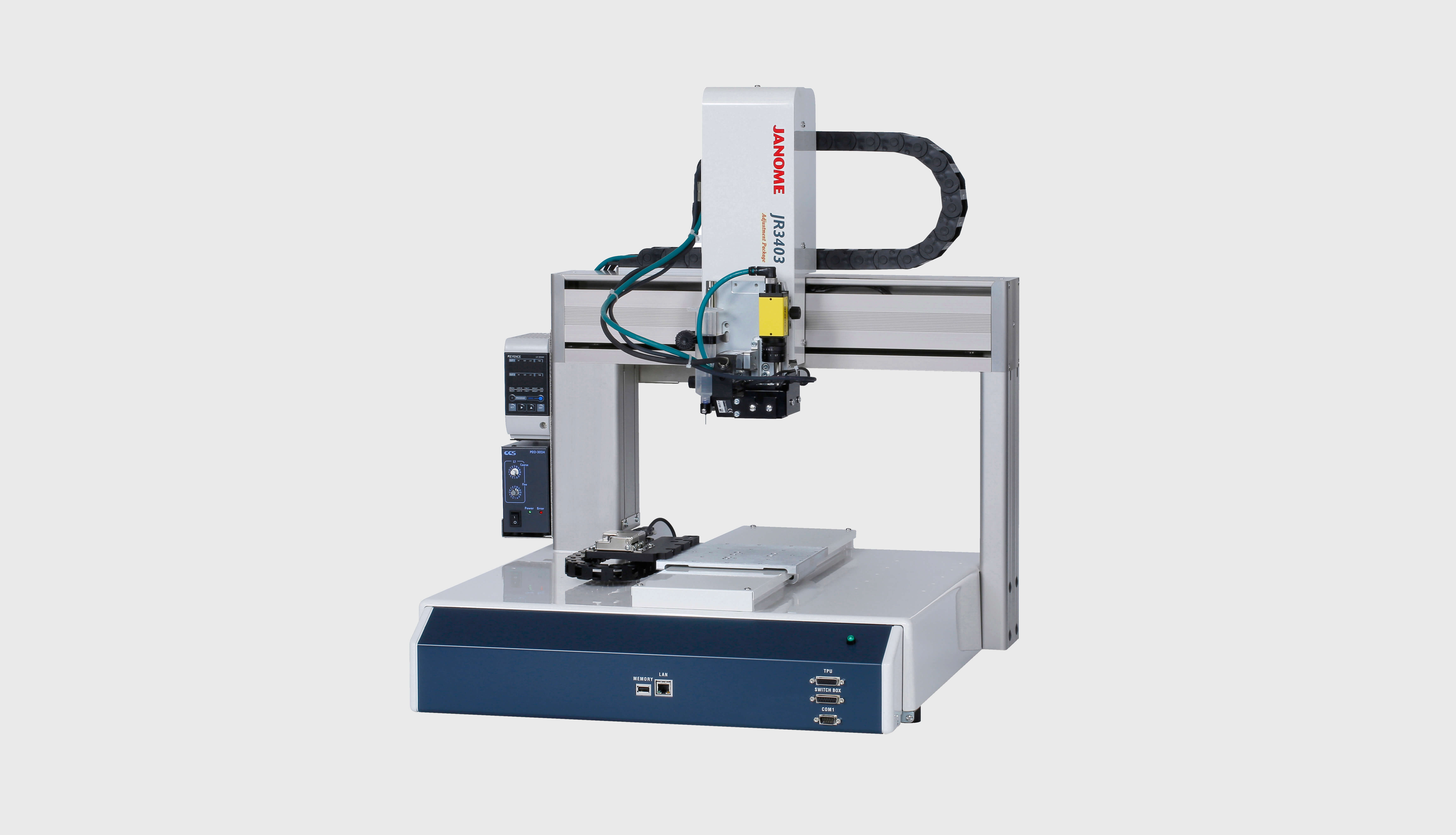

Dynamic Adjustment Package Dispensing Robot

Model: JR3303AP-D, JR3303AP-D, JR3304AP-D, JR3404AP-D

| Model | JR3303 | JR3403 | JR3304 | JR3404 | |

| Column Type | Double | ||||

| Number of Axes | 3 Axes Synchronous Control | 4 Axes Synchronous Control | |||

| Operating Range | X・Y Axes (mm) | 300 x 320 | 400 x 400 | 300 x 320 | 400 x 400 |

