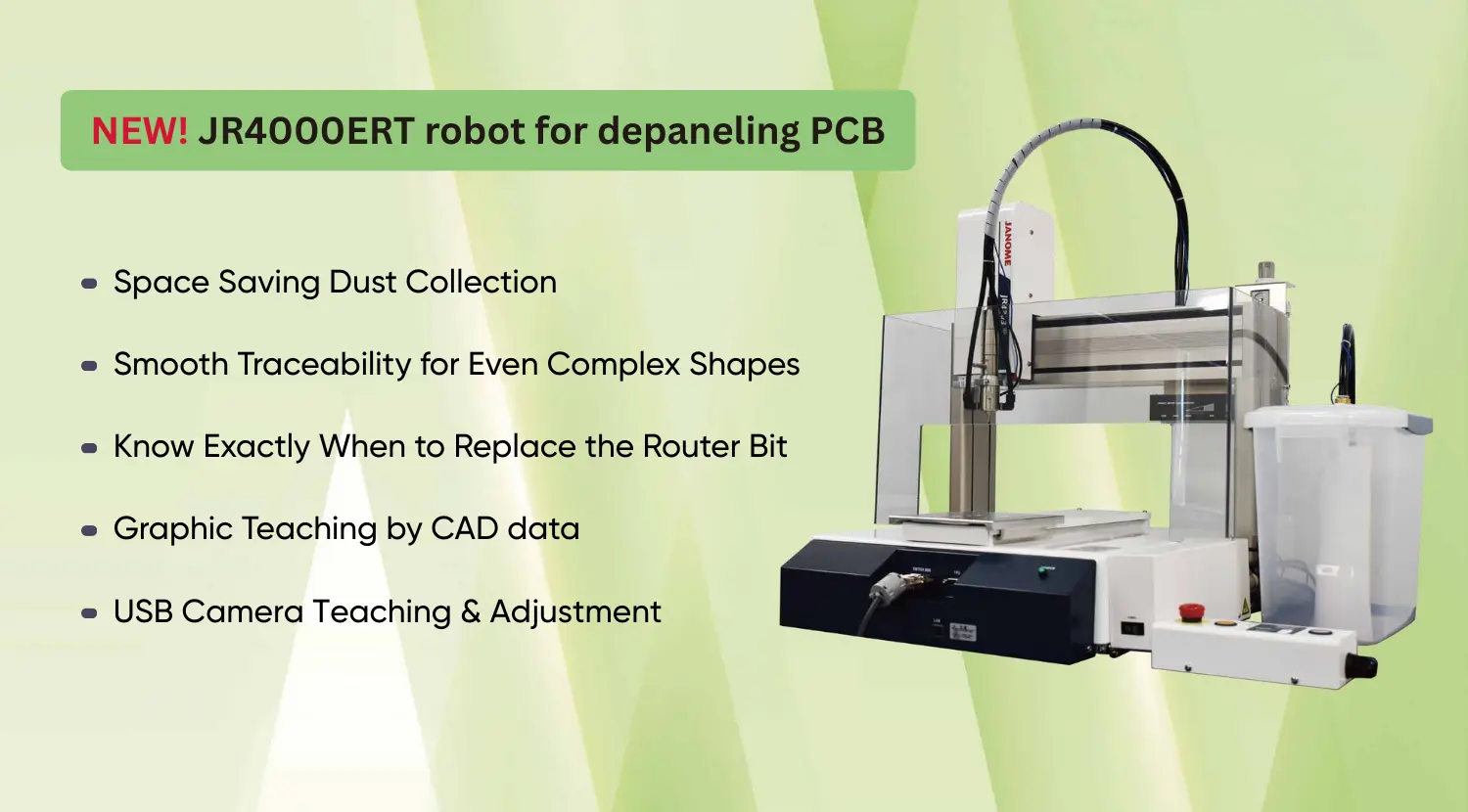

The Janome JR4000ERT Series is a new-generation desktop robot specifically designed for PCB depaneling.

