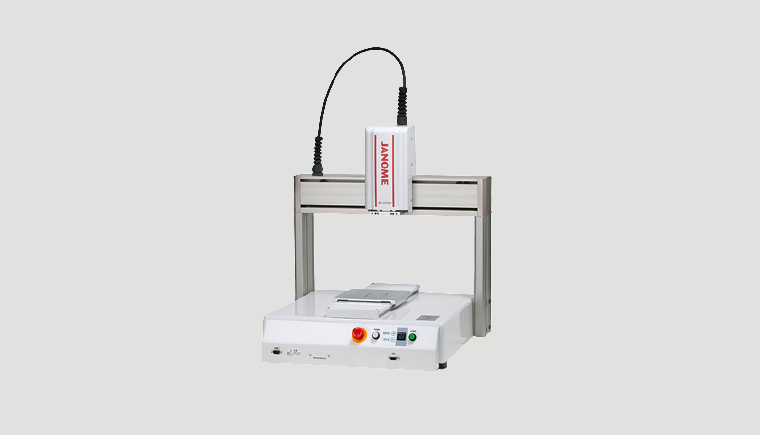

3-axes desktop robot features refined functions at economic price

Model: JR-V2203, JR-V2303, JR-V2403

| Model | JR-V2203 | JR-V2303 | JR-V2403 | ||

| Number of Axes | 3 (Synchronous Control) | ||||

| Operating Range | X・Y Axes (mm) | 200×200 | 300×320 | 400×400 | |

| Z Axis (mm) | 50 | 50 | 100 | 100 | |

| Maximum Portable Load | Workpiece(kg) | 5 | |||

| Tool(kg) | 2*1 | ||||

| Maximum Speed *2 |

X・Y Axes (mm/sec) | 500 | |||

| Z Axis (mm/sec) | 200 | ||||

| Maximum Speed *2 |

X・Y・Z Combined Speed(mm/sec) | 500 | |||

| Repeatability*3 | X・Y・Z Axes (mm) | ±0.01 | |||

| Dispensing Specifications | Dimensions WxDxH(mm) |

320×364×549 | 560×507×609 | 560×507×655 | 584×607×755 |

| Body Weight (kg) |

17 | 30 | 31 | 37 | |

| Screw Tightening Specifications | Dimensions WxDxH(mm) |

320×443×549 | 560×590×609 | 560×590×655 | 584×650×755 |

| Body Weight (kg) |

18 | 31 | 32 | 38 | |

| Standard Specifications | Dimensions WxDxH(mm) |

320×364×549 | 560×507×609 | 560×507×655 | - |

| Body Weight (kg) |

17 | 30 | 31 | - | |

*1 We've prepared a "High Payload Type" which can bear a tool weight up to 3kg. Please see the chart below for available models.

*2 Maximum speed can vary depending upon conditions. The robot cannot reach maximum speed when bearing the maximum portable load.

*3 Repeatability was measured at a constant temperature, so absoluted precision is not guaranteed.

Lineup

| Tool weight | Model | JR-V2203 | JR-V2303 | JR-V2403 | |

|

Specifications Z Axes |

50mm | 50mm | 100mm | 100mm | |

| Regular Payload Type (max. portable load 2kg) |

Dispensing | 〇 | 〇 | 〇 | 〇 |

| Screw Tightening | 〇 | 〇 | 〇 | 〇 | |

| Standard | 〇 | 〇 | 〇 | - | |

| High Payload Type (max. portable load 3kg) |

Dispensing | 〇 | 〇 | - | - |

| Screw Tightening | 〇 | 〇 | - | - | |

| Standard | 〇 | - | - | - | |

〇: Available

| Drive Method | 2 Phase Pulse Motor | |

|---|---|---|

| Control Method | PTP (Point to Point) control, CP (Continuous Path) control | |

| Interpolation | 3 dimensional linear and arc interpolation | |

| Teaching Method | Remote Teaching (JOG), Manual Data Input (MDI) | |

| Teaching System | ・Direct teaching using the optional teaching pendant ・Off-line teaching with JR C-Points software from a PC |

|

| Program Capacity | 255 Programs | |

| Data Capacity*4 | Up to 30,000 Points | |

| External Interface 【Common】 |

Dedicated Teaching Pendant Interface (RS422) Dedicated PC Interface (RS232C) 1ch (for external devices COM2,COM3)2ch(optional) |

|

| External Input/Output*5 | Dispensing Specifications | I/O-SYS: 8 Inputs, 8 Outputs I/O-DSP: 1 Input, 2 Outputs (including 1 relay output) Needle Adjuster Connector(optional) |

| Screw Tightening Specifications | I/O-SYS(for Screwdriver Connection) 8 Inputs/8 Outputs * 2 Outputs are for the Ejector I/O-1 8 Inputs/6 Outputs |

|

| Standard Specifications | I/O-SYS 8 Inputs/8 Outputs I/O-1 8 Inputs/6 Outputs(optional) |

|

| Simple PLC Function | Up to 100 Programs (1,000 Steps/Program) | |

| Power Source | AC90~132V/ AC180~250V (Single Phase) | |

| Power Consumption | 150W | |

*4 Point data memory capacity reduces as additional function data settings/point job data/sequencer data are added, due to the shared data storage area.

*5 I/O polarity type is NPN only.

| Dispensing Specifications | Purge Switch(dedicated switch on front panel) Start Box Specifications (inclusion of purge switch) |

|---|---|

| Screw Tightening Specifications*6 | Maximum Tightening Torque 0.2Nm(2kg・cm) Recommended Screw Size M1.0~M2.0 (provided the maximum tightening torque is not exceeded.) Ejector/Regulator included as standard equipment (for screw pickup) Screw Tightening set includes: Screw Tightening Spec Robot, electric screwdriver and automatic screw feeder. |

| Standard Specifications | I/O-1 attachachable as an option |

*6 Maximum tightening torque must not exceed 0.2Nm.