| Z Axis (mm) | 100 | 150 | 100 | 150 | |

| R Axis (°) | - | ±360 | |||

| Maximum Portable Load (kg) | Workpiece | 14 | |||

| Tool | 5 | ||||

| Maximum Speed*1 | X Axis (mm/sec) | 900 | |||

| Y Axis (mm/sec) | 800 | ||||

| Z Axis (mm/sec) | 400 | ||||

| R Axis (°/sec) | - | 900 | |||

| Maximum Speed*1 | X・Y・Z Combined Speed (mm/sec) | 850 | |||

| Acceptable Moment of Inertia (kg・cm2) | - | 90 | |||

| Robot Repeatability*2 | X,Y,Z Axis (mm) | ±0.007 | ±0.01 | ||

| R Axis(°) | - | ±0.008 | |||

| External Dimensions | W x D x H (mm) (excluding cables and protrusions) |

628 x 608 x 657 | 651 x 668 x 715 | 628 x 608 x 769 | 651 x 668 x 844 |

| Open Height (mm) | 200 | 208 | 275 | 300 | |

| Robot Weight (kg) | 42 | 51 | 44 | 55 | |

*1 Maximum speed can vary depending upon conditions.

*2 Repeatability was measured at a constant temperature and does not represent a guarantee of absolute precision.

| Drive Method | 5 phase pulse motor drive (encoder added as an option) | |

|---|---|---|

| Control Method | PTP (Point to Point) control, CP (Continuous Path) control | |

| Interpolation | 3-dimensional linear and arc interpolation | |

| Teaching Method | Simple and versatile teaching using our original software | |

| Teaching System | Online teaching from your PC using our dedicated software | |

| Screen Display Options | Measurement Units | mm/inch |

| Languages | English・German・Japanese・Simplified Chinese・Traditional Chinese | |

| Program Capacity | 999 programs | |

| Data Capacity*3 | Up to 32,000 Points | |

| Simple PLC Function | Up to 100 programs, with up to 1,000 steps/program | |

| External Input / Output*4 |

I/O-SYS | 16 Inputs, 16 Outputs |

| I/O-1 | 8 Inputs, 8 Outputs (including 4 relay outputs) | |

| I/O-S (optional) |

For connection to interlocking devices such as area sensors, etc. | |

| I/O-MT (optional) |

Controls up to 2 external motors | |

| Fieldbus (optional) |

CC-Link, DeviceNet, PROFIBUS, EtherNet/IP, PROFINET, CANopen | |

| COM | RS232C 3ch (for external devices, COM commands) | |

| MEMORY |

For USB memory connector

|

|

| LAN | For PoE Industrial Hub connection | |

| Camera Dispensing Specifications Attachments*5 | Camera set, CCTV Lens set & Closeup Ring set, Lighting set, Laser Displacement Sensor set, PoE Industrial Hub, Needle Adjuster (3-Axes Type or 4-Axes Type), Dispenser Base Unit | |

| Power Source | AC100-120V/AC200-240V ±10% (Single Phase) | |

| Power Consumption | 280W | |

| Operating Environment |

Temperature | 0-40℃ |

| Relative Humidity | 35-85% (Without condensation) | |

| Elevation | up to 1,000m | |

*3 Point data capacity reduces as the total function data setting/point job data/sequencer data increases, due the shared data storage area.

*4 Some I/O are assigned in advance at the factory for system configuration purposes.

*5 We ask that customers please prepare the PC (and connecting cable) and dispenser at their end.