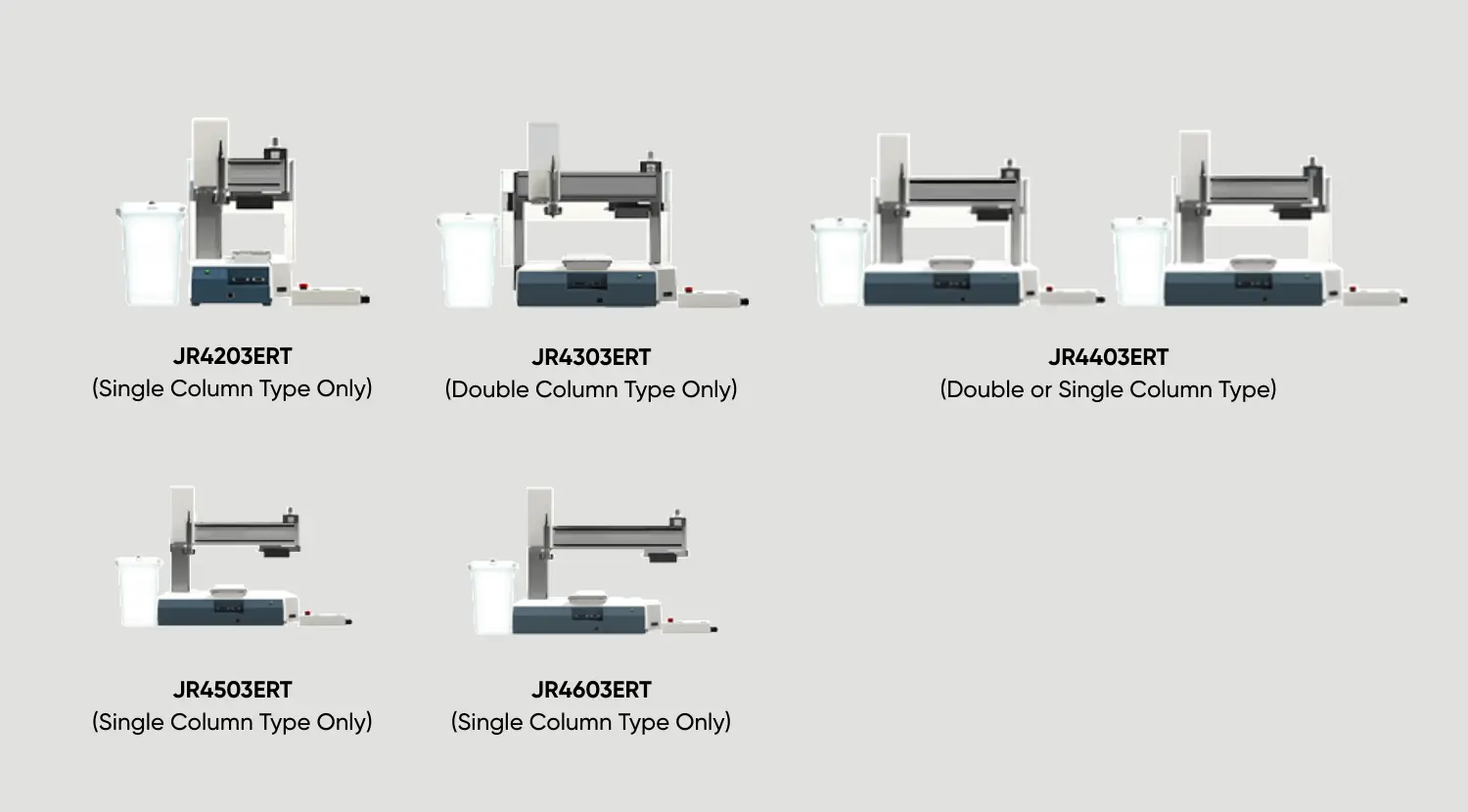

Model: JR4203ERT, JR4303ERT, JR4403ERT, JR4503ERT, JR4603ERT

The Janome JR4000ERT Series is a new-generation desktop robot specifically designed for PCB depaneling. Equipped with a spindle motor for router cutting, the system delivers high-precision PCB contour processing with smooth cut edges while minimizing mechanical stress on the board.

Building on the proven stability of the previous JR3000ERT Series, the new JR4000ERT Series features major upgrades in accuracy, speed, safety, and intuitive programming

The router cutting method minimizes stress on PCBs while creating smooth cutting edges.

With advanced CP control, the high-performance robot ensures consistent and precise cuts, from curves to straight lines.

Overhead dust collection is integrated directly into the robot head. No external dust collector required.

Ideal for space-constrained environments and optimized production line layouts.

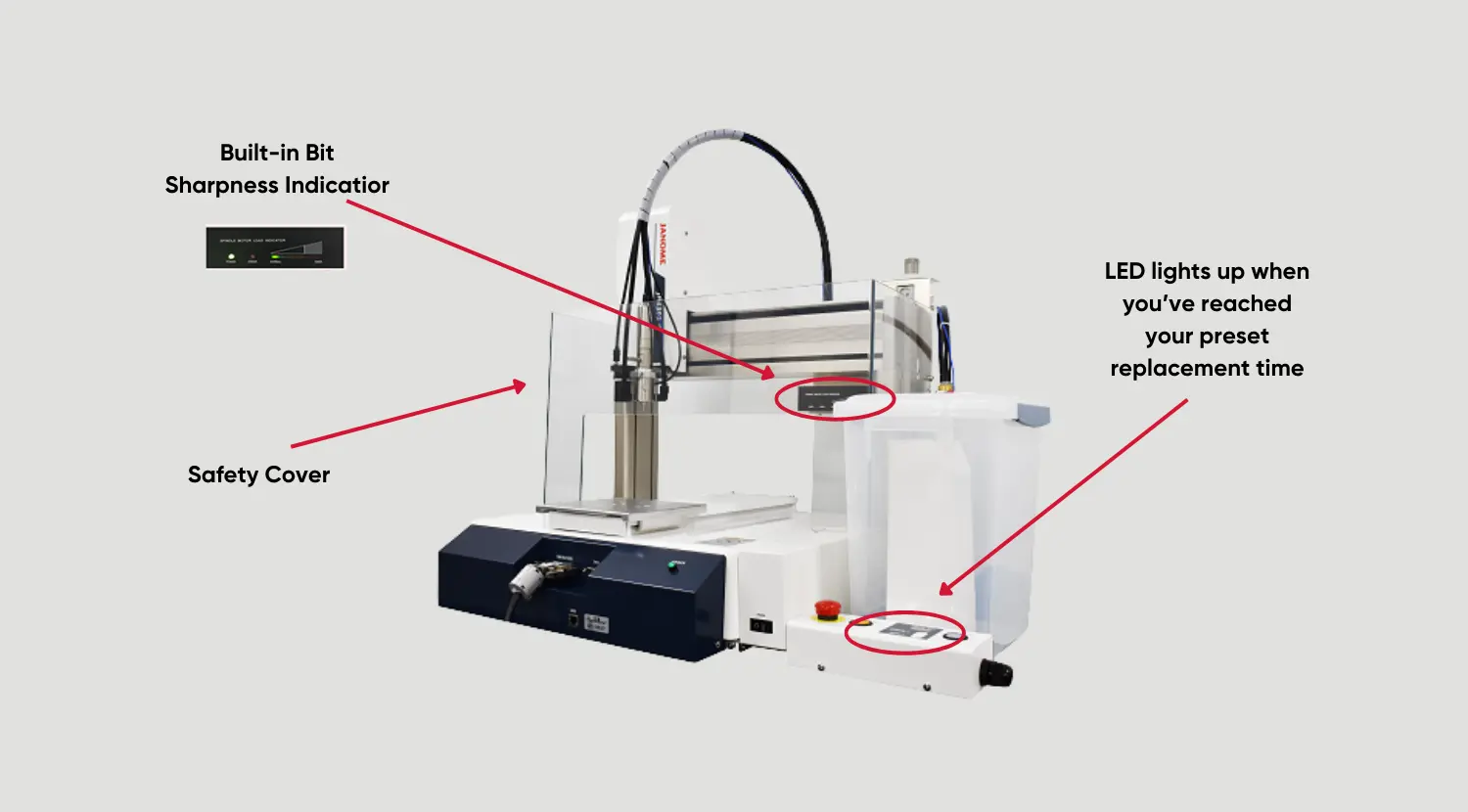

A customizable Notification Timer allows users to set blade replacement intervals proactively.

LED indicators on the switch box alert operators when replacement is due, helping maintain cutting quality and prevent unplanned downtime.

Automatic detection of abnormal cutting loads and position errors with immediate stop in case of faults

Cutting torque is displayed via an indicator for easy process monitoring.

Optional safety cover* enhances operational safety.

*Note: The safety cover is optional for the JR4503ERT. The JR4603ERT is not equipped with a safety cover, users must prepare a suitable safety enclosure.

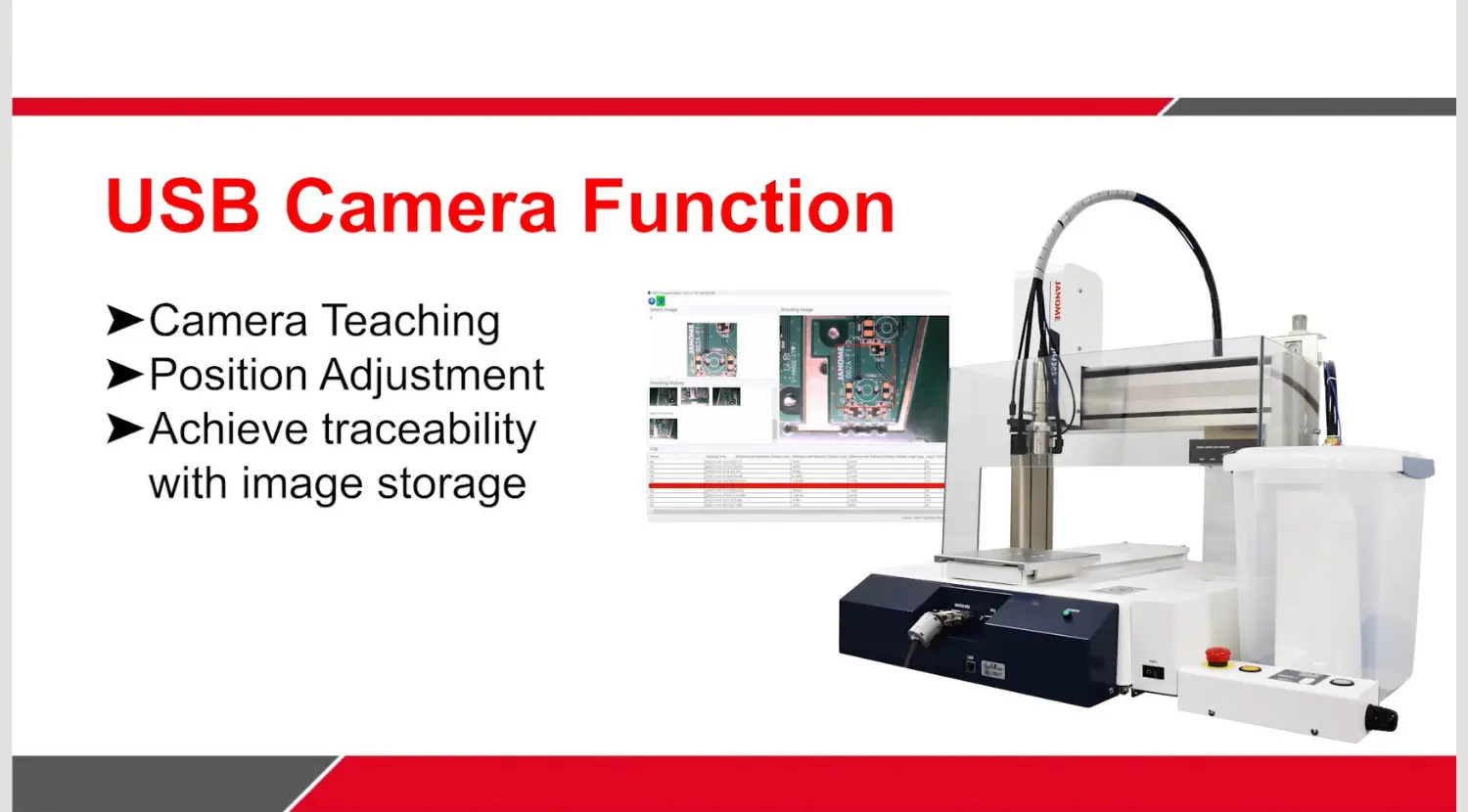

The JR4000 Series supports position correction (offset correction) using a USB camera (optional).

When workpiece position shifts, the system:

No dedicated industrial camera required, reducing system cost while maintaining high accuracy.

Correction results can be saved for traceability and reporting.

JR C-Points III is Janome's proprietary program input system for creating, editing, and saving teaching and customization data on a PC.

New UI design:

Main software areas:

CAD-based graphic editing

Tool Offset Function

Multi-language support

*Compared to the previous generation. Not applicable to models with a 200 mm XY stroke.

PCB depaneling for:

Well-suited for environments requiring:

| JR4203ERT | JR4303ERT | JR4403ERT | JR4503ERT*5 | JR4603ERT*5 | ||

|---|---|---|---|---|---|---|

| Depaneling Range Limit | X, Y Axes | 195 x 195mm | 295 x 315mm | 395 x 395mm | 505 x 505mm | 505 x 615mm |

| Z Axes | 35 mm | 90 mm | 82 mm | 95 mm | 95 mm | |

| Max. PTP Speed*1 | X, Y Axes | 700 mm/s | 1000 mm/s | |||

| Z Axes | 250 mm/s | 400 mm/s | ||||

| Max. CP Speed*1 | X, Y, Z Combined | 600 mm/s | 850 mm/s | |||

| Cutting Trajectory Precision | 0.2 mm (nominal standard) | |||||

| Repeatability*2 | X Axes | ±0.006 mm | ±0.007 mm | ±0.008 mm | ±0.008 mm | |

| Y Axes | ±0.01 mm | |||||

| Z Axes | ±0.008 mm | |||||

| Applicable Board Materials | Glass Epoxy, Paper Phenol, etc. (maximum board thickness 1.6 mm) | |||||

| Power Source | AC100~120V±10% / AC200~240V±10% (single phase) | |||||

| Power Consumption | 250W | |||||

| Supplied Air Pressure*3 | 0.5~1.0Mpa (5~10kgf/cm²), Dry Air | |||||

| Air Consumption Volume*4 | 200Nℓ/min | |||||

| Spindle Motor | Rated Rotating Speed: 40,000rpm | |||||

*1 Maximum speed can vary depending upon conditions.

*2 Repeatability was measured at a constant temperature for the robot unit only and does not represent a guarantee of absolute precision.

*3 Be sure to use dry air. Supplying air containing moisture or oil can damage the device.

*4 If the flow rate is insufficient, vacuum pressure will decrease during operation, reducing dust collection efficiency. Therefore, ensure a flow rate of 200 Nℓ/min is supplied.

*5 The safety cover is optional for the JR4503ERT. Also, the JR4603 does not come with a safety cover. Please prepare a safety cover at the user side.

*CE specifications are not supported.

*Specifications may be modified without prior notice to improve product quality.